Page 8

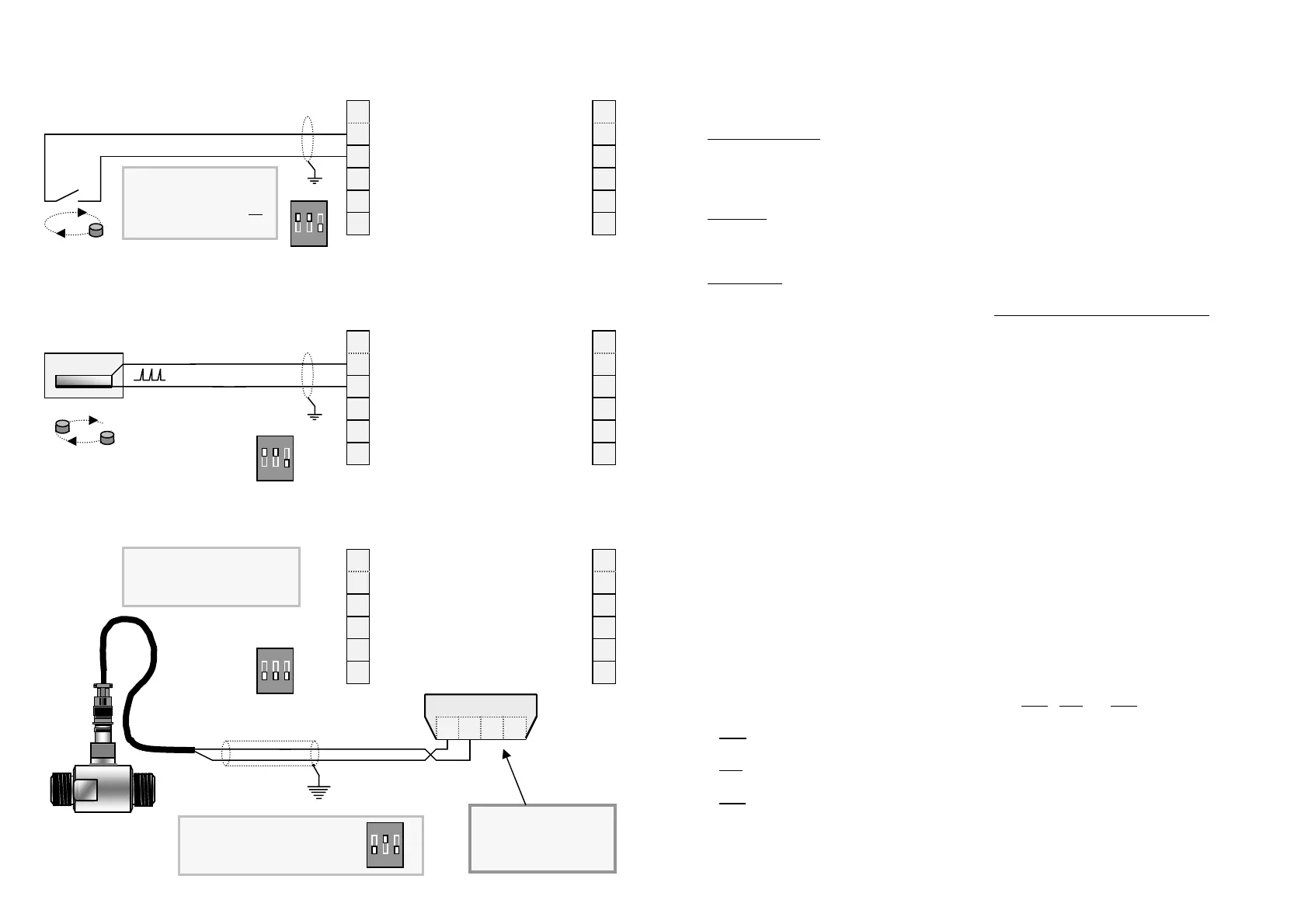

3.2 Flowmeter connections ( unpowered sensors )

Page 13

4.9 Presetting power levels

When the instrument is operated without external power being applied a special “Power

Mode ” program option will appear at level 12 of the programming chart. The three power

modes enable maximisation of the battery life according to operational requirements:

Ultra Power Save:

Typically selected if reading the register infrequently. Has the effect of

greatly extending the battery life.

In operation the display scrolls a prompt “PRESS ANY KEY ” when key

is pressed display wakes up for 4 minutes then returns to sleep mode*.

Standby :

Display becomes active whenever a key is pressed or product flows

through the flowmeter. Display returns to sleep mode* after 4 minutes of

no flow input or key actions, prompt then returns to “PRESS ANY KEY ”.

Continuous:

Display is active at all times resulting in reduced battery life.

* In sleep mode (and programming mode) flow is always continually totalised.

5. ADDITIONAL PROGRAM PARAMETERS ( model RT12 )

5.1 Analog Output

The loop powered 4 ~ 20mA output can be spanned anywhere within a flow range.

Testing the current loop can be done during programming when 4mA will output when at

programming level L14 and 20mA will output at programming level L15 (page 16).

5.2 Flow Alarms

Two flow alarm FET transistor relays may be programmed for Low & High flow alarms.

5.3 Flow Alarm Deadband

Alarms are NPN/PNP link selectable 100 milliamp max. An adjustable deadband (reset

differential) provides a trip buffer zone about the set point in order to overcome alarm

“chattering ” when the flow rate is fluctuating close to the alarm set point.

Deadband is entered as % of each set point value (refer to page 16 for an example).

5.4 Dual Flow Inputs

When externally powered the RT12 accepts inputs from two flowmeters (input A & input B), a

separate scaling factor is entered for the second flow input, the instrument is then

programmed for one of the dual input functions of A+B

, A-B or A÷B (ratio).

A+B

Both inputs are added and displayed as one for Rate & Totals.

A-B

Input B is subtracted from input A & the difference is displayed for both Rate & Totals.

A÷B

Totalises A & B separately & Rate is a function of A÷B to give instantaneous ratio.

Note : - When using A & B inputs the functions of Scaled Pulse output, Alarm set points

and the Analog output are relevant to resultant computation between A & B.

- The analog output of function A÷B can be used as an input for ratio control.

2. Voltage Pulse

S

N

0.1 ~ 2 vdc

Yellow

Green

6

5

4

3

2

7

8

9

10

11

High flow alarm

Low flow alarm

Scaled pulse output

Remote reset

+ 8~24VDC supply

- 4~20mA output

+ 4~20mA output

Flow input B

Flow input A

-0V Ground

121

-0V Ground + 8~24VDC supply

ON

1 2 3

1. Reed Switch

For reed switch inputs DIP

switch 1 (noise & bounce

filter) & 2 should be on

[ 200hz max. frequency ]

6

5

4

3

2

7

8

9

10

11

High flow alarm

Low flow alarm

Scaled pulse output

Remote reset

+ 8~24VDC supply

- 4~20mA output

+ 4~20mA output

Flow input B

Flow input A

-0V Ground

121

-0V Ground + 8~24VDC supply

ON

1 2 3

Default setting for input B if

input B is not being used.

ON

1 2 3

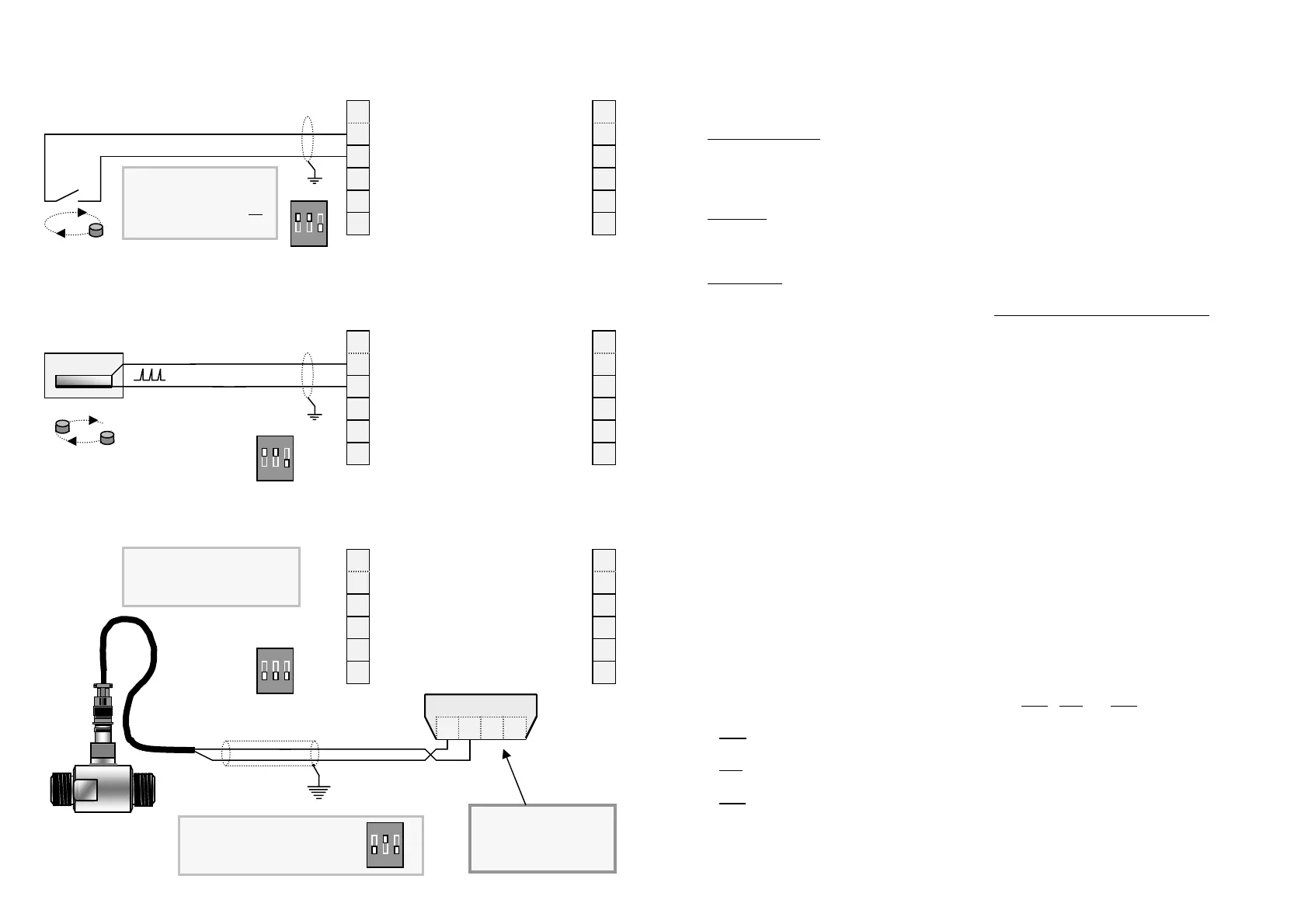

3. Coils

Typically turbine flowmeters

& coil style

paddle wheel flow sensors

Coil inputs A & B

A

A

B B

6

5

4

3

2

7

8

9

10

11

High flow alarm

Low flow alarm

Scaled pulse output

Remote reset

+ 8~24VDC supply

- 4~20mA output

+ 4~20mA output

Flow input B

Flow input A

-0V Ground

121

-0V Ground + 8~24VDC supply

ON

1 2 3

Twisted pair

Note: Coil input board

must be removed if

using flow inputs at

terminals 3 or 4

Ground screen

Loading...

Loading...