71

PLASTIC - ENGRAVERS

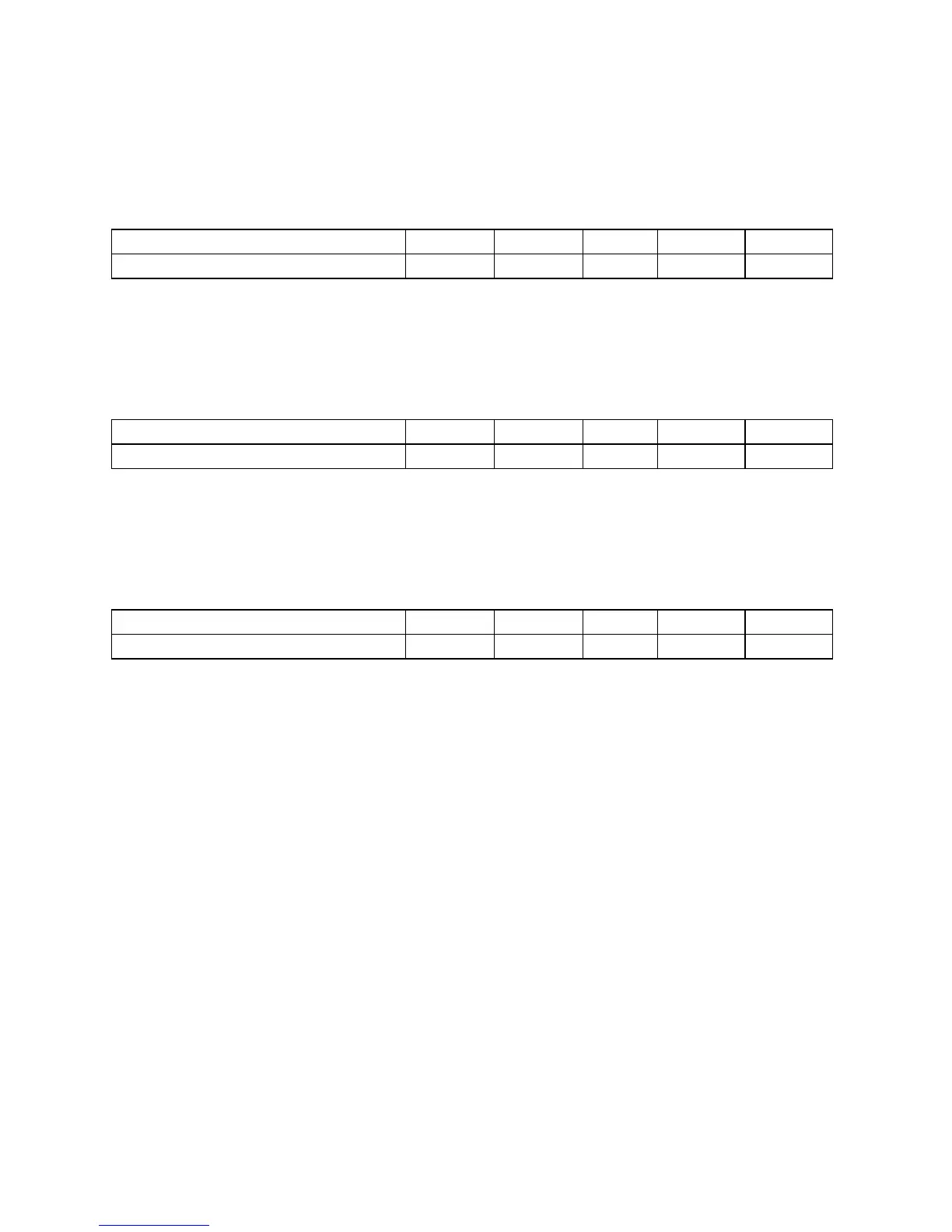

TYPE POWER SPEED PPI PASSES DEPTH

RASTER ENGRAVING 30 100 500 1 .003”

COMMENTS: Remove original masking and leave unmasked. Use enough power to remove the

surface material and expose the underlying substrate.

TYPE POWER SPEED PPI PASSES DEPTH

RASTER ENGRAVING (deep) 90 100 500 1 .015”

COMMENTS: On thicker plastics, remove the original masking and leave unmasked. Set the power

high enough to assure the full removal of the top surface and to remove some of the substrate material.

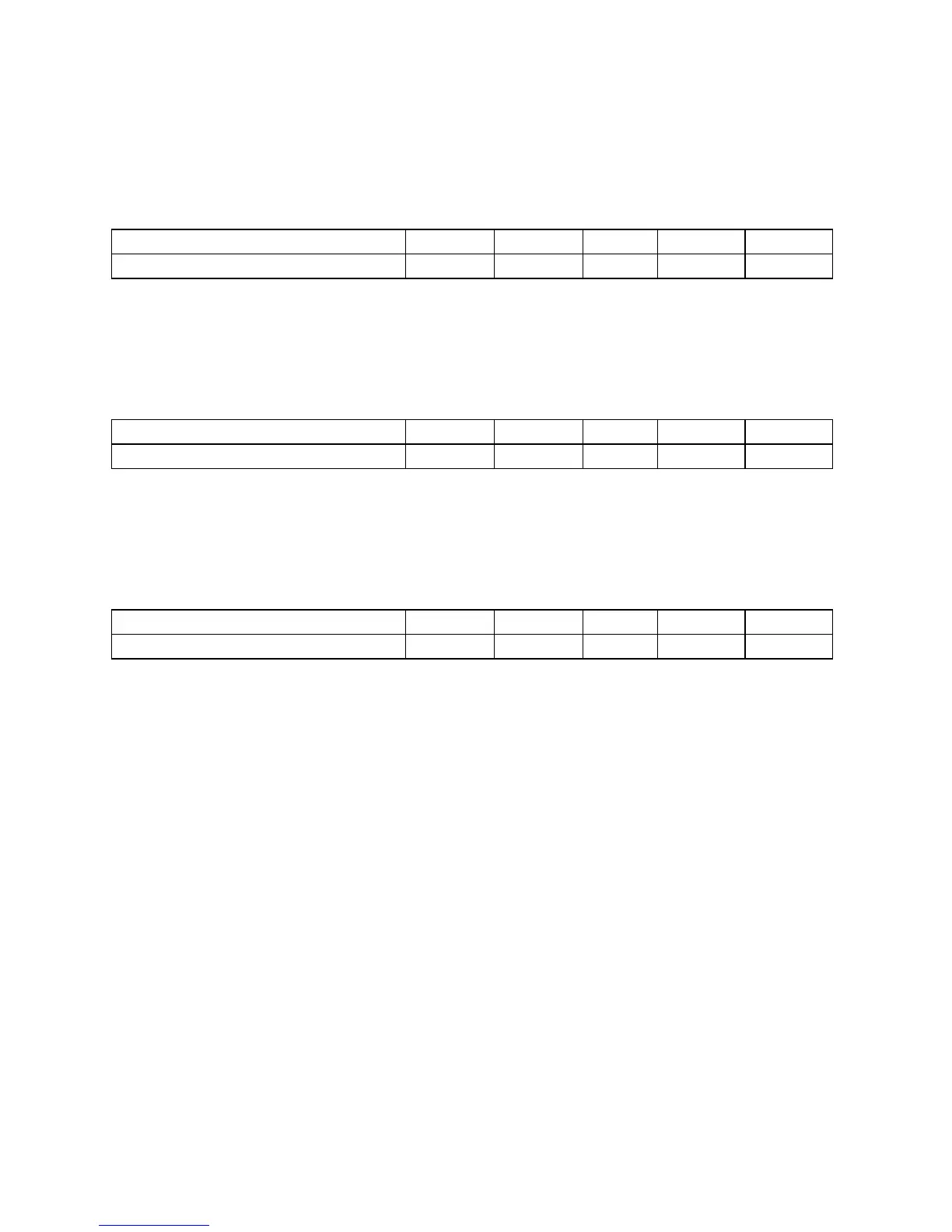

TYPE POWER SPEED PPI PASSES DEPTH

VECTOR CUTTING 60 1 150 1 .060”

COMMENTS: Remove original masking. Mask with transfer tape on both sides. Dampen both

sides with water and elevate off the engraving table. Remember to re-focus. Make 1 to 2 more passes

when cutting thicker plastics.

ADDITIONAL COMMENTS

Engravers plastic comes in many different colors, thicknesses, coatings, and surface textures. About

75 % of the available engravers plastic, including ADA signage materials, will engrave and cut well

with the laser system. Microsurfaced plastics seem to work the best because there is less surface

material to remove to uncover the substrate. Since most plastics have low melting points, a low PPI

setting is used when cutting to reduce the possibility of melting. Masking and dampening with water also

helps to reduce melting and keeps the plastic clear of smoke residue. Always remove the original clear

masking from the plastic because it does not react well with the laser. Since there are so many types of

engravers plastics, the only true way to find out if a particular brand and type will work well with the

laser is to experiment. Use these power settings as a guideline for experimentation and adjust as

Loading...

Loading...