Page 14

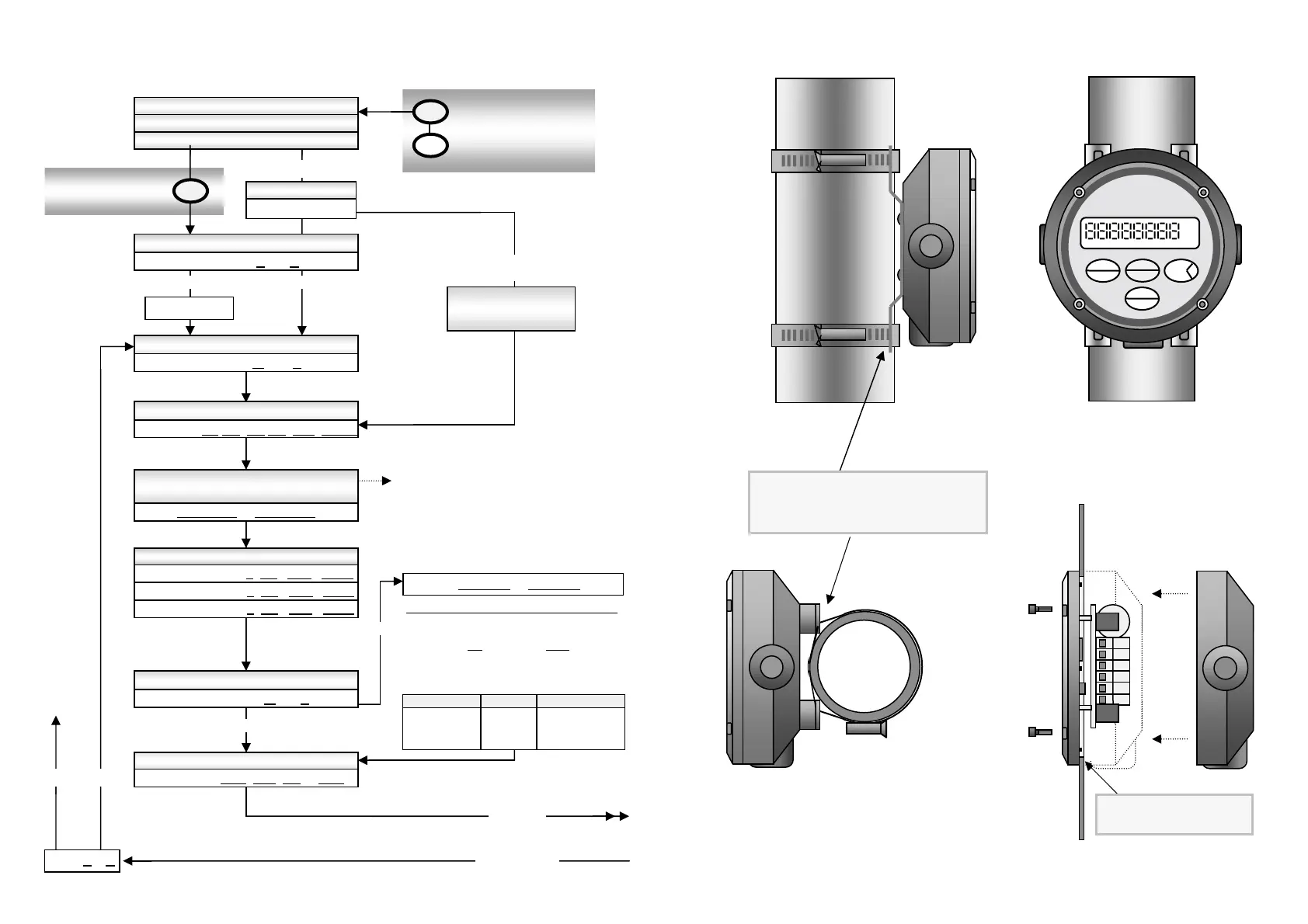

6. PROGRAMMING FLOW CHART

6.1 Program levels 1~7

Page 7

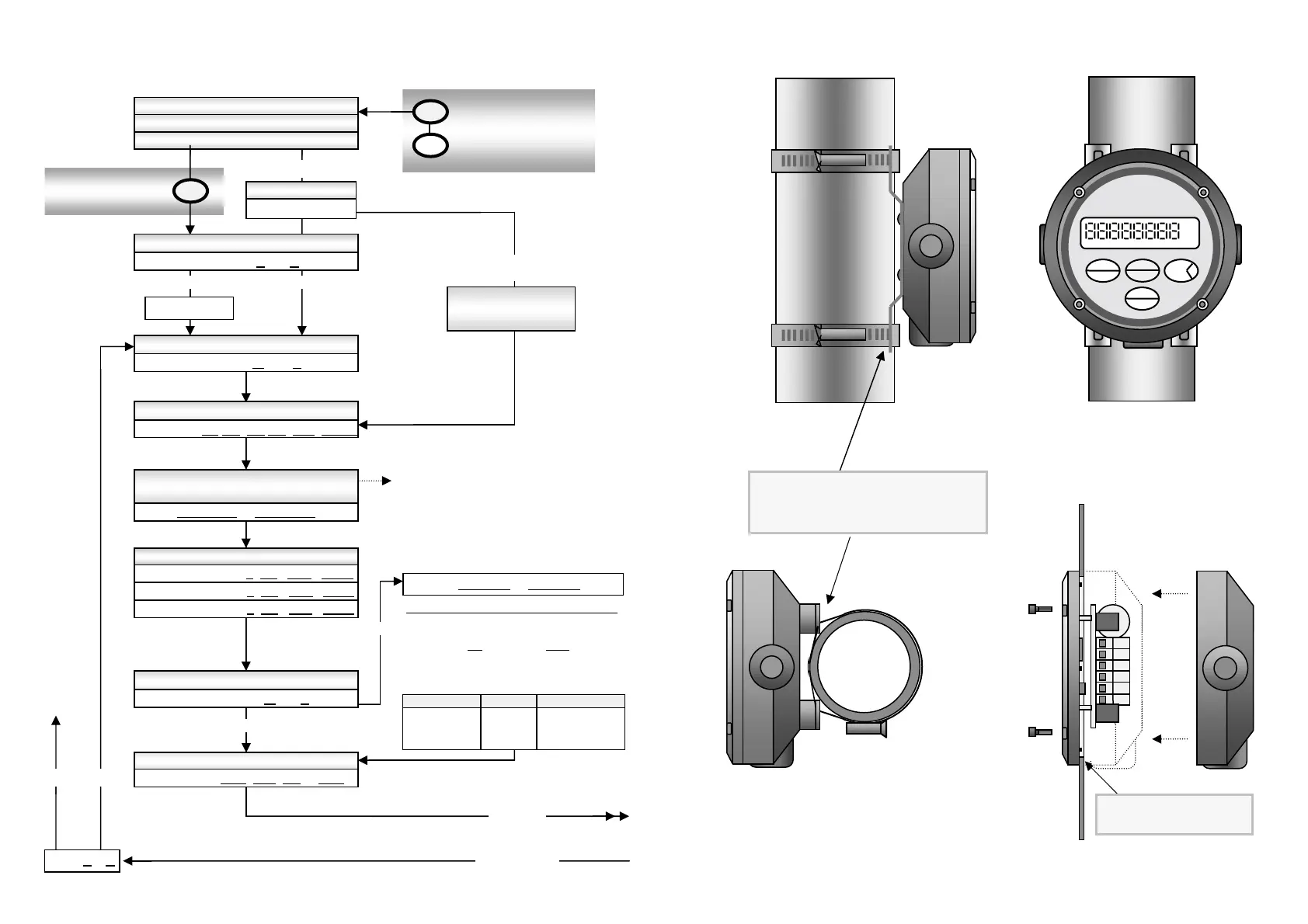

3.1 Mounting

press Prog. key to

advance through each

level of the program

* Vertical pipe mount

hold Program & Rate

keys for 5 seconds to

enter the program mode

Exit

program

mode

if PIN protected

INVALID PIN VIEW

EXISTING PROGRAM

DETAILS ONLY

if incorrect

PIN No. is entered

ENTER PIN

PIN _ _ _ _

L3 SET ENGINEERING UNITS

ENG UNIT Ltr gal m3 Ibs kgs (none)

L2 RESET ACCUM TOTAL Y / N

RESET Y - N

L5 SET DECIMAL POINTS

DPt TOTAL 0 0.0 0.00 0.000

DPt ACCUM TOTAL 0 0.0 0.00 0.000

DPt RATE 0 0.0 0.00 0.000

L1 CHANGE PIN No. Y / N

NU PIN Y - N

PIN _ _ _ _

YES NO

RT11 V1.9 HOLD 3 2 1

PROGRAM MODE ENTERED

TESTING DISPLAY 88888888

L4 ENTER NUMBER PULSES PER

Ltr m3 kg gal Ib (unit)

K0000.001 - K999999.9

YES

END Y - N

NO

L7 SET TIME BASE FOR RATE

Ltr gal etc / SEC MIN HR or DAY

L6 RATE CONVERSION Y / N

RATECON Y / N

R 0000.001 ~ 9999.999

NO

YES

PROG

RATE

K-factor (scale factor) is the number of

pulses per unit volume or unit mass

eg: 20.465 pulses / litre, gallon, kg etc.

WARNING on rate conversion factor (RCF)

This feature need only be programmed when

the total & rate engineering units are to be

different. eg: m3

for total and litres for rate

The conversion factor is the number needed

to convert to the required rate unit examples:

continued

program return

PROG

Total unit Rate unit Conversion facto

Cubic metres

US Barrels

Imp. gallons

1000.000

42.000

4.546

Litres /

USgal /

Litres /

* Ask for Pipe mount kit P/No. APM

comprising two brackets,

screws and worm drive clamps.

Panel mount

* Horizontal pipe mount

RATE TOTALISER

RATE

TOTAL

ACCUM

TOTAL

^

RESET

>

PROGRAM

ENTER

gal

RUN ACCUM. TOTAL STOP BAT LOW HIGH

Cut a 102mm (4 ”)

diameter hole in panel

Loading...

Loading...