1

/

2

” (12.7mm) Comb Template

(25.4mm pitch with Symmetrical Sockets)

No. of Sockets

1 2 3 4 5 6 7 8 9...

38.1 63.5 88.9 114.3 139.7 165.1 190.5 215.9 241.3

Optimum width of timber in mm

ie (Pitch x No. of Sockets) + 12.7mm = Width.

DJ300

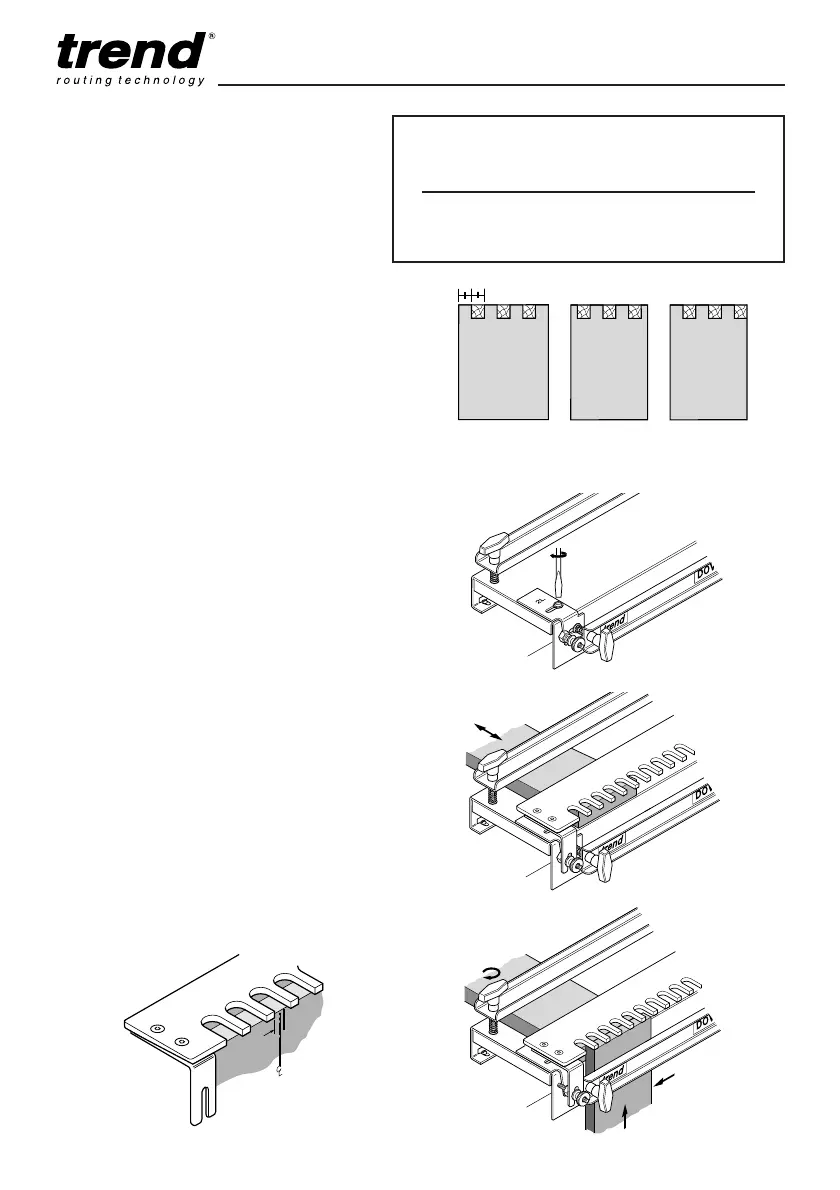

Setting up the Jig

■ Fit the edge guides marked No. 2 and leave

slightly loose.

■ Fit the comb template to the jig.

Slide a packing piece which is at least

1

/4”

(6.35mm) thicker than the timber for the joint,

under the top clamp, flush with the front of the

jig and well away from the edge guide.

Clamp it in position.

■ To set the left-hand edge guide, slide the first

box side (1) under the front clamp, keeping the

top edge flush underneath the template. Align

the left-hand offset line with the edge of a

finger (2).

Clamp the piece in this position (3).

-19-

Timber Widths

■ Any width of timber up to 300mm wide

can be comb jointed, however to

obtain an even looking symmetrical

comb joint where there is an extra

pin/socket, the timber must be

machined to a width shown in the

chart.

■ For timber that is not machined to the

recommended width, either the end

pin/sockets will need to be narrow or

an un-symmetrical comb will have to

be machined.

Loading...

Loading...