Aquasensation AS2000X

13

RESISTANCE IS FELT, DO NOT FORCE THE

CONTROL FURTHER.

Note: The temperature control rotates less than

one complete turn (fig.22). DO NOT force it

beyond these limits.

To stop the water flow, switch off the electricity

supply at the isolating switch.

Check for leaks in the pipework and remedy

if necessary. If rear entry has been used then

seal around pipes with mastic to prevent the

possibility of water entering the wall cavity.

DO NOT use plaster as this could cause difficulty

if maintenance is required later.

Setup procedure

MAKE SURE THE ELECTRICITY TO THE UNIT IS

SWITCHED OFF.

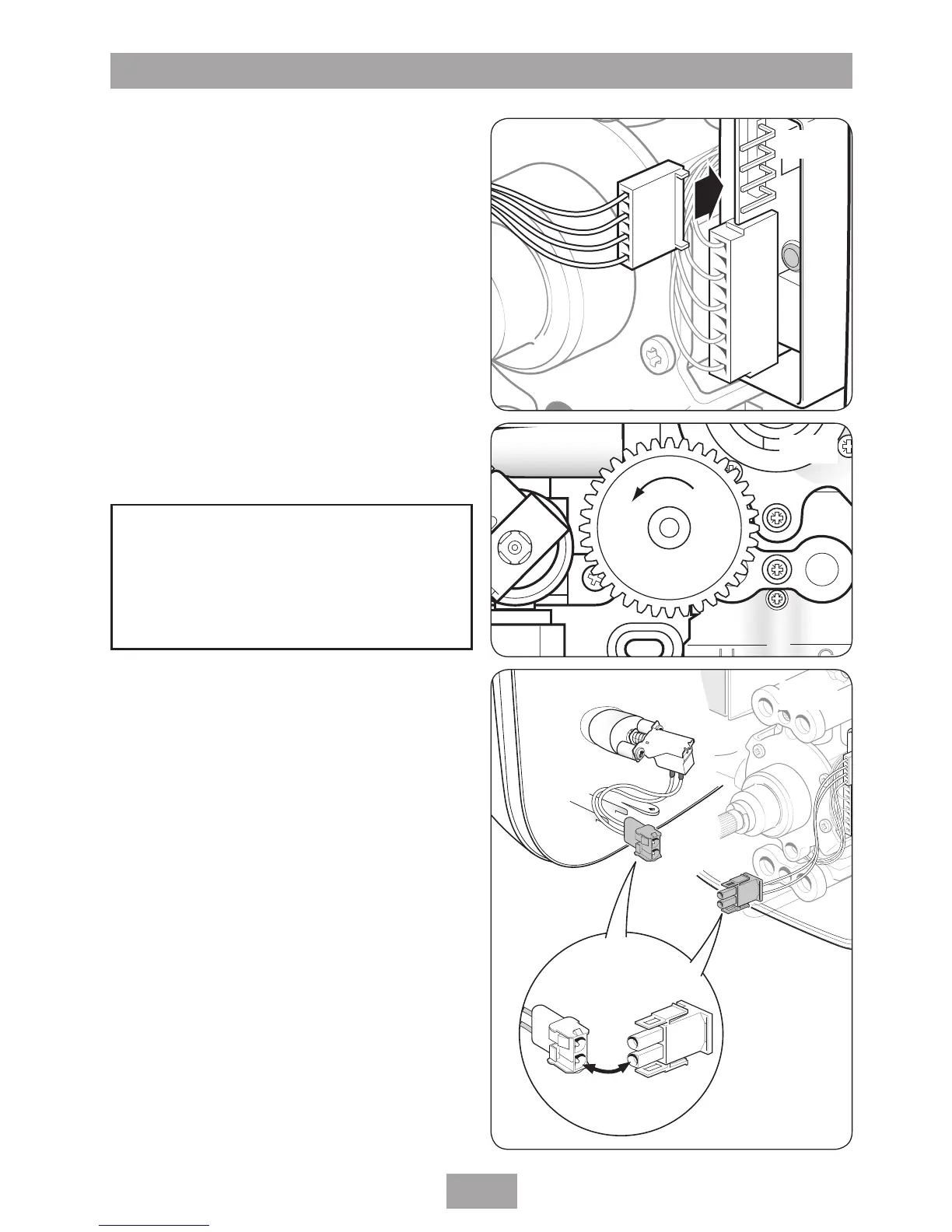

Pull off the temperature control. Remove the

commissioning link from the PCB (fig.23) and

store safely for future use.

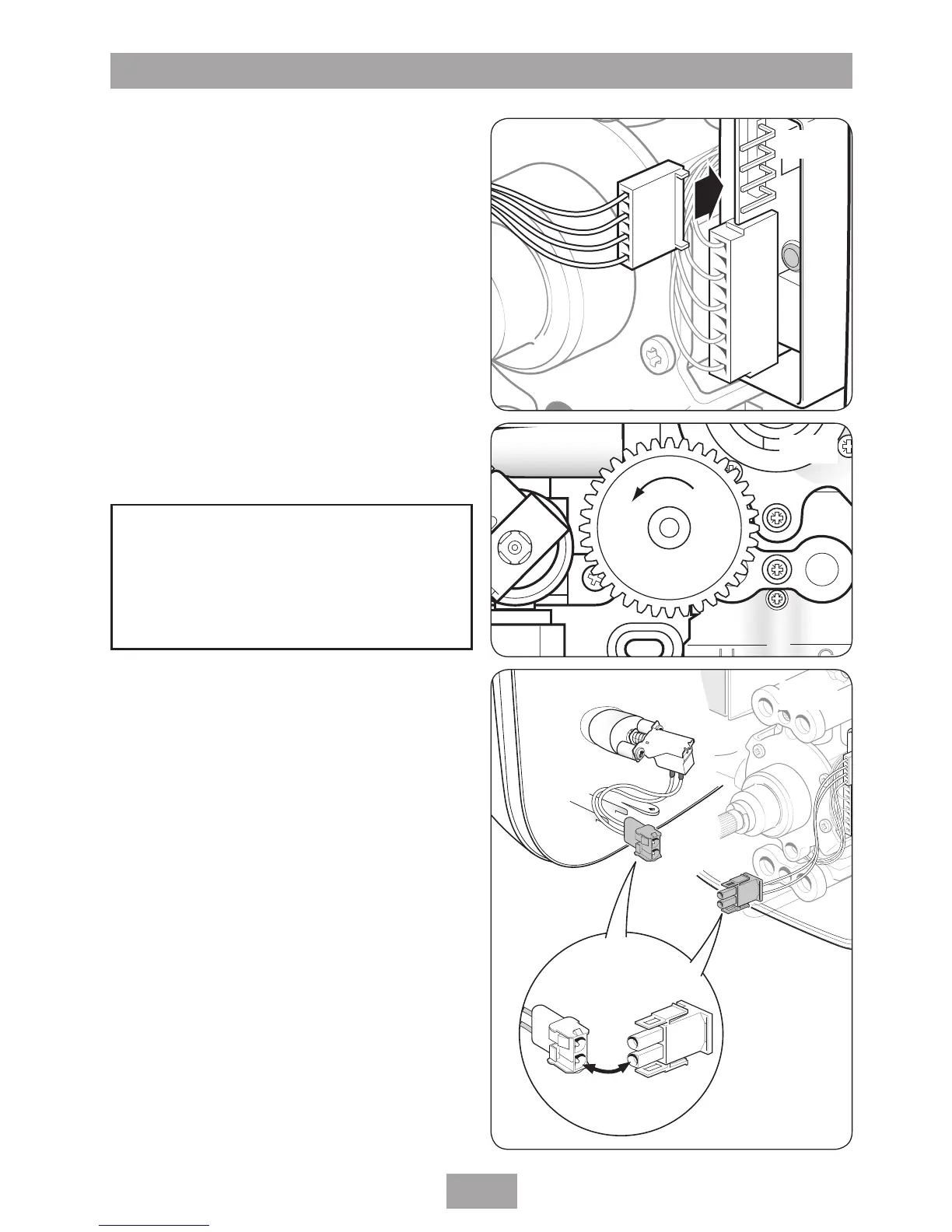

Inside the cover, attached to the flow control

potentiometer is a 4-wire lead. Fit the connector

on the end of this lead to the 4 pins on the PCB

(fig.24) – it can fit either way.

Make sure the potentiometer control is rotated

fully anti-clockwise (fig.25).

Replacing the cover

Offer the cover to the backplate unit. Inside

the cover, attached to the stop/start switch is

a two wire lead. The socket on the end of this

lead must connect to the plug attached to the

backplate unit (fig.26).

Fit the cover, making sure the connector is fitted

to the PCB and the wires are clear of obstructions.

Secure with the top and bottom fixing screws

(fig.8).

WARNING!

Once the unit has been commissioned,

turn off the electricity supply at

the mains before removing the

commissioning link.

Fig.24

Fig.25

Fig.26

Loading...

Loading...