Maintenance

Troubleshooting

12

The machine is not

running when turned

on.

The band is not

moving and the

motor is running.

The band is not

cutting in a straight

line.

The band is not

cutting or cuts slowly.

The band is not

cutting or cuts slowly.

Dust inside the

motor cover.

The machine is not

cutting 45° or 90°

angles.

The band cannot be

positioned

adequately in the

flywheels.

• No power supply.

• Defective power cord.

• The band tension knob is not tight.

• The band got loose from the flywheels.

• The saw band is broken.

• The direction band is broken .

• The support fence is not being used.

• The feeding rhythm is too fast.

• The band teeth are dull or damaged.

• The band guides are misadjusted.

• Teeth are dull.

• The band is mounted backwards.

• This is due to normal use.

• This is due to normal use.

• The table is not set into the right angles with

regards to the band.

• The band is dull or there was too much

pressure exercised in the work piece.

• The flywheels are crooked.

• The flywheel alignment knob has not been

adequately adjusted.

• The band is defective.

• Check the cord for wear and tear.

• Go to a Authorized Service

Center to repair.

• Turn off the motor and tighten the band tension

knob.

• Open the cabinets and check the band set up.

• Replace saw band.

• Replace band.

• Use the support fence.

• Feed the work piece slowly and with moderate and

constant pressure to prevent the band from bending.

• Replace band with a new one.

Adjust the band guides (see page 8).

• Replace the band (see page 11).

• Install the band correctly.

• Clean the machine regularly. Open the cabinets and

remove dust with a vacuum cleaner and a brush.

• Clean the ventilation slots in the motor with a

vacuum cleaner. Remove dust constantly to prevent it

gets into the cover.

• Adjust the table (see page 7).

• Replace the band or exercise lower pressure on the

work piece.

• Go to a Authorized Service

Center to repair.

• Adjust the knob (see page 11).

• Replace the band with a new one.

Problem Cause Solution

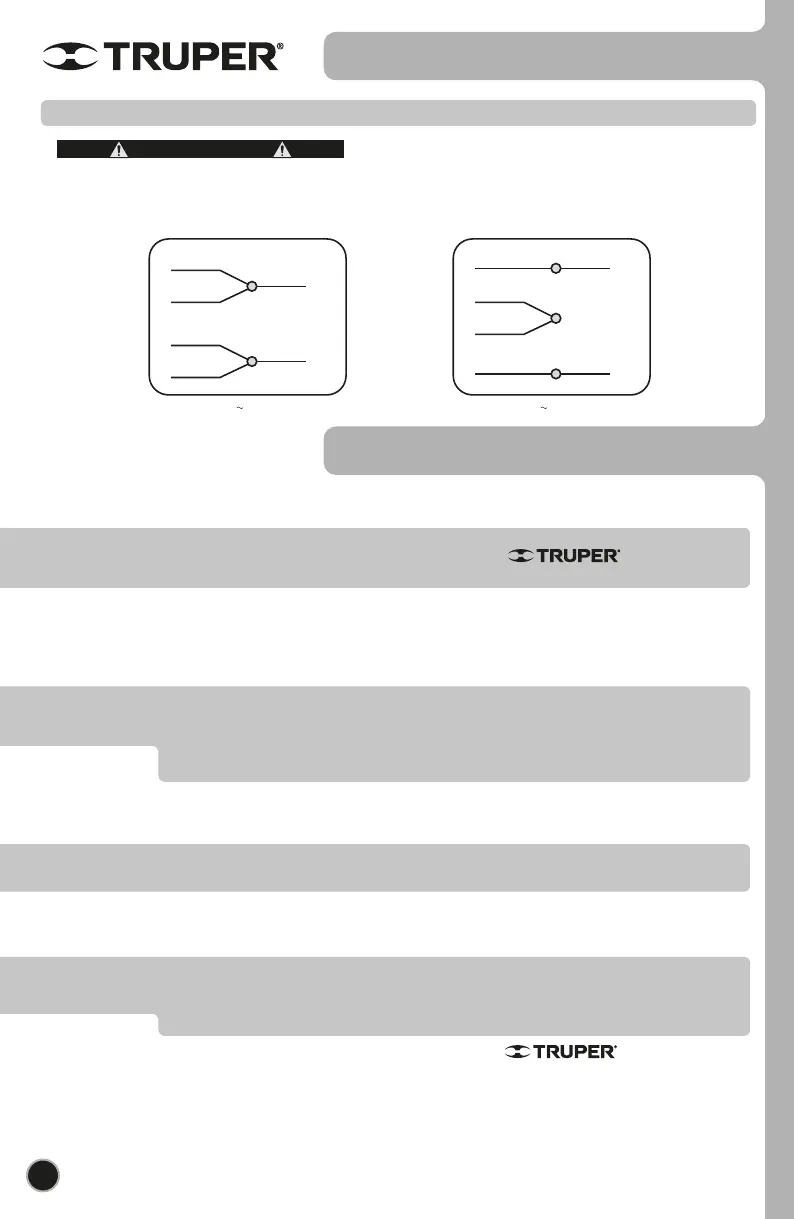

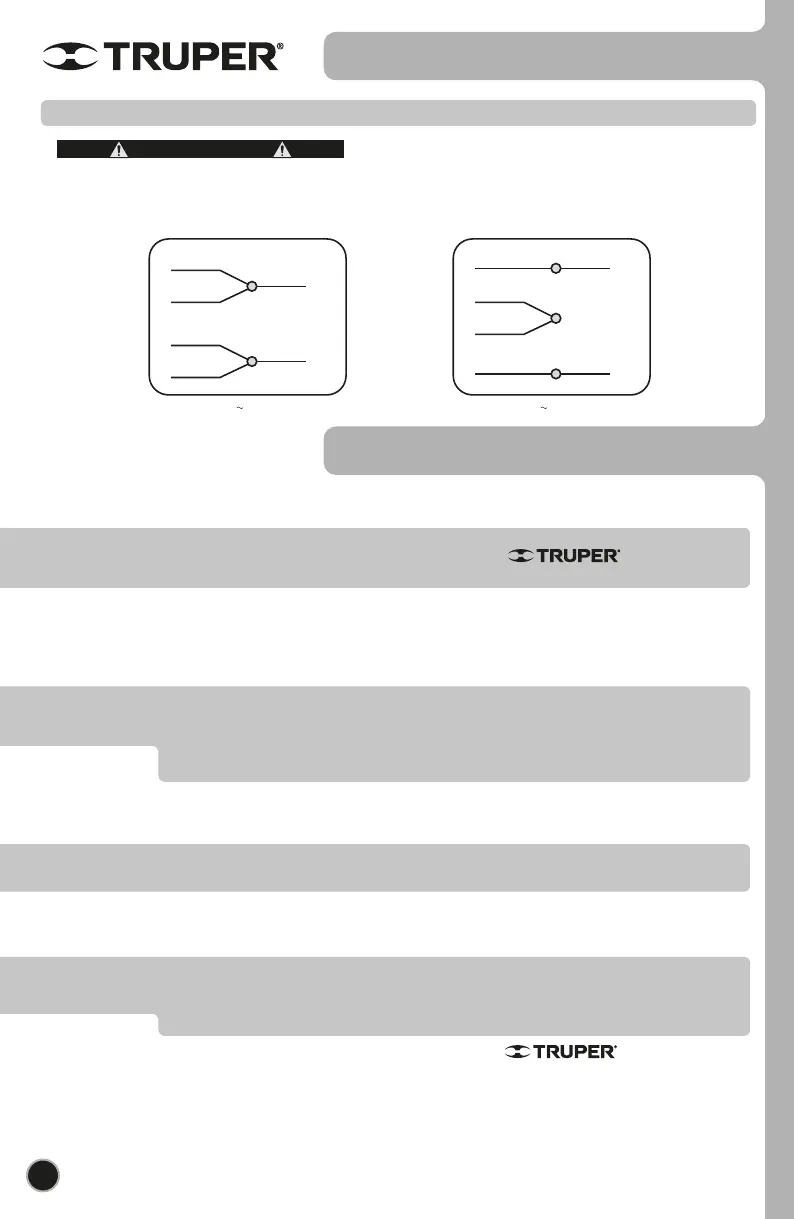

Electric connection diagram

BEFORE GAINING ACCESS TO TERMINALS ALL

FEEDING CIRCUITS SHALL BE DISCONNECTED.

WARNING

Below are the electrical diagrams to make the motor connections according to the supply voltage.

ENGLISH

120 V connection

BLACK

YELLOW

BLUE

WHITE

BLACK

WHITE

L1

L2

220 V connection

BLUE

YELLOW

WHITE

L2

BLACK

WHITE

BLACK

L1

Loading...

Loading...