Operating the Atomizer 4-3

5. To change the aerosol particle size, use a solution of different

concentration. Flush the Atomizer with about 25 cubic

centimeters of solvent and then refill the syringe with the new

solution. (A thorough cleaning—which means disassembling the

Atomizer—is usually unnecessary unless you change from a

high-solute concentration to a low-solute concentration.)

Prepare the Atomizer for operation as done in step 3.

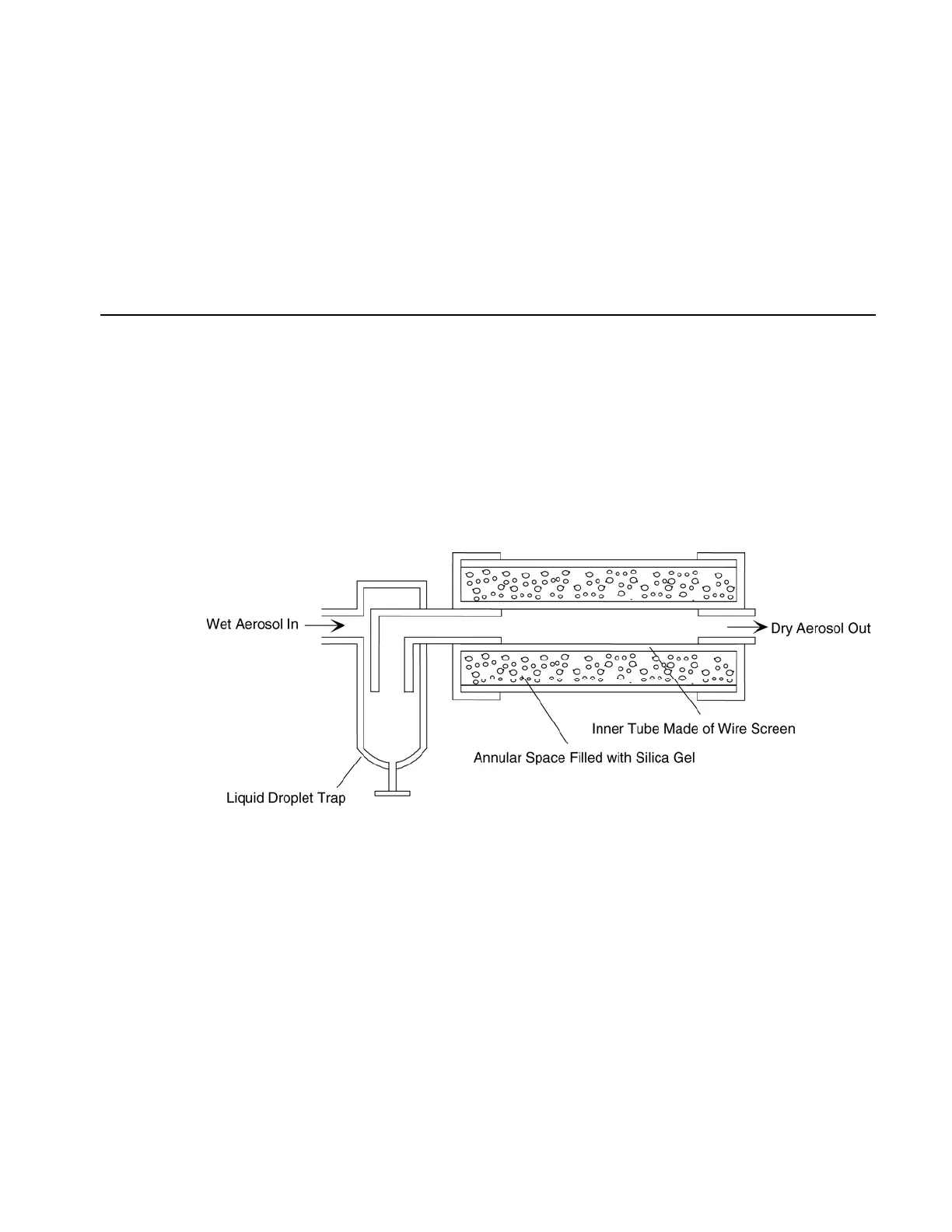

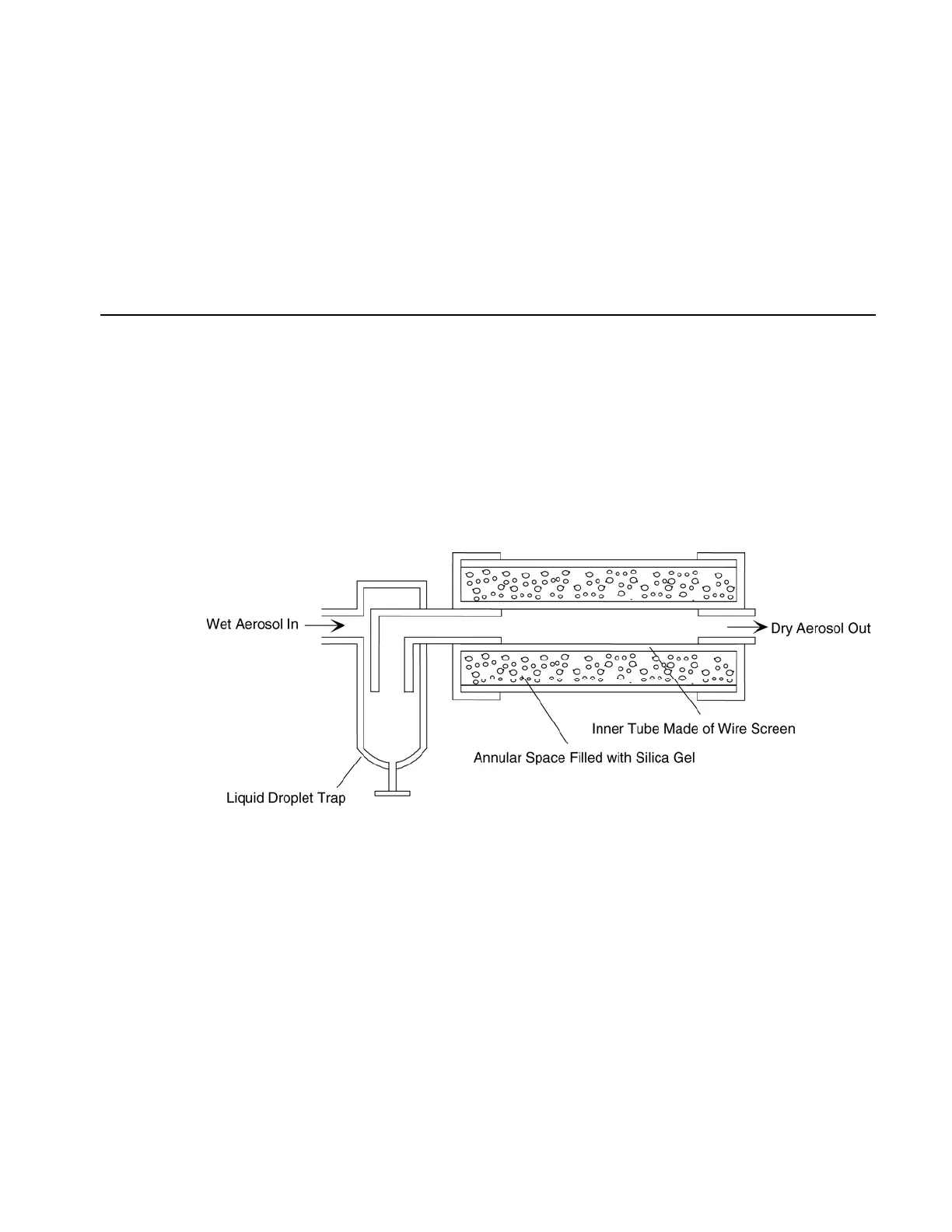

Drying the Aerosol

When generating aerosols from solid solute, the particles coming

out of the Atomizer are still wet and must be dried. Usually, the

aerosol is mixed with a large volume of dry, dilution air. Another

approach is to pass the aerosol through a diffusion dryer

(Figure 4-1). In this device, the aerosol passes through an inner

tube, made of wire screen. The silica gel surrounding the inner tube

maintains a dry atmosphere at the tube’s outer wall and the porous

wall absorbs water vapor as aerosol passes through.

Figure 4-1

Model 3062 Diffusion Dryer

Frequently check the condition of the silica gel around the inner

tube of the Atomizer to make sure the silica gel in the region next to

the screen tube is in active condition, that is, it looks blue. Install

the neutralizer immediately downstream of the diffusion dryer. The

dilution air used to dilute aerosol to the desired concentration must

be completely dry. Use a Swagelok-brand heat-exchanger tee to mix

the aerosol and the dilution air. By using such a tee, the aerosol

can be fed into the center of an annular, clean air stream, and thus

avoid excessive wall losses.

Loading...

Loading...