35

85876 & 85877 RevA

TURFCO T3100 APPLICATOR

SERVICE AND MAINTENANCE

Storage

TO STORE THE T3100 OVER AN EXTENDED

PERIOD, perform a complete inspection. Refer any

needed service or repair to service level personnel.

● Completelycleanthehopperandspinnerwheel.

Use low pressure wash, DO NOT use high

pressure wash.

● Performacompletelubricationprocedure.

● Lubricate engine in accordance with the engine

manufacturers instruction.

● Lubricateallgreasettings.

● Emptytheenginefueltank

● Applyalmoflightmachineoiltothepivotpoints,

ball joints, steering components and engine to

control rust.

● Flush and drain the tanks. Leaving caustic

products in the system for storage could damage

the pump and hoses. (See Protection Against

Freeze Damage in the Winter Storage section)

● Toprotecttherubberandplasticparts,storethe

T3100 out of direct sunlight.

TO RETURN TO SERVICE AFTER EXTENDED

STORAGE, inspect the entire machine for any dam-

age that may have occurred during storage.

● Perform a complete lubrication procedure.

Lubricate engine in accordance with the engine

manufacturers instruction. Refer any needed

service or repair to service level personnel.

Winter Storage

Protection Against Freeze Damage

The pump, tanks and spray system must be protected

from freezing during storage. Use the following steps-

●Flushtheentirespraysystemwithcleanwater.Run

the pump until the tanks are completely empty and

water not longer sprays from the tips and the hand

held wand.

● Stop the engine and remove the cap from the

strainer. Allow any water to drain from the pump

and hoses. Replace the cap.

●Put1gallonofRVantifreezeineachtank.

TANKS MUST BE FLUSHED WITH WATER. DO

NOT PUT ANTIFREEZE IN WITH CHEMICAL

OR FERTILIZER AS A CHEMICAL REACTION

CAN OCCUR. CHEMICAL REACTIONS CAN

RELEASE HARMFUL AND TOXIC GASSES.

● Run the pump to circulate the antifreeze in the

system.

●Openeachvalveoneatatimeuntilantifreezesprays

from the tips. Use the hand held spray wand until

antifreeze sprays from the tip.

Do not spray out all of the RV antifreeze, allow

antifreeze to remain in strainer cap, pump,

controls and tanks.

DANGER

CLEANING

IMPORTANT!!

Keeping the machine clean and free of fertilizer

and chemical residue is critical to the life of

the machine. Always wash the machine until

it is clean and free of fertilizer everywhere.

Fertilizer left on the machine will ruin the

paint and cause corrosion. This will damage

the machine and be the cause of failures later.

● Wash the entire machine with a hose or a low

pressure washer.

● Avoidhighpressurewashingaroundbearings.

● WashouttheFertilizerhopper.

● Move the gate opening lever while washing to make

sure the gates are clean and free of chemicals. Use

a dry lubricant on the spreader linkages.

● Cleanthecarburetorgovernorspringsandlinkages

weekly. Refer to Lubrication Section in this Manual.

● Sparingly apply light machine oil to control rust.

Refer to Lubrication Section in this Manual.

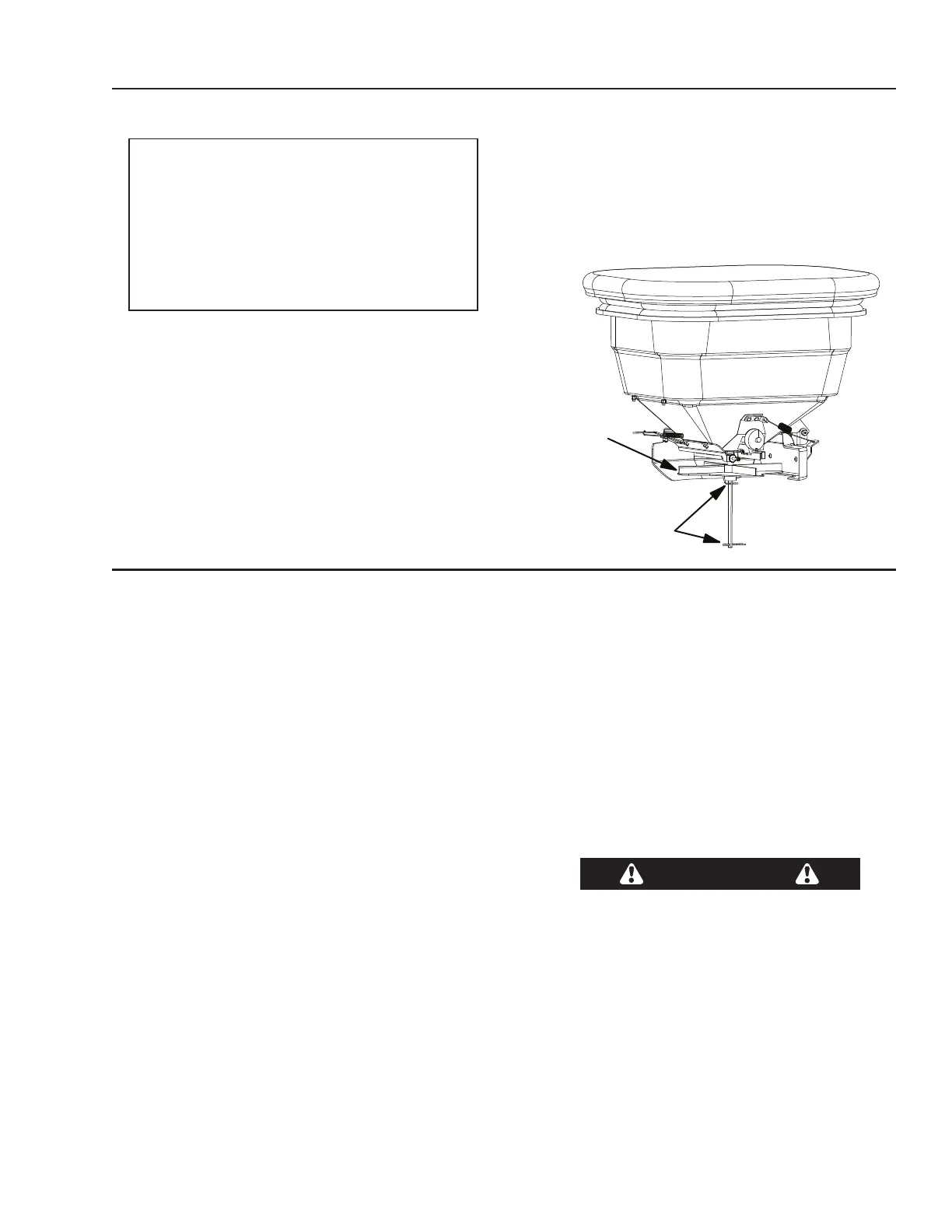

REMOVAL OF THE SPINNER WHEEL (See Figure

25) - The spinner wheel can be removed to aid in

inspection and cleaning. First remove two spinner

wheel pull pins. One from under the spinner and

one on the bottom of the spinner shaft. Then pull the

spinner shaft up and through the bottom of the fertilizer

hopper. To replace the spinner shaft and spinner just

do the reverse and replace the front cover.

SV85876-11RevA

WHEEL

FIGURE 25

SPINNER

WHEEL AND

SPINNER SHAFT

Loading...

Loading...