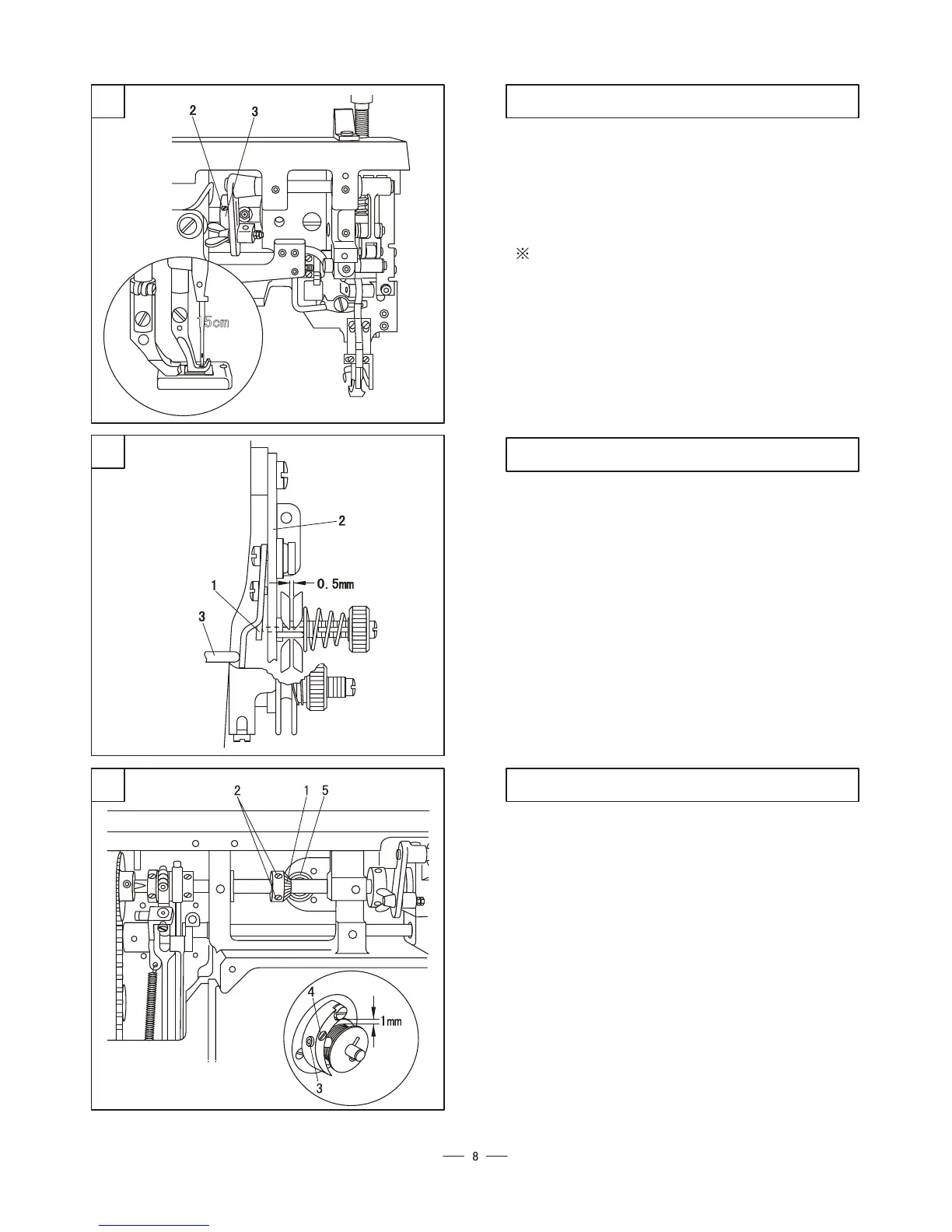

1717

1818

1919

1.Lower the presser foot on the needle plate;

2.Loosen the screw 2 until the feed eccentric wheel

can merely turn;

3.Adjust the feed eccentric wheel 3 as required;

4.Tighten the screw 2;

5.Test as required.

When the stitch length is at the max and the

presser foot touches the needle plate, the

walking foot and the needle should reach the

needle plate simultaneously.

18. Adjusting the upper feed(Fig.17)

When the presser foot is lifted up, there must be

a clearance of 0.5mm between the two tension

plates ( the minimum clearance is 0.5mm,

when sewing with thick thread, it should be

adjusted to 1mm,or more.

). Adjust the adjusting

plate as required.

When the presser foot is lifted up, there must be

a clearance of 0.5mm between the two tension

plates ( the minimum clearance is 0.5mm,

when sewing with thick thread, it should be

adjusted to 1mm,or more.

). Adjust the adjusting

plate as required.

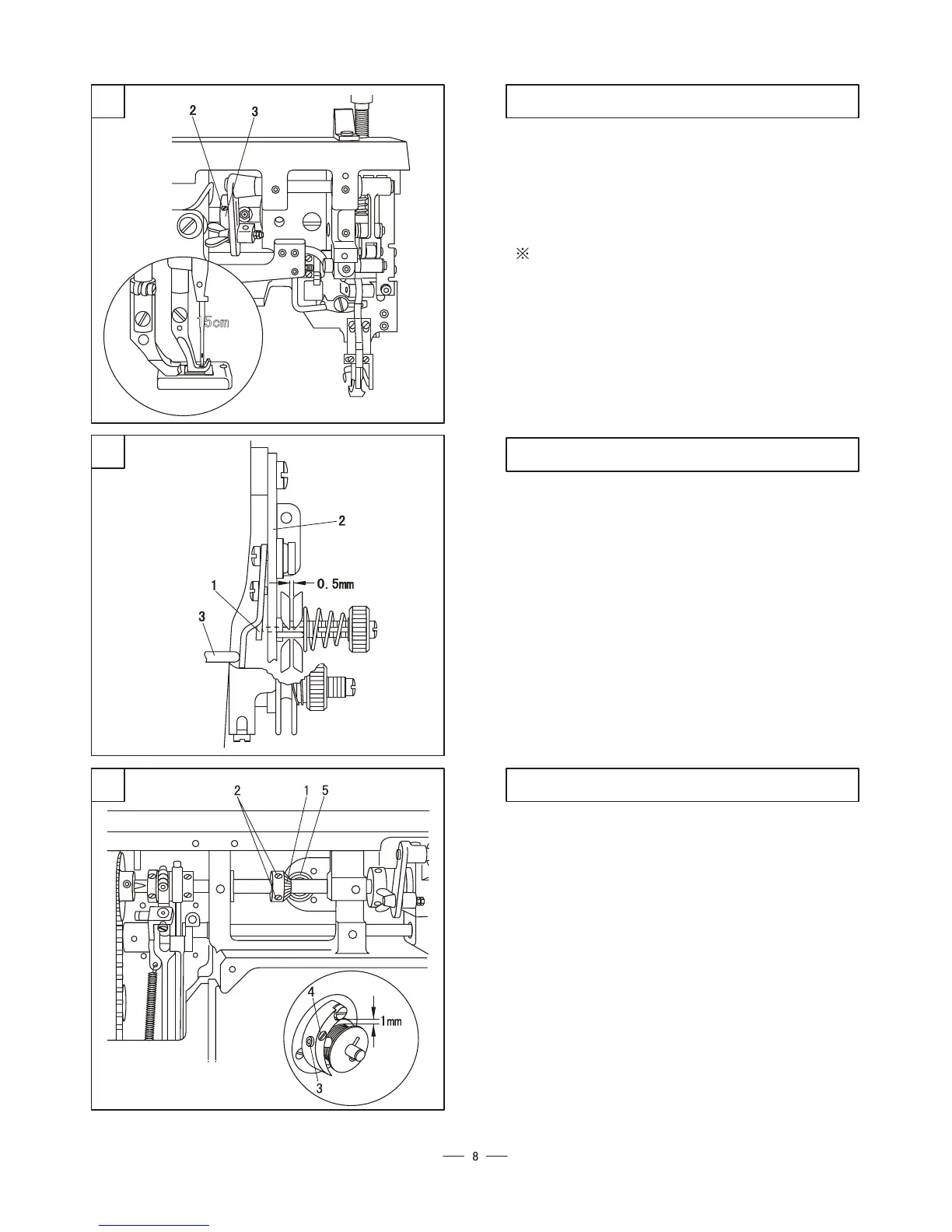

19. Needle thread tension releasing(Fig.18)19. Needle thread tension releasing(Fig.18)

1. When the winder switches on, its spindle must

engage reliable;when the winder switches off,

the friction wheel 5 and the driving wheel 1

should get apart;

2. When the thread is approx. 1mm from the edge

of the bobbin, the winder will switch off

automatically;

3. When operating, insert the bobbin to the winder,

thread the bobbin thread and switch the winder

on.Adjust the pin 3 and the screw 4 as required.

1. When the winder switches on, its spindle must

engage reliable;when the winder switches off,

the friction wheel 5 and the driving wheel 1

should get apart;

2. When the thread is approx. 1mm from the edge

of the bobbin, the winder will switch off

automatically;

3. When operating, insert the bobbin to the winder,

thread the bobbin thread and switch the winder

on.Adjust the pin 3 and the screw 4 as required.

20. Bobbin winder (Fig.19)20. Bobbin winder (Fig.19)

Loading...

Loading...