18

85876 & 85877 RevA

TURFCO T3100 APPLICATOR

The Sprayer

The sprayer has several components and controls you should be familiar with before operating the machine.

1. PUMP (See Figure 15) - The pump is located under the machine. The pump will start operating as soon as the

engine is started. The only control for the pump is the pump pressure control.

Take Care Of Your Pump.

When not spraying, the tanks should have at least 1 gallon of water in each tank to keep the pump

running cool.

While the pump is designed to be able to withstand being operated dry, running the pump

for extended periods with tanks empty could cause damage to the pump or lead to early failure.

2. PUMP PRESSURE CONTROL AND GAUGE (See Figure 14) - The Turfco T3100 Applicator has an adjustable

pressure spray system. The gray knob adjusts the pressure and the pressure is indicated on the gauge. The amount

of pressure in the system controls the amount of product being sprayed. Calibration, set-up and adjustment of

this control can only be done by licensed personnel. The pump pressure should never be adjusted by the

operatorintheeld.Consult the sprayer calibration adjustments in this manual. Watch the pressure gauge during

operation.Thegaugeshouldread40PSIwhenspraying.Note:Ifthetanksareempty,thegaugewillreadzero.

3. TANKS (See Figure 14) - The Turfco T3100 Applicator has two liquid tanks. Each Tank has a capacity of 9

gallons for a total of 18 gallons (68.1 liters). The tanks are connected to maintain an equal balance in both tanks.

The product being sprayed is equally pumped from both tanks and any bypass of product is equally returned to both

tanks.Theby-passowbacktothetanksistheagitationinthetankstomaintainproductmix.Liquidsolutionsare

all that are supposed to be used in these tanks. Wettable (soluble) powders may plug the system and should not

be used. PROPERLY MIX THE PRODUCT BEING SPRAYED

OUTSIDE OF THE TANKS BEFORE FILLING THE TANKS.

TO AVOID CONTAMINATION OF WATER SUPPLIES, NEVER

PLACE A HOSE DOWN IN THE TANK.

4. SPRAY CONTROLS (See Figure 14) - There are three spray

controls.

●Therightcontrolturnsonthefull(wide)spraynozzle.

●Thecentercontrolturnsonthespray(hand)gun.

●Theleftcontrolturnsonthetrimspraynozzle.

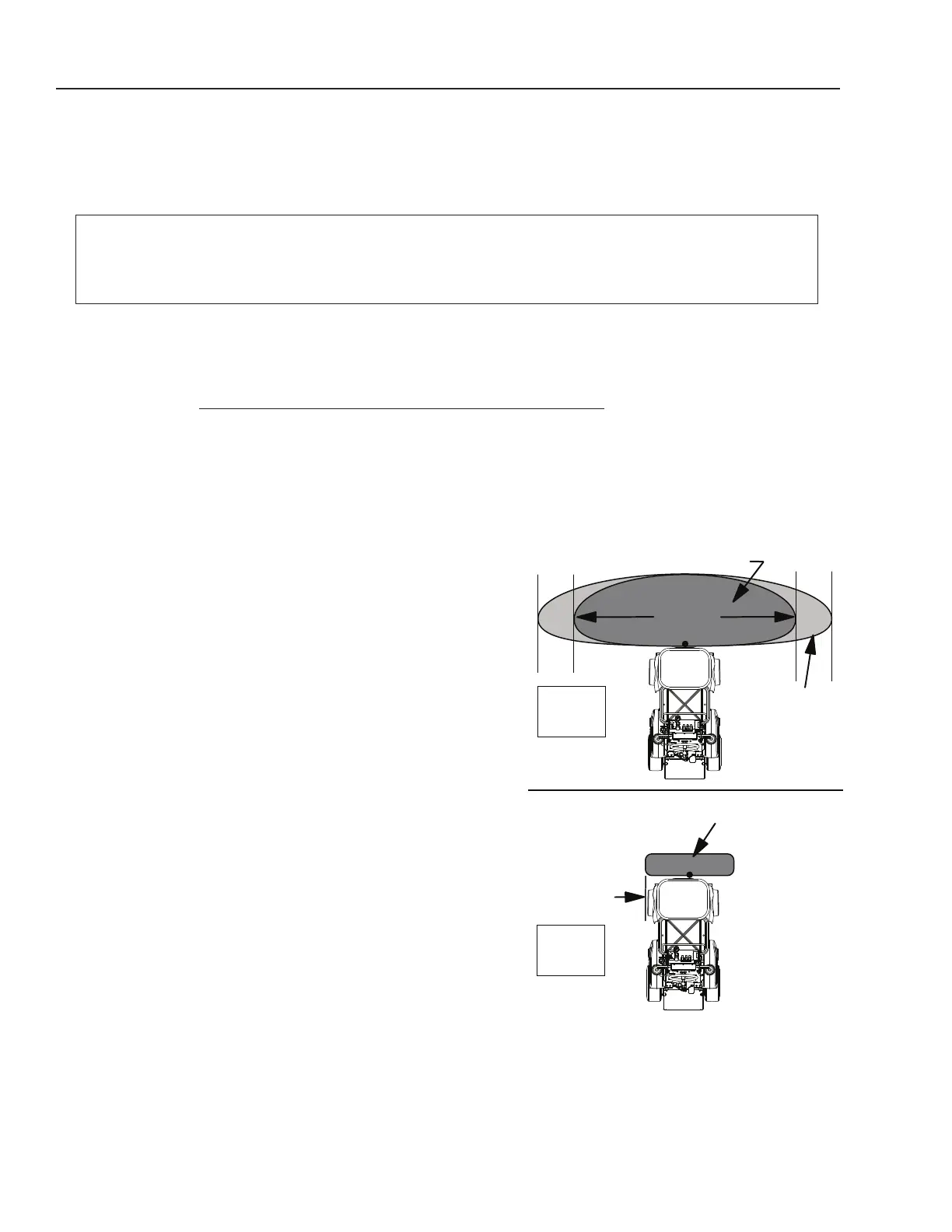

5. SPRAY NOZZLES (See Figures 13 and 15) - There are two

nozzles, one wide spray nozzle and one trim spray nozzle. The

Full and Trim nozzles will apply 1 quart per thousand sq. ft. at

40 psi (while spraying) and 5 mph (8.04 Km/h) when properly

calibrated.

See Page 32 for Sprayer Calibration

●Thefull(wide)spraynozzleislocatedabovethefrontcover

and is centered on the machine. This nozzle must be angled

15ºto25ºdegreesdowntowardstheturftoprovidethecorrect

spray pattern. The nozzle produces 9 foot wide “Effective Spray

Pattern” combined with a “Next Pass” overlap on both sides

resulting in a 12 foot wide spray pattern. Note that the 9 foot

turning radius of the machine will place you back in line with the

overlap “Next Pass” spray for your next pass.

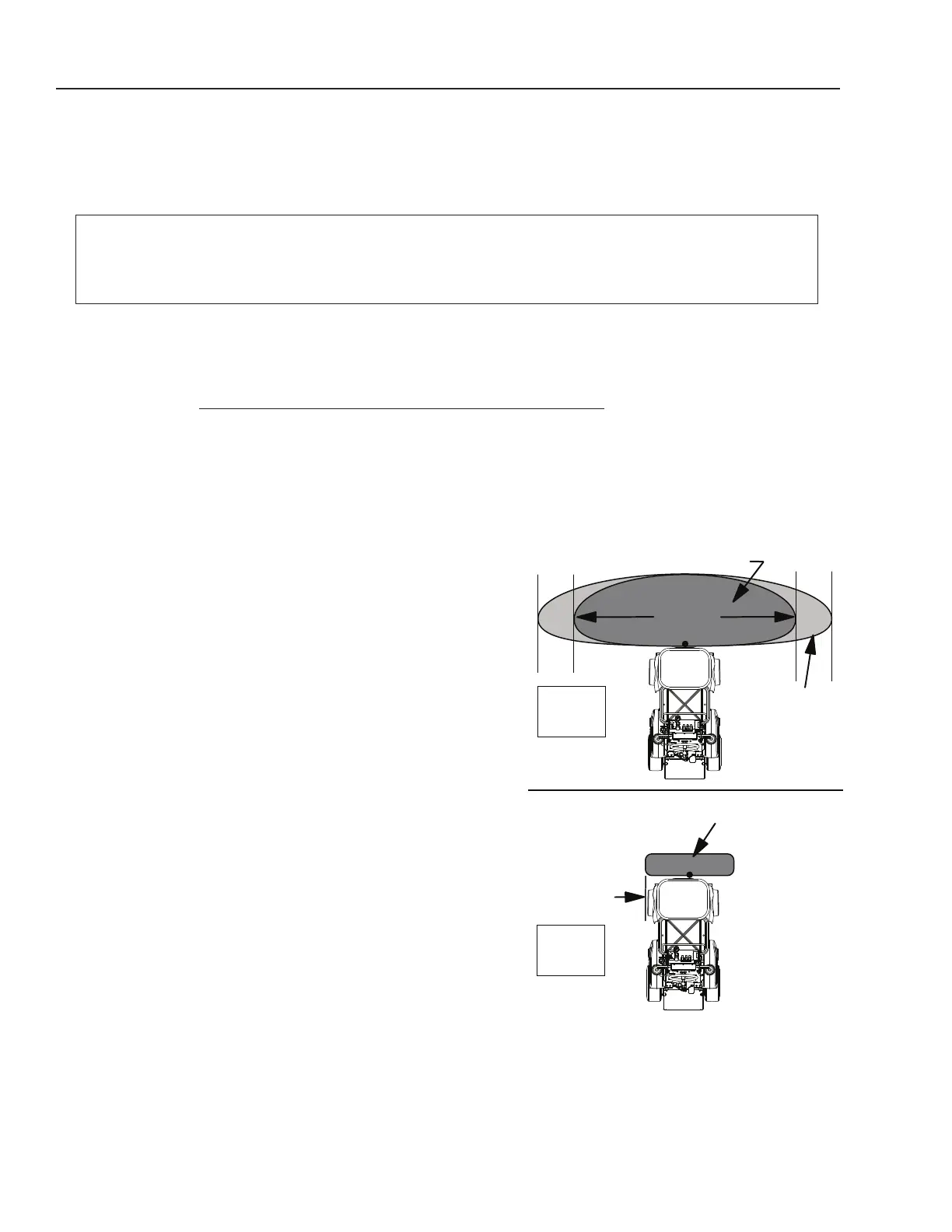

●Thetrimspraynozzleislocatedunderthefrontbumperandplacedofftotherightsideofthemachine.Thetrim

nozzle should be level with the ground. This nozzle produces a 3’ to 4’ foot wide “Effective Spray Pattern”. The left

edge of the spray pattern is 2” to 3” inches to the left edge of the left front tire for close trimming.

6. SPRAY GUN (See Figure 14) - The hand spray gun allows the operator to spot spray product in small areas.

When the center spray control is in the on position, the trigger on the gun allows the operator control the guns spray.

Usethespraygunowcontrolvalvetocontrol(limit)theamountofowtothespraygun.Allotherspraycontrols

should be off when using the spray gun.

TRIM

SPRAY

OP85872-19

EFFECTIVE SPRAY PATTERN

“NEXT PASS”

OVERLAP

SPRAY AREA

WIDE

SPRAY

EFFECTIVE SPRAY PATTERN

9' FEET

SPRAYS

2” TO 3”

INCHES

FROM LEFT

TIRE EDGE

OPERATION

Loading...

Loading...