73

RUBBER STAMPS

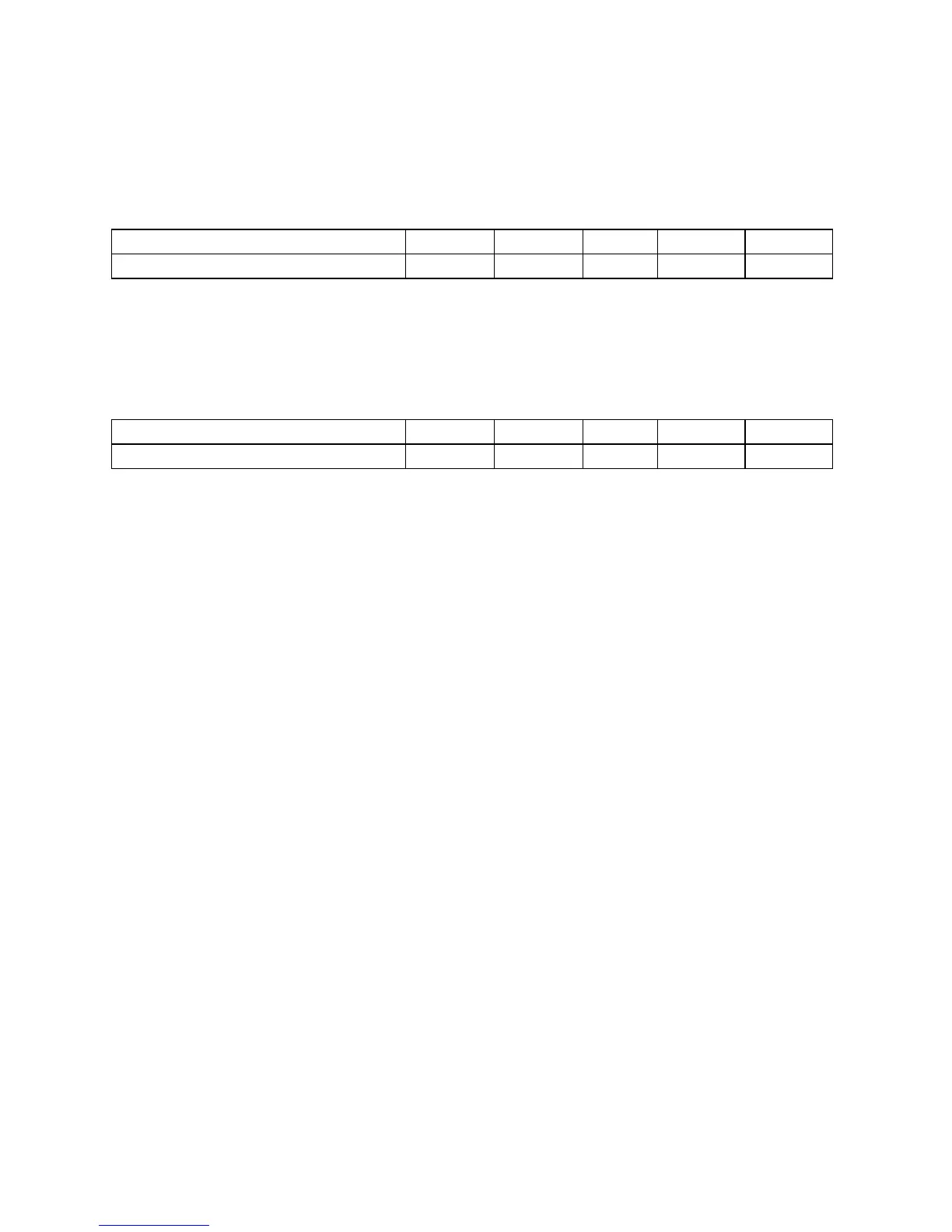

TYPE POWER SPEED PPI PASSES DEPTH

RASTER ENGRAVING 100 30 500 1 .040”

COMMENTS: Different blends and densities of rubber will engrave to different depths. Test the

rubber first to determine the correct power settings.

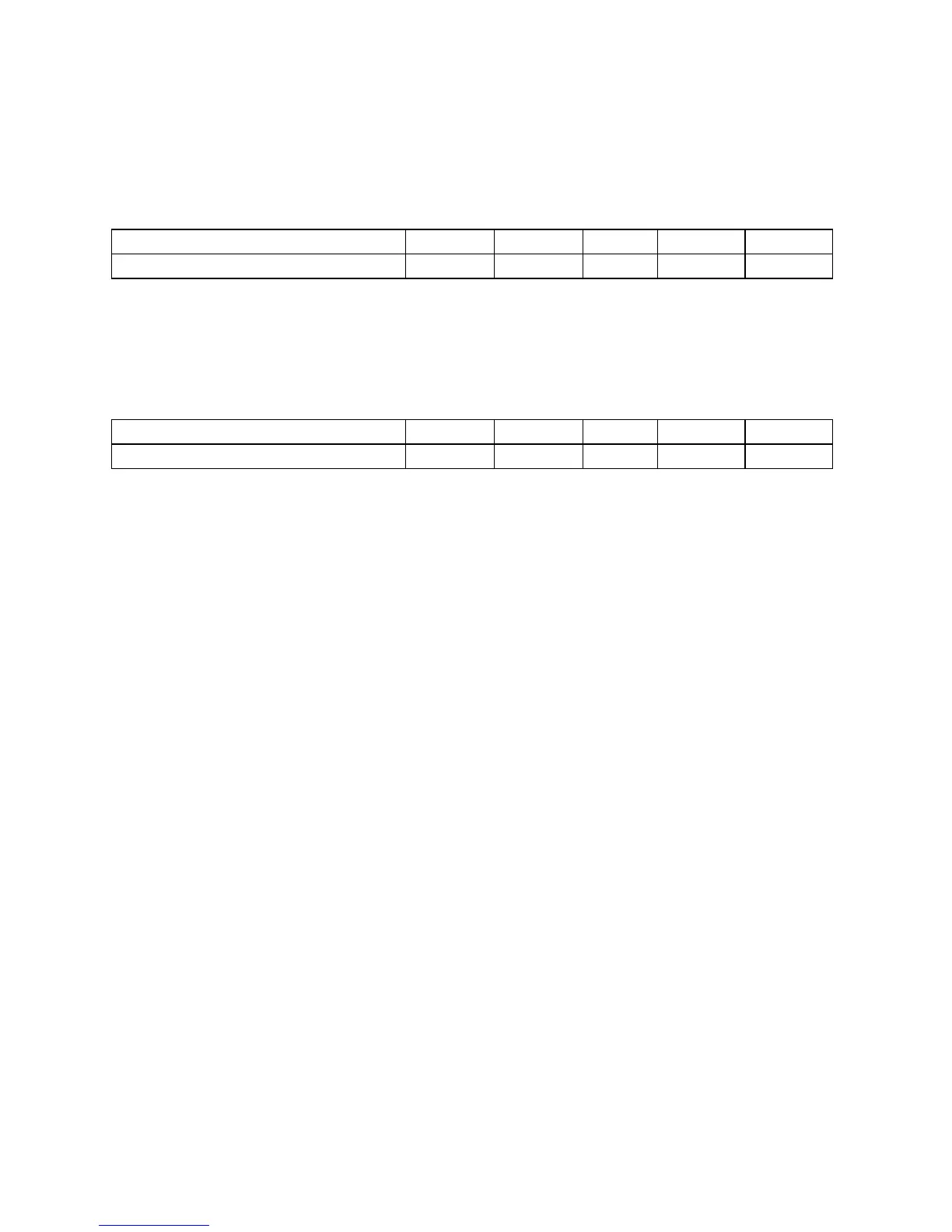

TYPE POWER SPEED PPI PASSES DEPTH

VECTOR CUTTING 40 1 150 1 .040”

COMMENTS: Keep the PPI low to prevent flaming while cutting.

ADDITIONAL COMMENTS

Our rubber stamp option is revolutionizing the rubber stamp industry. With special electronics and a

special system driver, it is possible to engrave rubber stamps with a profile and cut out the stamp in one

easy step. The machine produces a taper on each character so that the base of the character is wider

than the top printing surface giving greater stability when stamping. If trying to engrave stamps without

this option, the letters will not have a profile, be very thin and flimsy, and will collapse while stamping

them. If you do not have this option and would like to add it to your system, please contact one of our

engineers in the sales department for current pricing. All laser systems can be upgraded to have this

extraordinary feature.

In the above example, only one pass is necessary to achieve a deeply engraved rubber stamp. When

cutting out the rubber stamp, we recommend using a very low PPI setting. This setting spreads the

laser pulses far enough apart that they just touch at the edges. The result is a perforated cut that allows

the rubber stamp to remain attached to the entire sheet but easily removed by simply tearing it off. The

advantage to this is that the possibility of distortion or melting while cutting is virtually eliminated and the

entire sheet of rubber stamps can be removed from the machine at one time instead of having to pick

them up one by one. Some blends of rubber produce a powdery residue when engraved. Using

compressed air and blowing off the residue usually will clean the rubber effectively.

Loading...

Loading...