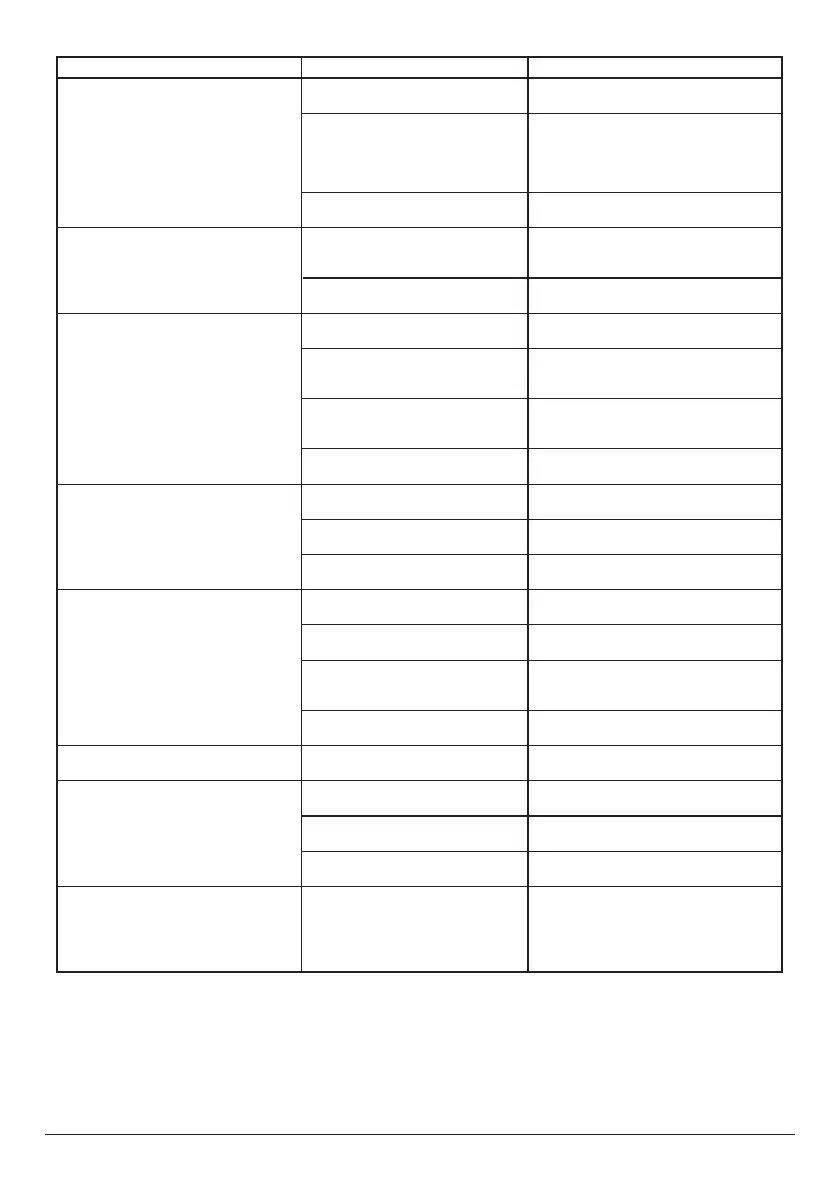

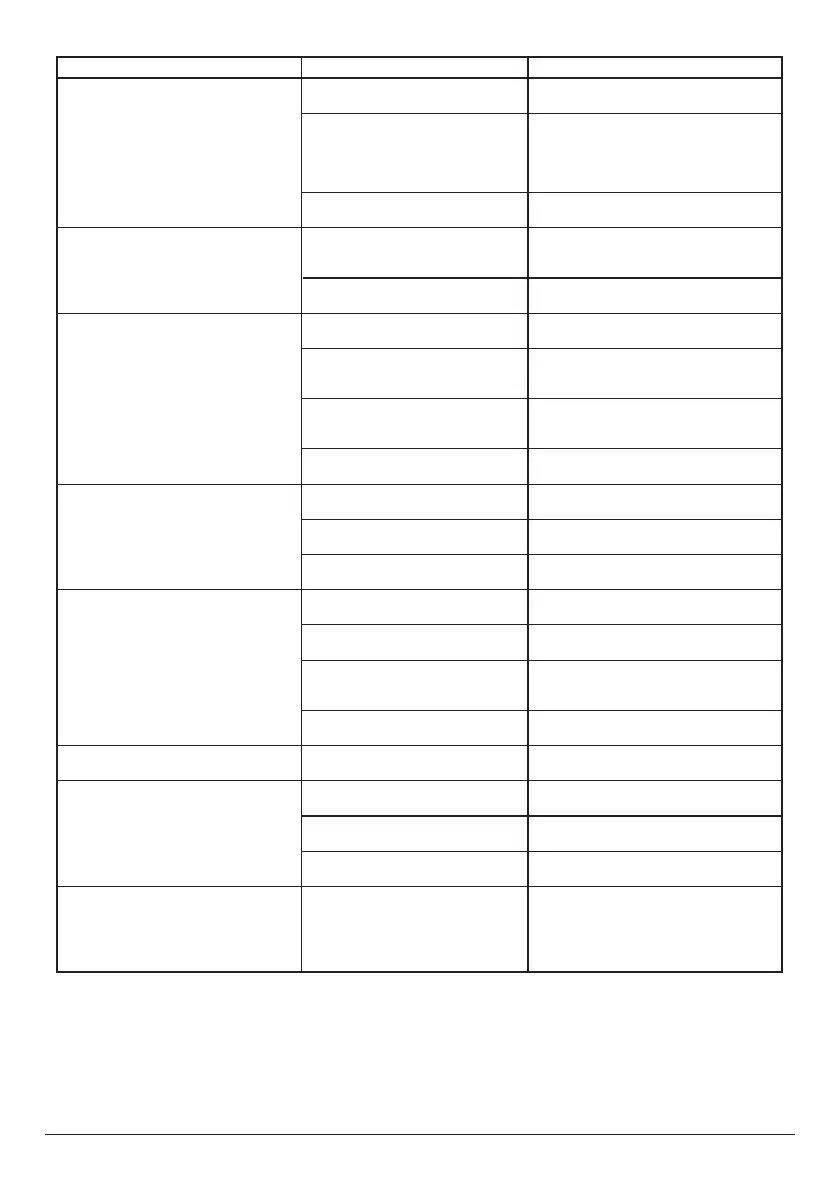

16

PROBLEM

CAUSE

SOLUTION

Low water pressure

Sediments in feeding line Clean the installation

Sediments in the softener

Clean control or conduct chemical

cleaning

Inlet of control plugged Wyjmij tłok i wyczyść głowicę

Resin flushed to drain

Air in water system

Assure the well system has proper

air eliminator control, check for dry

Inappropriate restrictor or DLFC Check restrictor

Resin in the installation

Cracked resin tank Seal or replace the tank

Broken tank elements

Replace broken pieces

Broken or incorrectly assembled

upper “basket”

Check basket assembly, contact

your local dealer

Contact your local dealer

Lack of upper basket

Excess water in brine

tank

Injector plugged Clean or replace injector

Clean flow control

Clean injector

Clean flow control

Clean the tank

Foreign material in brine tank

Plugged drain line flow

control (DLFC)

Softener fails to draw brine

Control cycles continuously

Plugged DLFC

Plugged injector

Low water pressure

Internal control leak

Increase water pressure to 3 bar

(recommended 4 bar)

Replace gaskets, spacers and/or piston

Replace gaskets, spacers and/or piston

Broken gear

Replace broken parts

Drain flows continuously

Inappropriate settings Check and correct the settings

Foreign material in control Clean control

Internal control leak

Soft water, but white

stains on the appliances

appear

Silica in water

Install sillica removal filter

Loading...

Loading...