22

09

Troubleshooting

Manual 1808 Rev B p/n 001808 0000

When the pump is operating without gas ballast,

a sharp clicking noise generally indicates proper

valve closing. To gain access to the valves, drain

the oil and remove the cylinder cover. Remove the

screws from the hold-down plate and the valve can

then be removed. Check each valve by lifting the

disc, and check the surfaces between the disc and

seat for foreign matter, which may have lodged

there. Release the disc and a rm pressure should

close the valve, and the two parts should mate so

as to form a seal between them.

Check for guide wear by moving the disc laterally.

There should be little play at any valve lift position.

No burrs can be tolerated. The valve can be

disassembled for cleaning if necessary. However,

assembly must be done with the six springs

arranged in pairs with each pair positioned 120°

from the other two pairs, the spring tongues

facing the stop, and the free end facing the disc.

When cleaning is complete, reassemble the

pump, ll with oil, and test per Checking Pump

Performance on page 19.

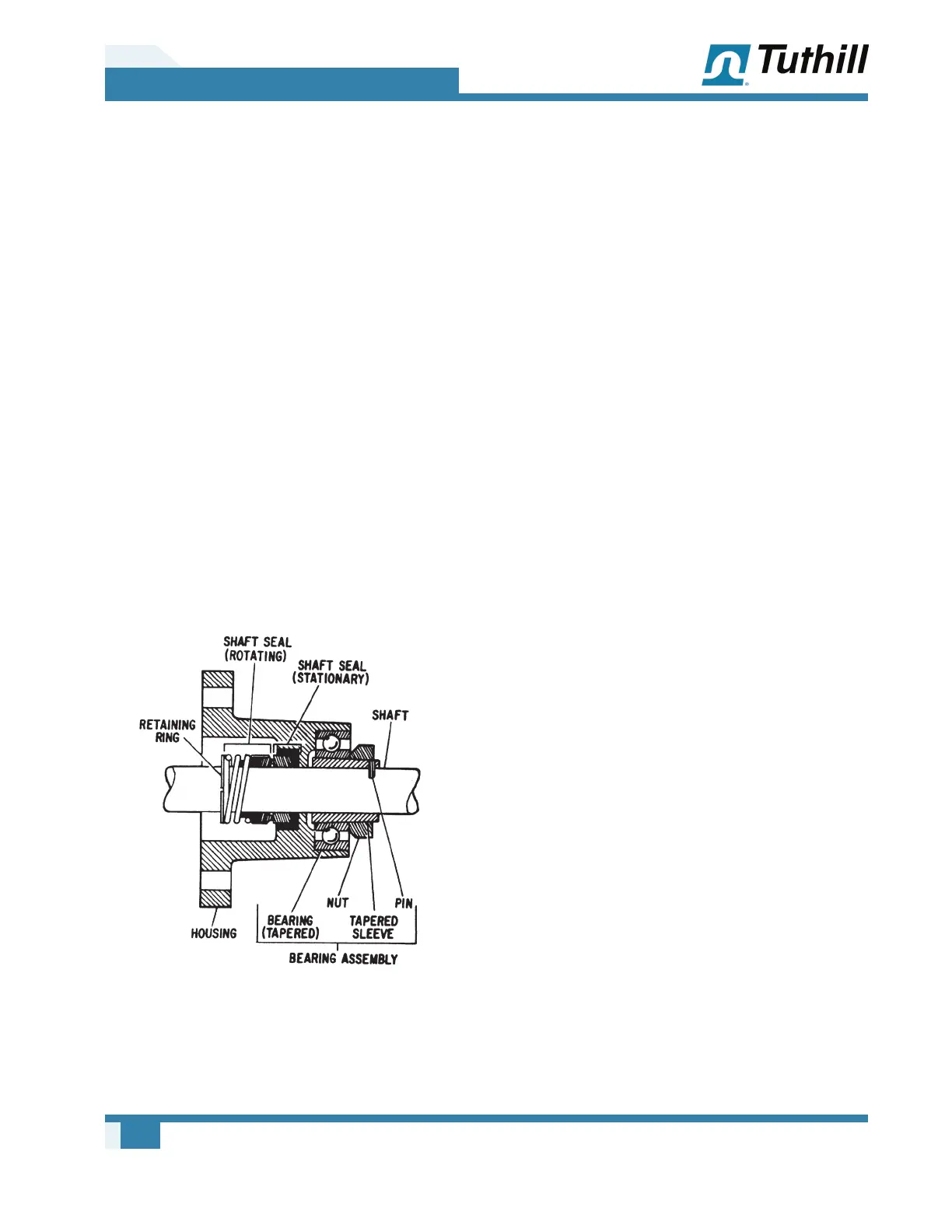

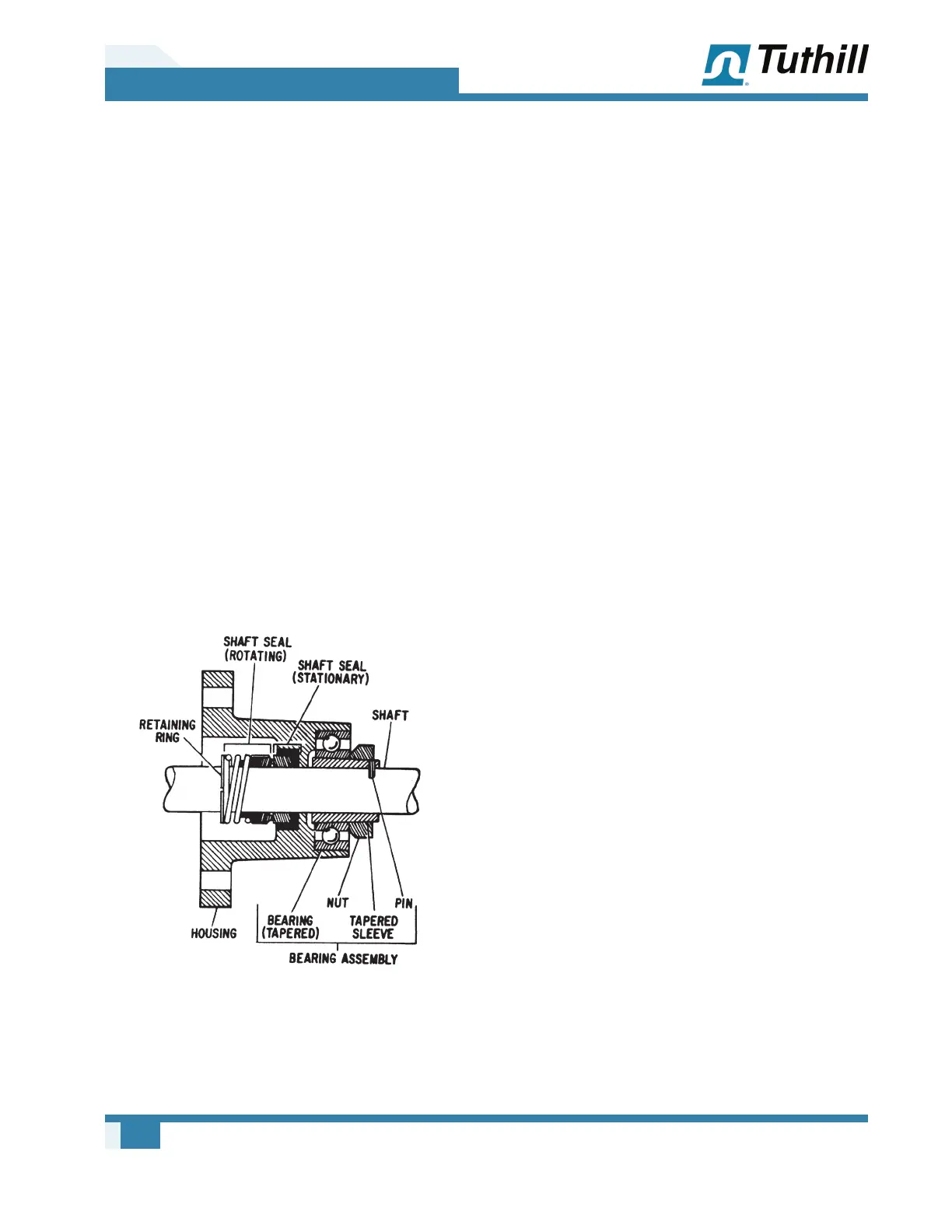

SHAFT SEAL

Figure 9-2 – Shaft Seal

Under normal conditions, the shaft seal shown

in Figure 9-2 on page 22 has a long, trouble-

free life. It may become worn or scratched on the

sealing surfaces by contaminated oil or it may be

damaged by overheating. Proceed as follows to

inspect or replace the seal:

1. Rest the pump on the closed head to prevent

the oil from draining out. Use blocks to prevent

the oil line from supporting the pump weight.

2. Remove the belt guard, belts, sheave, and

drive key from the pump.

3. Remove the bearing assembly by unscrewing

the locking nut. Lift the dowel pin out of the

shaft from the slot in the bearing sleeve. Tap

the sleeve to break the bond between the

sleeve and bearing. Remove four screws from

the housing and remove the housing from the

shaft. The ceramic (non-rotating) portion of

the seal will remain in the housing, and the

boot with the carbon ring (rotating) portion will

remain on the shaft. The bearing will remain in

the housing.

4. Inspect the ceramic portion in the housing

for signs of trouble such as a cracked seat or

deterioration of the elastomer seal between the

seat and the housing. Check that the rotating

portion of the carbon washer is not cracked

and that the face is smooth. The boot should

t rmly to the shaft and will bond to the shaft

when it has been run for a few hours. Do

not break this bond unless it is necessary to

replace the rotating part of the seal.

5. When replacing the shaft seal, clean the shaft

and housing areas where the seal was located,

and lubricate the seal, housing, and shaft with

grease. Press the non-rotating part of the seal

into the housing and slide the rotating part

onto the shaft. Be careful when sliding the seal

over the shaft that the keyway does not cut the

boot. Reassemble.

Loading...

Loading...