Care and

Maintenance

The Series TY-FRB, 5.6 K-factor Up-

right and Pendent Intermediate Lev-

el Sprinklers must be maintained

and serviced in accordance with this

section:

Before closing a fire protection sys-

tem main control valve for mainte-

nance work on the fire protection sys-

tem that it controls, permission to shut

down the affected fire protection sys-

tem must be obtained from the prop-

er authorities and all personnel who

may be affected by this action must

be notified.

Sprinklers that are found to be leaking

or exhibiting visible signs of corrosion

must be replaced.

Automatic sprinklers must never

be painted, plated, coated or other-

wise altered after leaving the factory.

Modified sprinklers must be replaced.

Sprinklers that have been exposed to

corrosive products of combustion, but

have not operated, should be replaced

if they cannot be completely cleaned

by wiping the sprinkler with a cloth or

by brushing it with a soft bristle brush.

Care must be exercised to avoid dam-

age to the sprinklers -before, during,

and after installation. Sprinklers dam-

aged by dropping, striking, wrench

twist/slippage, or the like, must be

replaced. Also, replace any sprinkler

that has a cracked bulb or that has

lost liquid from its bulb. (Ref. Installa-

tion Section).

The owner is responsible for the in-

spection, testing, and maintenance

of their fire protection system and de-

vices in compliance with this docu-

ment, as well as with the applicable

standards of the National Fire Protec-

tion Association (e.g., NFPA 25), in ad-

dition to the standards of any other

authorities having jurisdiction. The in-

stalling contractor or sprinkler manu-

facturer should be contacted relative

to any questions.

It is recommended that automatic

sprinkler systems be inspected, test-

ed, and maintained by a qualified In-

spection Service in accordance with

local requirements and/or national

code.

Ordering

Procedure

Contact your local distributor for avail-

ability. When placing an order, indi-

cate the full product name and Part

Numbers (P/N).

Series TY-FRB Intermediate Sprin-

klers are comprised of separately or-

dered components: Sprinkler, Guard,

and/or Shield.

Upright Sprinkler Assemblies with

NPT Thread Connections

Specify: Series TY-FRB Upright Inter-

mediate Level Sprinkler, K=5.6, (spec-

ify SIN), Quick Response, (specify)

temperature rating, (specify) finish,

P/N (specify from Table B)

Pendent Sprinkler Assemblies with

NPT Thread Connections

Specify: Series TY-FRB Pendent

Sprinkler, K=5.6, (specify SIN), Quick

Response, (specify) temperature rat-

ing, (specify) finish, P/N (specify from

Table B ).

Model G1/S1 Guard with Shield

Specify: Model G1/S1 Sprinkler Guard

with Shield, (specify) finish, P/N

(specify).

Red Painted .........P/N 56-938-1-066

Zinc Chromate . . . . . . . P/N 56-938-9-066

Model G1 Sprinkler Guard

Specify: Model G1 Sprinkler Guard,

(specify) finish, P/N (specify).

Red Painted .........P/N 56 -938-1-001

Zinc Chromate . . . . . . . P/N 56-938-9-001

Model S2 Pendent Shield with

O-Ring

Specify: Model S2 Pendent Shield

with O-Ring, 1/2” NPT, Series TY-

FRB Pendent Sprinklers, P/N

56-070-9-332.

Sprinkler Wrench

Specify: W-Type 6 Sprinkler Wrench,

P/N 56-000-6-387.

Additional* Guard Installation Tools

Specify: Guard Installation Tool for

Model G1 Sprinkler Guards, P/N

56-000-8-597.

*

The Guard Installation Tool is included with

orders in original carton quantities.

TFP357

Page 5 of 6

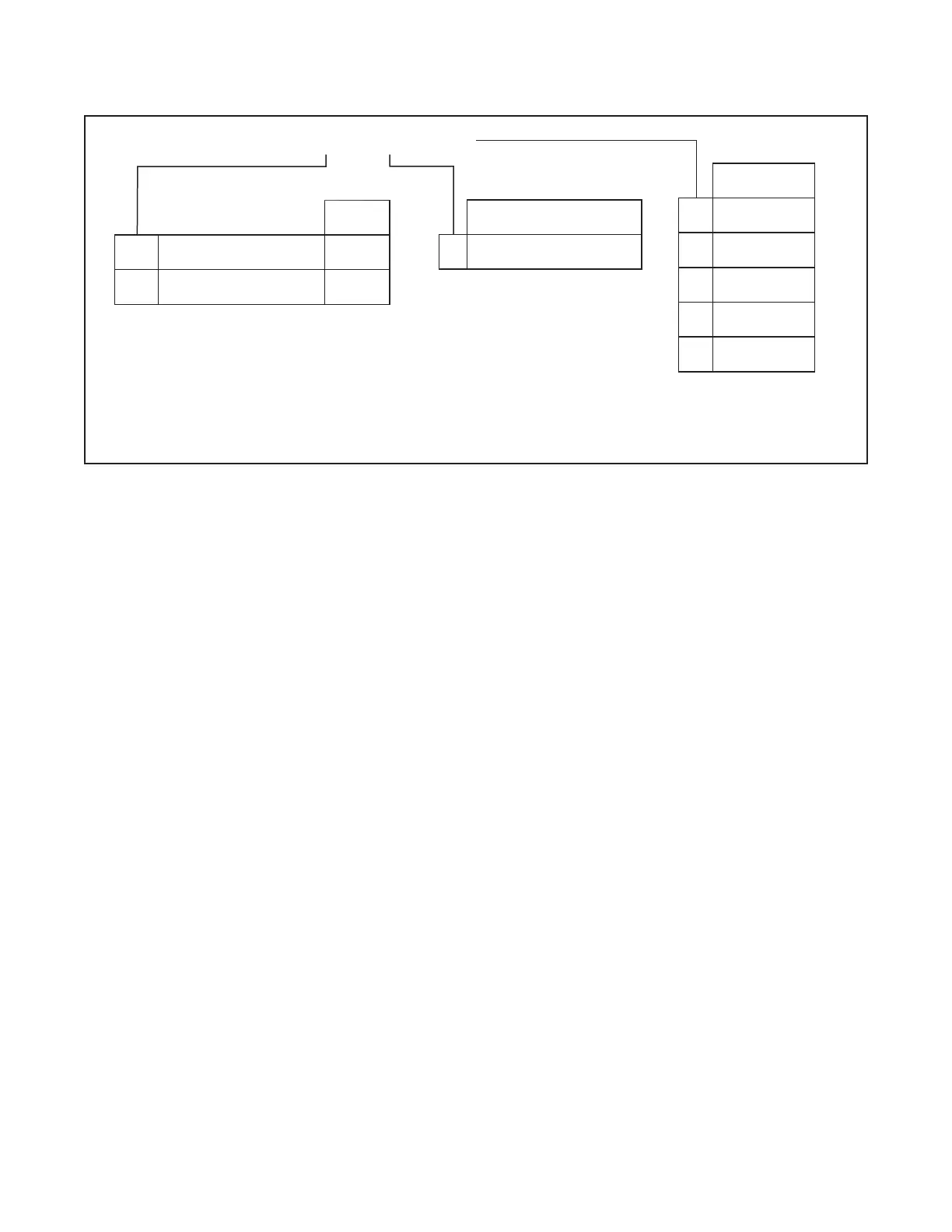

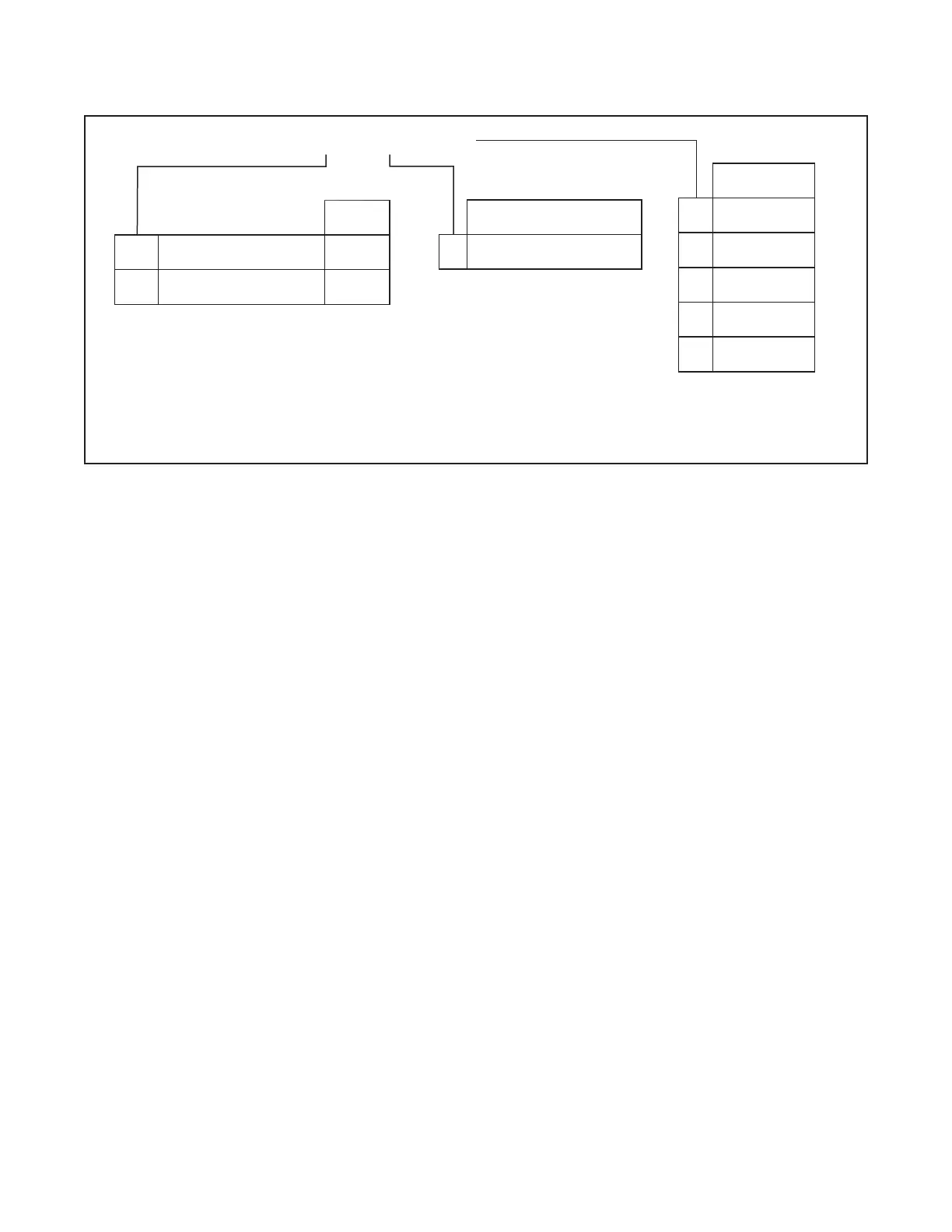

P/N 77 – XXX – X – XXX

SIN

370 5.6K UPRIGHT

2

(1/2˝ NPT)

1

TY313

371 5.6K PENDENT

3

(1/2˝ NPT)

1

TY323

TABLE B

SERIES TY-FRB UPRIGHT AND PENDENT SPRINKLERS

PART NUMBER SELECTION

SPRINKLER

FINISH

1 NATURAL BRASS

TEMPERATURE

RATING

135 135°F (57°C)

155 155°F (68°C)

175 175°F (79°C)

200 200°F (93°C)

286 286°F (141°C)

1. Use suffix “I” for ISO 7-1 connection, for example, 77-370-1-175-I

2. Upright G1/S1 Guard with Shield Assembly must be ordered

separately.

3. Model S2 Pendent Shield with O-Ring, and Optional Model G1 Guard

must be ordered separately.

Loading...

Loading...