6

2.0 INSTALLATION

2.1 Orientation

The flow meter can be mounted in any orientation. However, for optimum

performance and ease of inspection, it is desirable to mount the flow meter in a

horizontal section of pipe. This ensures the rotating piston is not influenced by

gravity when at rest.

2.2 Meter location

The flow meter should be fitted upstream of any flow control or cut-off valve. This

prevents free discharge from the flow meter and minimises the risk of drainage

and air entrapment which may cause erroneous readings on start up.

The Multipulse positive displacement flow meter does not require any flow

conditioning, therefore straight runs of pipe before and after the flow meter are

not necessary.

The flow meter is not to be exposed to any form of hydraulic shock or over

speeding as this could damage the internals.

2.3 By-pass Installation

It is our recommendation the flow meter be installed in a by-pass section of pipe

with isolation valves to enable the flow meter to be isolated during pipeline

purging. If a by-pass is impractical, flush the pipe work to purge out foreign

matter such as rust, welding slag and sealing compound prior to installing the

flow meter or temporarily remove the piston, partition and centre bearing to allow

free passage of the foreign matter.

The by-pass configuration should also be used if the system is exposed to

periodic steam or air purging. ( See 5.0 Cleaning In-Situ )

2.4 Strainers

It is sound practice to locate a suitably sized strainer immediately upstream of

the flow meter. Recommended strainer mesh sizes are;

Model No. Mesh size Microns

MP015 100 150

MP025 / MP040 50 250

MP050 25 500

A range of strainers are available to suit both the Multipulse PD and Turbopulse

turbine meter range.

7

2.5 Commissioning

Immediately after installation or after long periods of shut down, the flow meter

must be slowly purged of air. This can be achieved by allowing the liquid to flow

through the flow meter at a slowly increasing rate until the air is released.

When metering liquids with a viscosity greater than that of water, the maximum

flow rate must be reduced to a level that will produce a pressure drop across the

flow meter of no more than 280 kPa ( 2.8 bar ).

The flow meter is now ready to put into service and will accurately measure all

liquids passing through it, provided it is not operated outside its specified limits.

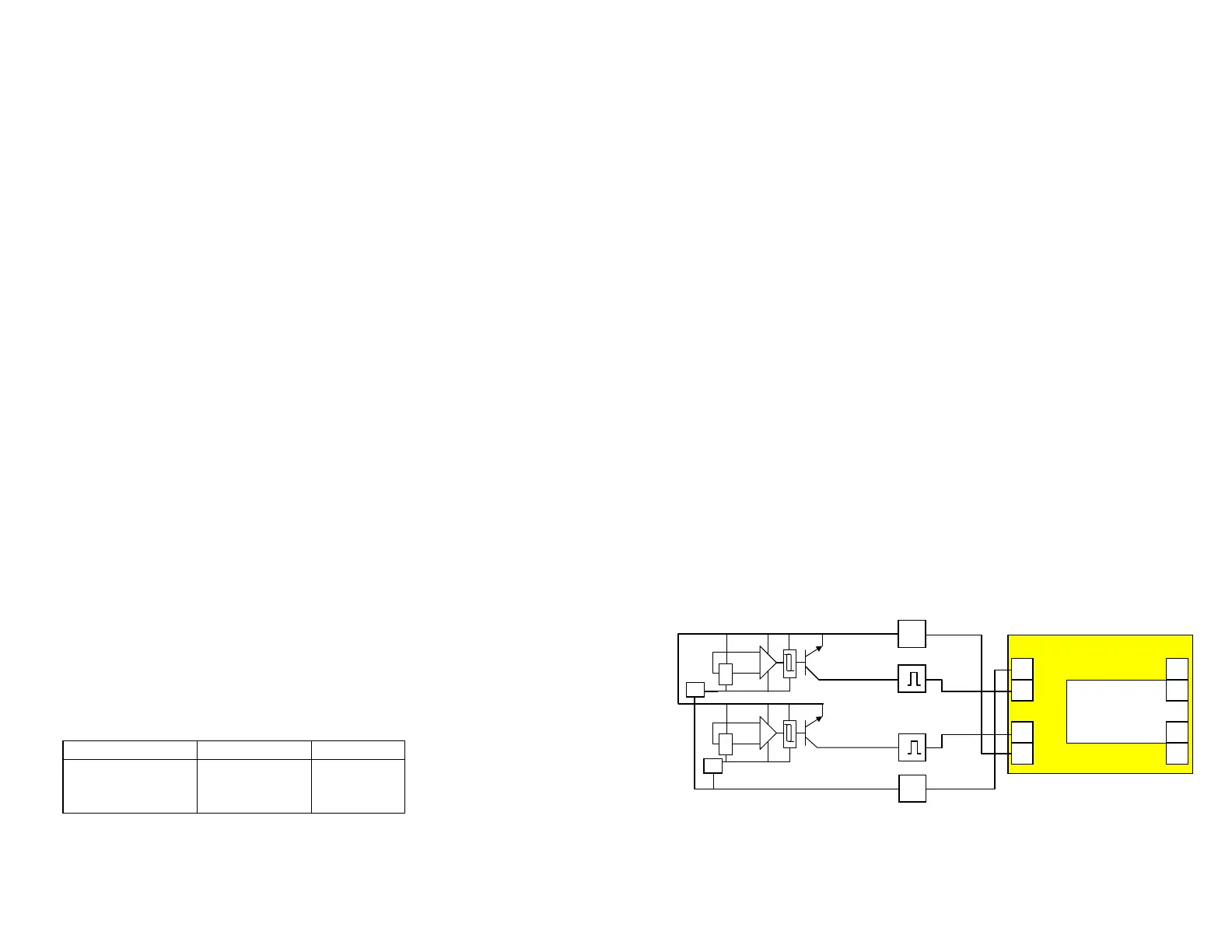

2.6 Reverse flow (bi-directional flow)

The flow meter is capable of accurately measuring flow in the reverse direction.

Meters fitted with the QP output option (quadrature pulse output) may be

interfaced with the Trimec Pulse Discriminator Module (PD1) to separate

forward & reverse flow output pulses for input to the appropriate totalising

registers or add and subtract counter input.

It is important to note that the Quadrature Pulse option has the same pulse

resolution (pulses/unit volume) as that of the reed switch for each size

Multipulse flowmeter.

Where reverse flow is not to be registered it is wise to install a check valve

upstream of the flow meter.

Flowmeter with QP outputs

PD1 Pulse Discriminator

-

+8~24Vdc

1

2

5

4

Output signals

Sig.1

Sig.2

-0V

+Vdc

10

9

5~24Vdc

Vdc

Output Signal 1

Ground

-0V

Reg

Output Signal 2

Reg

7

6

Loading...

Loading...