ACC-APG002A-EN

33

General Support Sequences

Fan Setpoints with ERM-driven Fan Types

When a system is equipped with an External Rotor Motor (ERM), the minimum and maximum ERM

parameters can be adjusted to tune the airflow to meet the application requirements.

In addition to this, the Symbio™ 700 supports setpoints that can adjust airflow as needed:

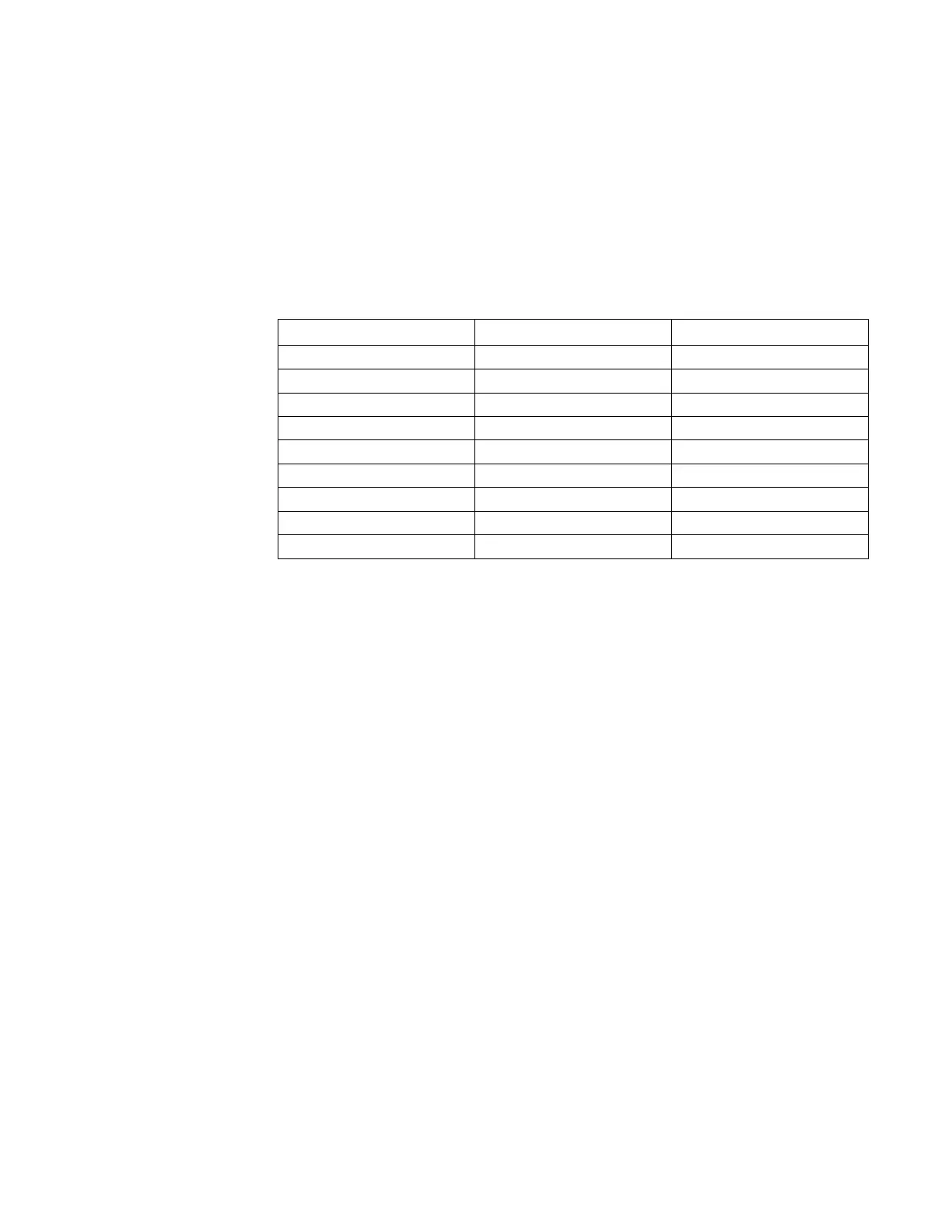

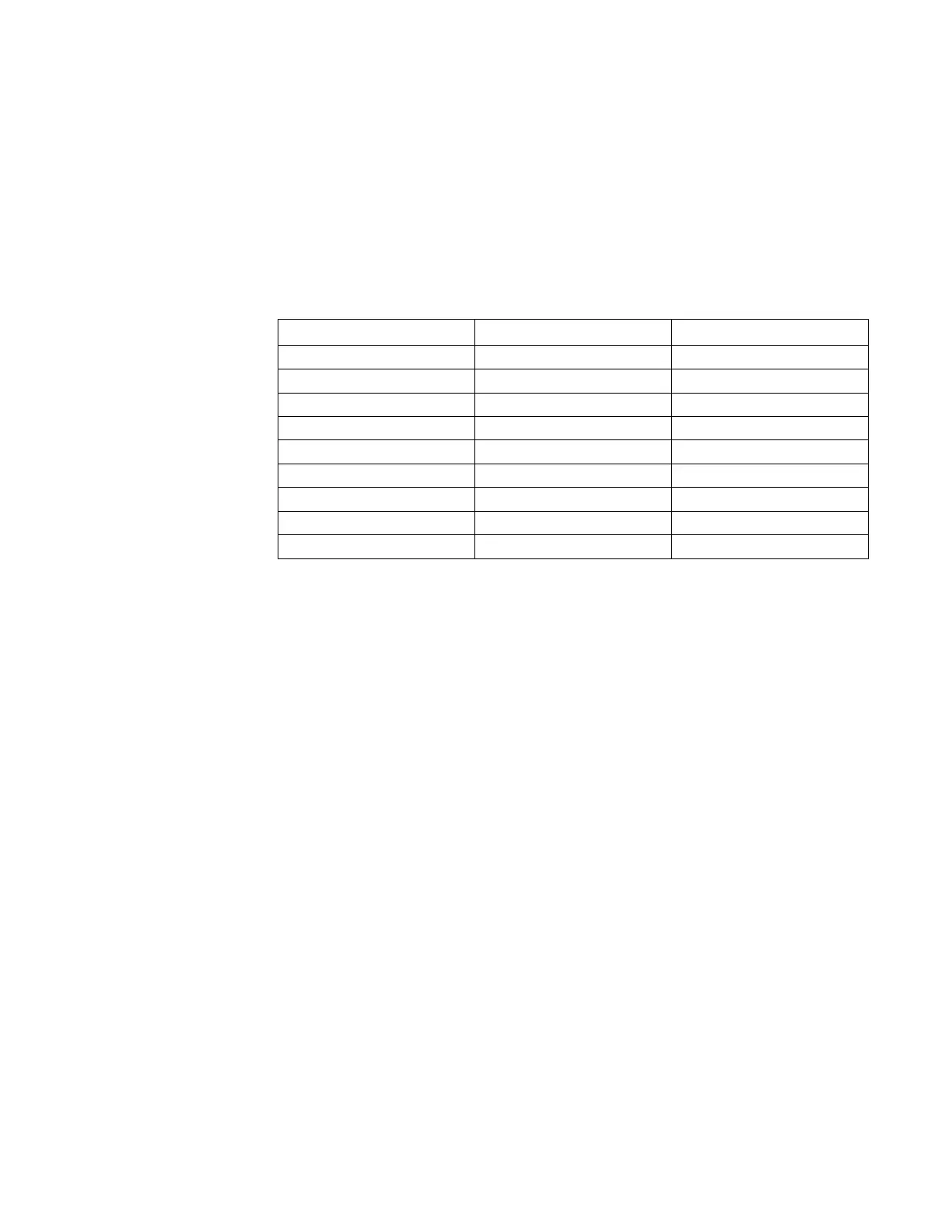

• Supply Fan Maximum Speed Setpoint

– Range: Determined by unit tonnage. See table below.

Unit Size (tons) Range (%) Default (%)

6 38-100 71

7.5 42-100 75

8.5 44-100 75

10 51-100 83

12.5 50-100 77

15 41-100 75

17.5 44-100 74

20 48-100 78

25 51-100 79

– Operation: This setpoint “trims” the maximum fan speed, based on the configured maximum

ERM rpm.

– Example: rpm max = 1940 rpm

• Supply Fan Maximum Speed Setpoint @ 75% yields a maximum of 1358 rpm ERM output.

• Effective ERM Max (to be used in Supply Fan Minimum Speed Setpoint application) will be

set to 1358 rpm.

• Supply Fan Minimum Speed Setpoint

– Range: 0-100%

– Operation: 0-100% over minimum to effective maximum ERM configured fan speed

– Example: ERM Min = 0 rpm, Effective ERM Max = 1940 rpm

• Supply Fan Minimum Speed Setpoint @ 50% yields 970 rpm ERM output.

• Minimum and Maximum Speed Setpoints interact to ensure that the minimum defined fan speed at a

given equipment operating condition is maintained.

Compressor Minimum Runtime

Under all normal running conditions, a 3–minute minimum ON and OFF timer is maintained for each

compressor. Once a compressor is turned ON, it remains on for a minimum of 3 minutes. Once a

compressor is turned OFF, it remains off for a minimum of 3 minutes. System overrides that require

immediate shutdown of the equipment, test modes, and compressor diagnostics/protection functions

can override these 3–minute timers. However for normal temperature and thermostatic-based control,

these minimum ON/OFF timers are maintained.

Compressor Proof of Operation

For each compressor. a Compressor Proving binary input is used to monitor the state of an auxiliary

switch that is used to indicate compressor motor contactor status. Under normal operation, detected

operation indicates that all safety devices within the compressor safety circuit are in their normal state.

The switch operates as OPEN when the compressor motor is OFF and CLOSED when the compressor

motor is ON.

Loading...

Loading...