14 PhenoMaster | Hardware Operating Instructions

Drinking and Feeding measurements

• The drinking and feeding sensors can be used with the dispensers supplied by TSE only - if

others are used, measuring errors will occur.

• (Re)assembly of rod drinking nipples

NOTICE - Dehydration hazard!

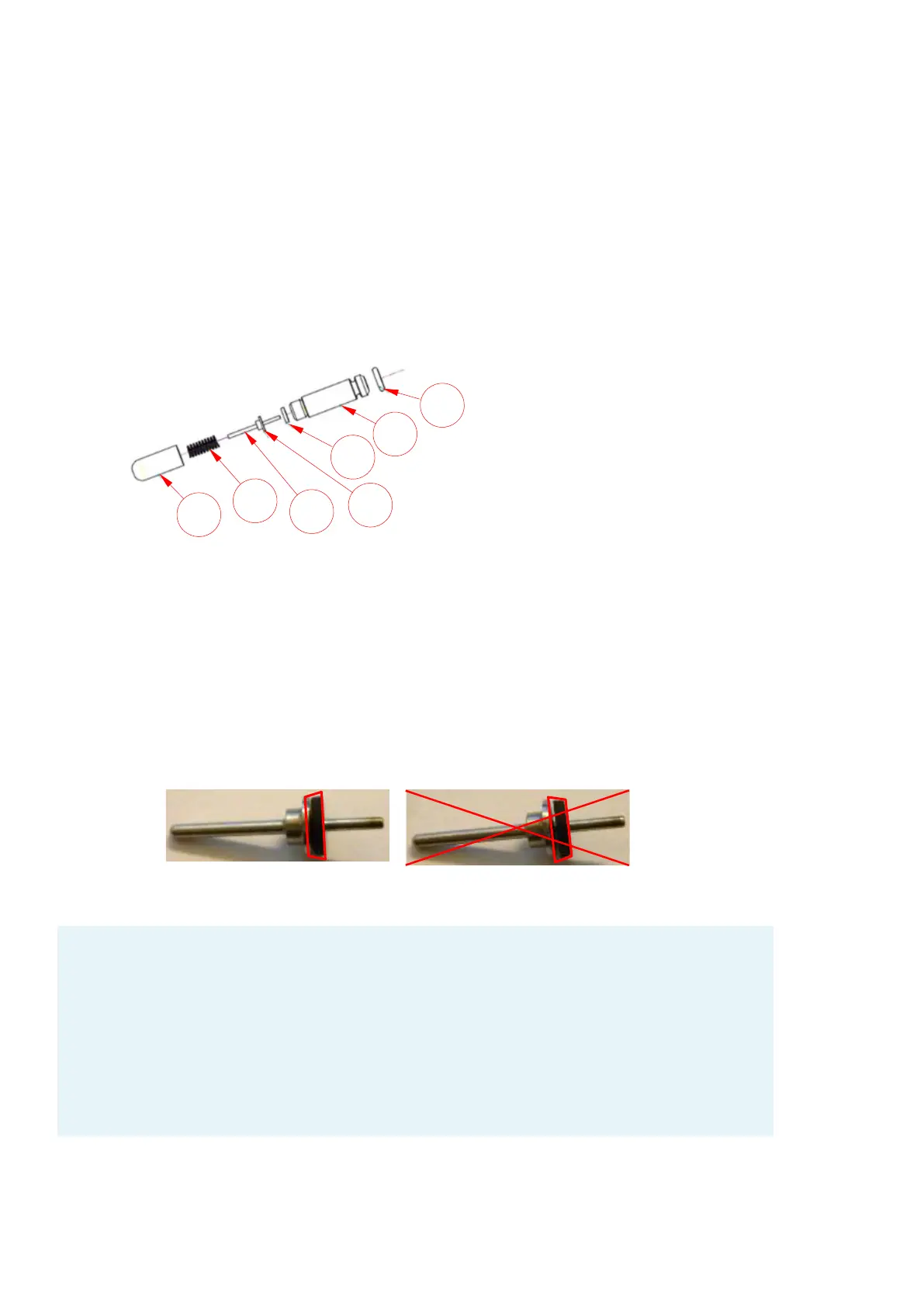

If the O-ring of the valve rod is positioned in the false orientation, flow through the opening of

the extension cap is always blocked and animals can die of thirst.

• Position O-ring onto the gasket so that its smaller base is orientated towards the gasket.

• After (re)assembly, always perform a test to ensure that liquid can flow throughout the nipple.

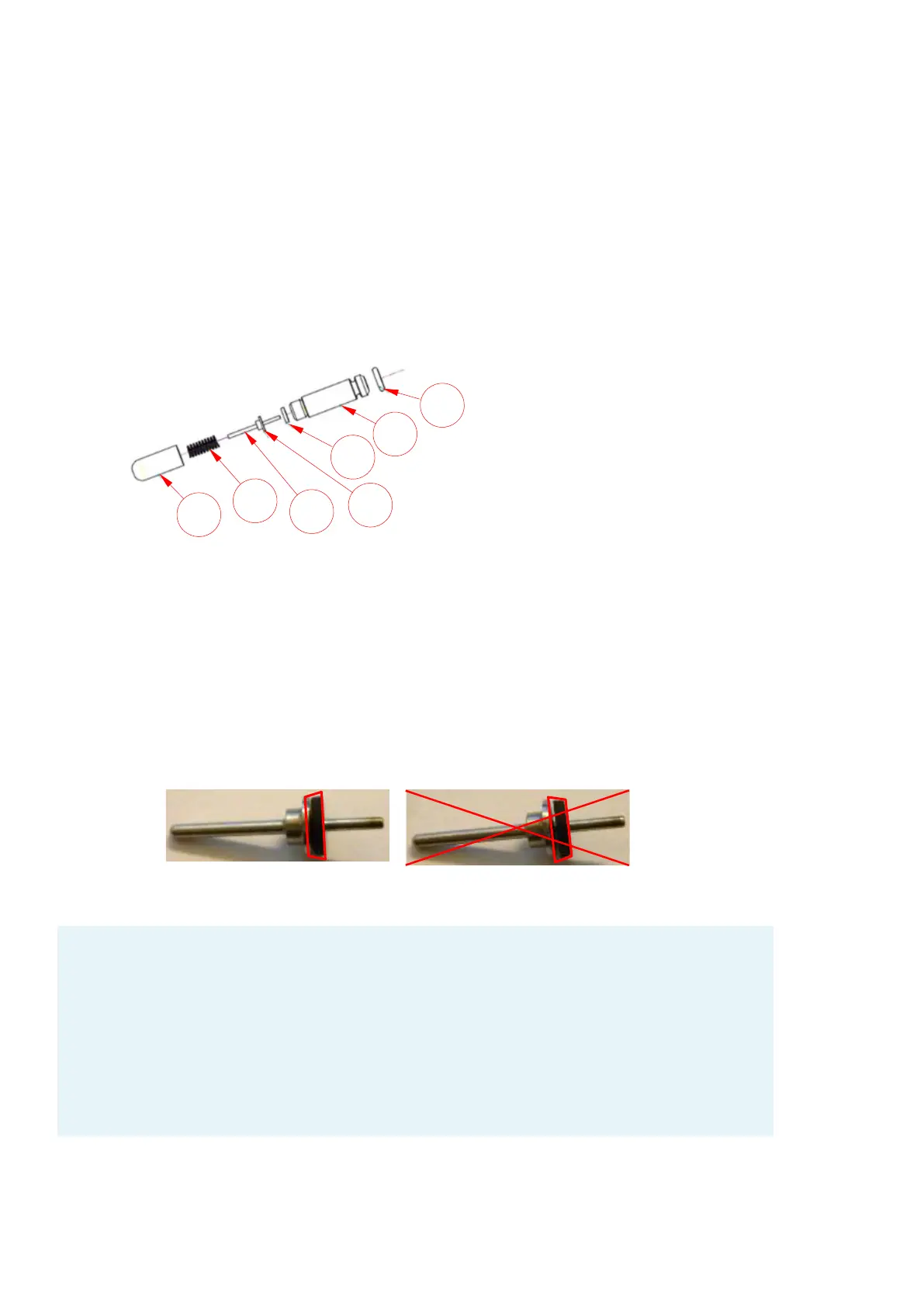

Fig. 3 Hardware layout - Rod nipple

1 Nipple receiver

2 O-ring, NBR (nipple receiver)

3 Valve rod

4 Gasket

5 O-ring, rubber (valve rod)

6 Pressure spring

7 Extension cap

o Position O-ring (valve rod) onto gasket (shorter end of valve rod). The smaller base of

the O-ring must be orientated towards the gasket, as otherwise flow through the

opening of the extension cap is always blocked and animals can die of thirst!

Fig. 4 Positioning of O-ring (valve rod)

How to test the operability, i.e. flowability, of the drinking nipple?

• Fill dispenser with water.

• If not already done, attach drinking cap including nipple.

• Suspend dispenser from sensor.

• Wait approx. 20s until water and air are in equilibrium.

• With a moistened finger, touch the tip of the nipple slightly (thereby moving the valve

rod to the side). It should be possible to "pull off" a drop. If not, a check for potential

sources and remedies, respectively, has to be made.

info@TSE-Systems.com www.TSE-Systems.com

Loading...

Loading...