TRANE

R

Assembly & Installation

Chilled Water

Piping - Coil Connection

General Coil Piping Recommendation

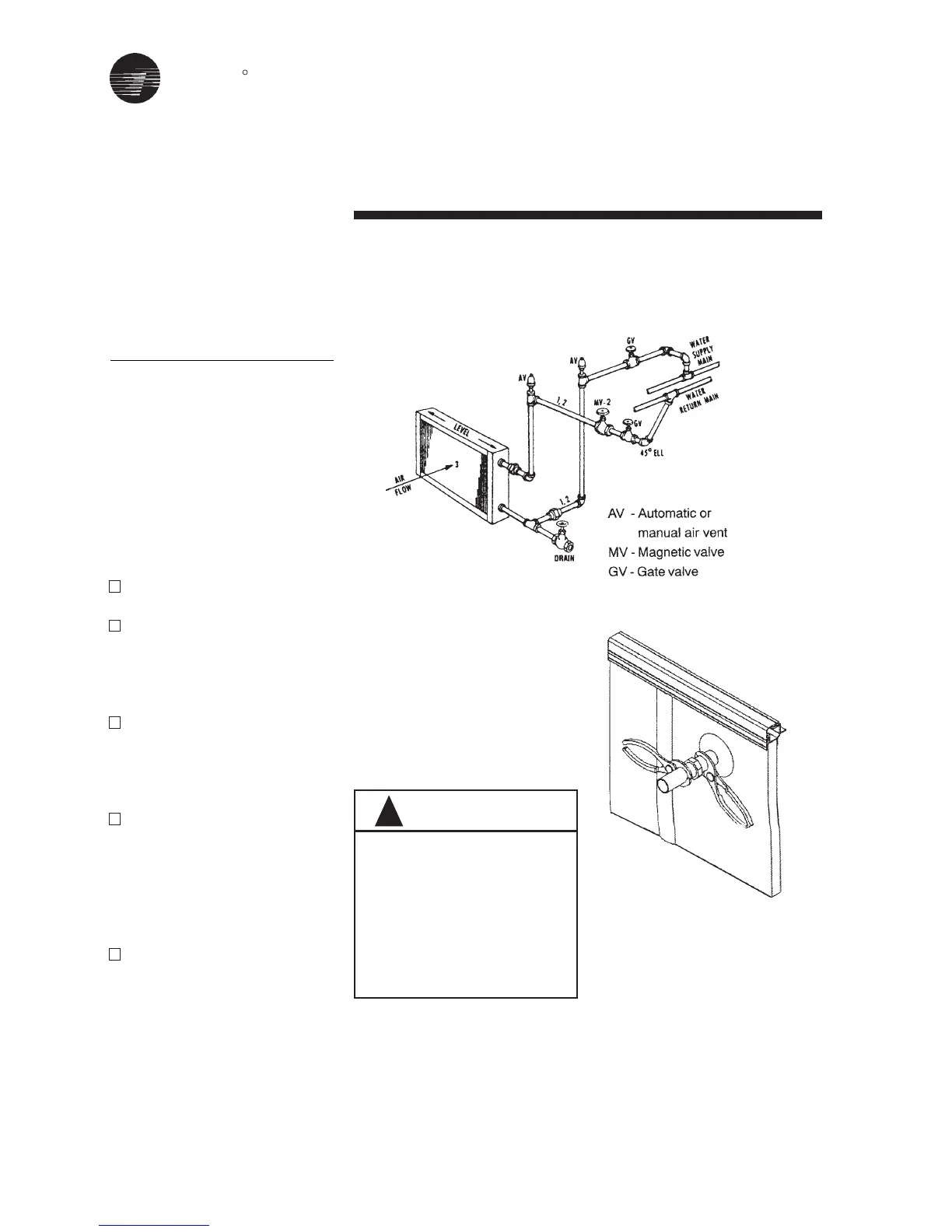

Refer to Figure 11 for typical cooling /

heating and steam coil piping.

Proper installation, piping and trapping

is necessary to assure satisfactory coil

operation and to prevent operational

damage. Water inlet and outlet

connections protrude through the coil

section side panel. Follow standard

piping practices when piping to the

coil. Note the following:

1. Support all piping independently of

the coils.

2. Provide swing joints or flexible

fittings in all connections that are

adjacent heating coils in order to

absorb thermal expansion and

contraction strains.

3. When attaching piping to the coil

header, make the connection only

tight enough to prevent leaks, the

maximum recommended torque is

200ft-lbs.

4. Teflon tape or teflon piping

compound should not be used

because of its high lubricity, teflon

makes it easier to tighten the pipe

to the header joint past the point

where an effective seal is created,

thus damage to the coil could result.

5. "White Zinc" compound / pipe

sealer on all threaded connection

is recommended, instead.

20

NOTE: DRAIN AND VENT CON-

NECTIONS ARE PROVIDED AS

STANDARD ON COIL HEADERS.

IF EXTENDED DRAINS AND VENTS

ARE REQUIRED, THEY MUST BE

FIELD PROVIDED.

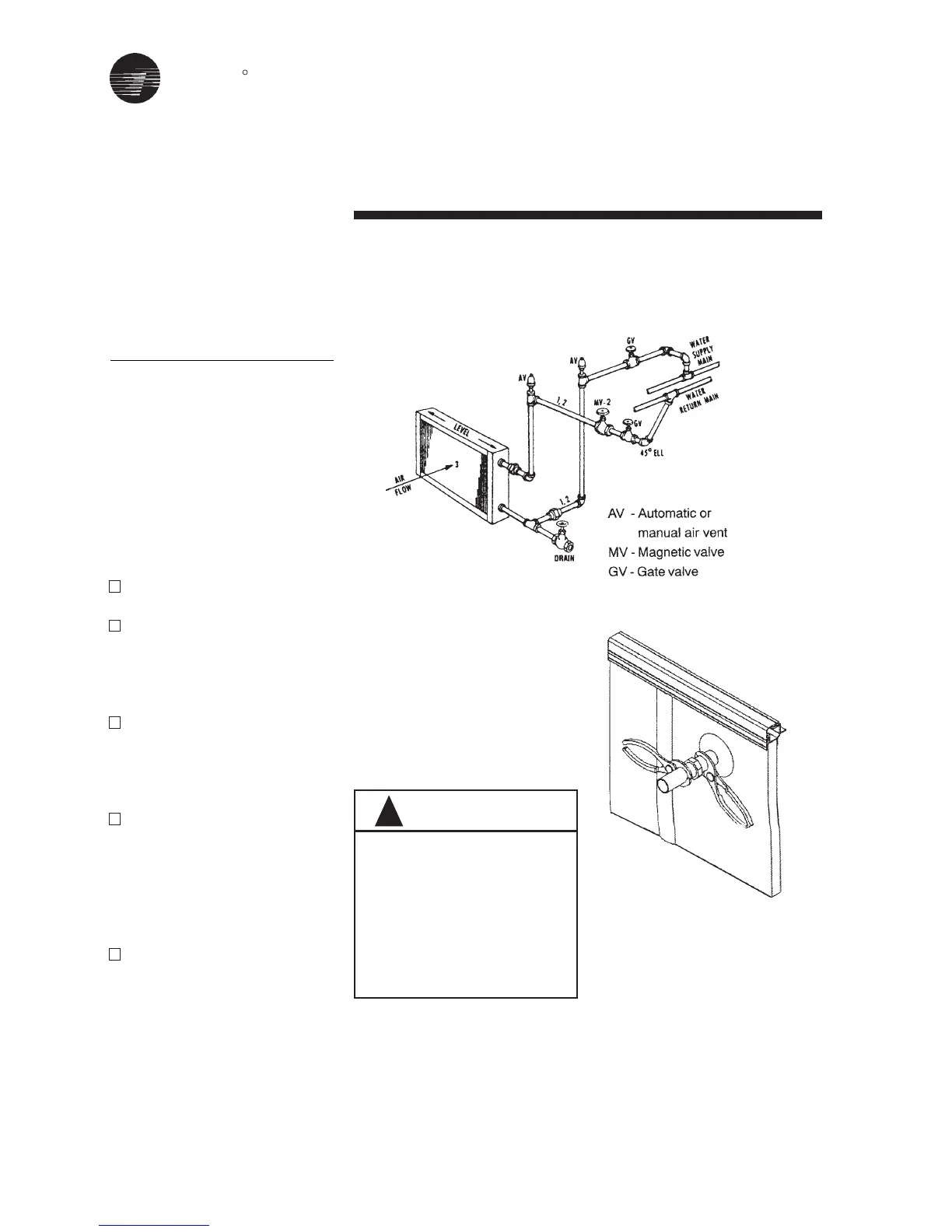

Figure 12

Completely stress-free connections

are essential. The pipework of the coils

should be arranged to facilitate easy

removal of the coil for any required

maintenance purposes.

Figure 11

Typical Piping for Water Coil

IMPORTANT

!

To avoid damaging the coil

connections it is essential to grip

the pipe connection whilst

applying counter pressure to

tighten the joint (see Figure 12).

Use “Back-up wrench” when

attaching piping to coils, on

threaded connections.

Loading...

Loading...