- 20 -

3- Handling instructions

Leak test

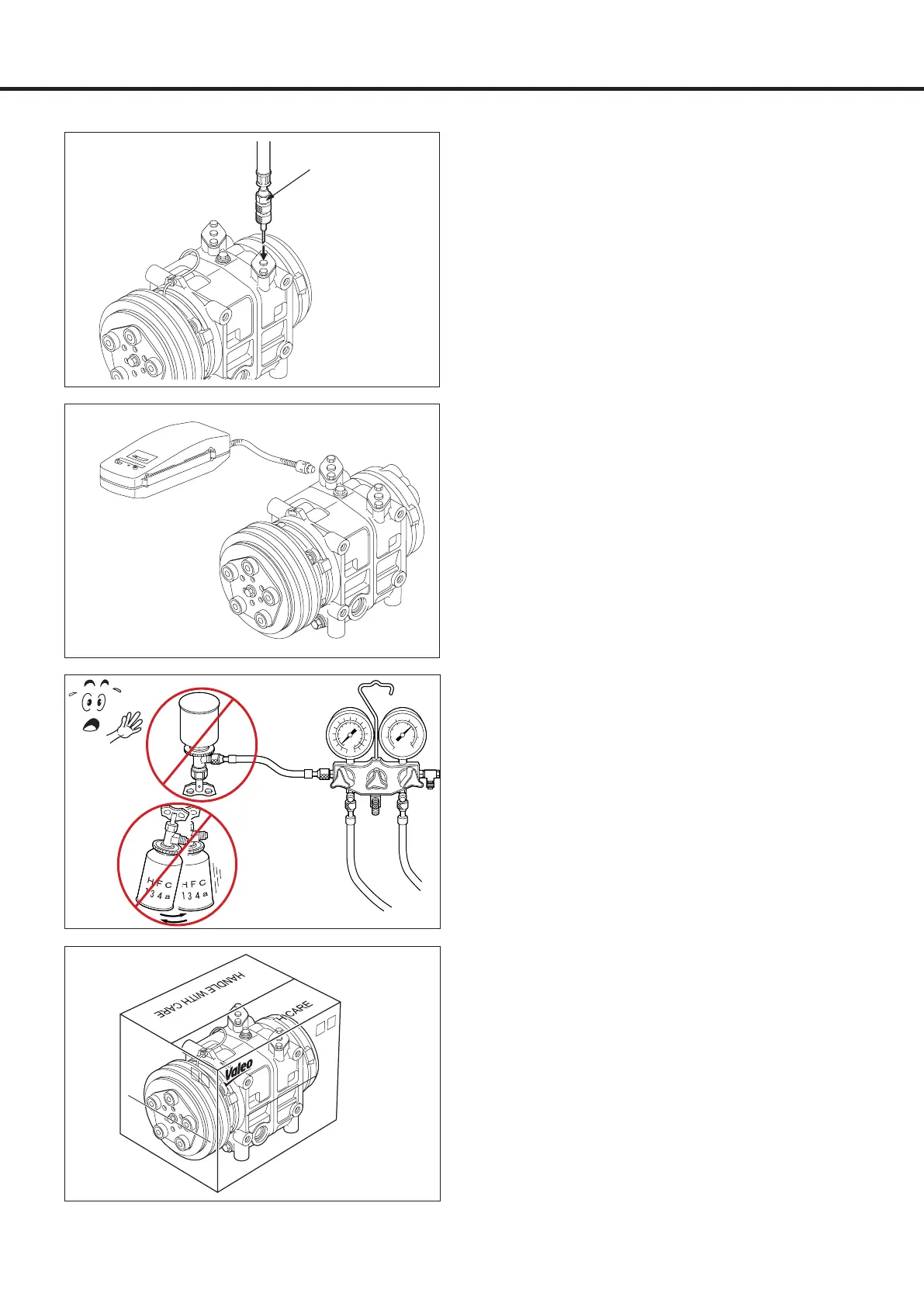

The compressor must be checked for refrigerant

leaks after it is repaired. The procedure is as

follows.

1. Fit plates to the suction and discharge

connections, and tighten it to the specified

torque.

Specified torque: 20 ~ 24 N·m

{2.0 ~ 2.4 kgf·m, 14 ~ 17 lbf·ft}

2. Using the valve assembly (597017-1120), fill

the compressor with refrigerant through the

suction side, raising the refrigerant pressure

to at least 0.49 MPaG {5 kgf/cm

2

, 71 psig}.

3. Check the compressor for leaks using a leak

detector.

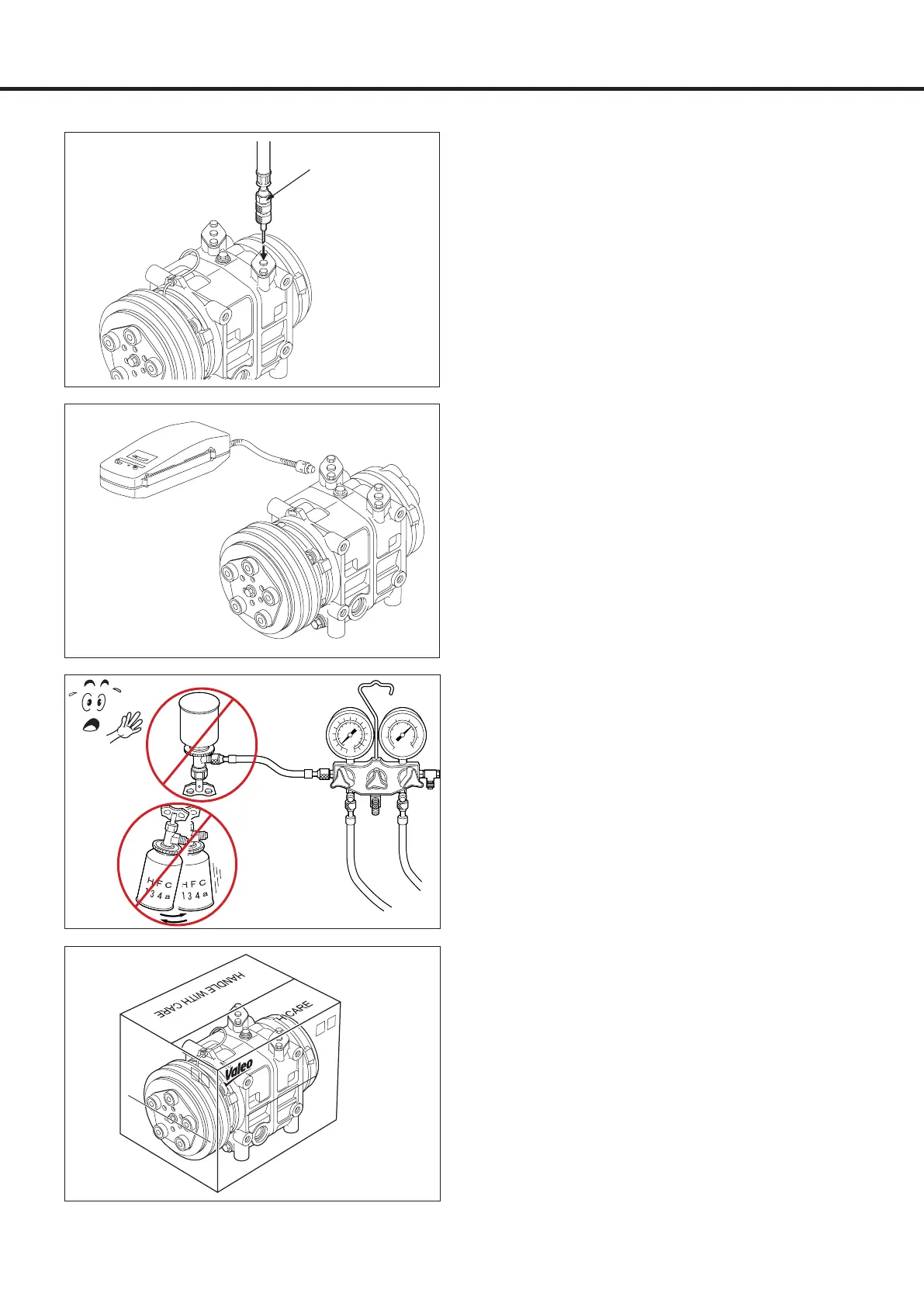

Refrigerant charging

In order to prevent a liquid charge and greatly

increase risks of compressor dammage, do not

shake or turn the refrigerant bottle upside-

down.

Storing a repaired compressor

If it is necessary to store a repaired compressor

for some time before installation, evacuate the

compressor and fill it with dry nitrogen gas

through the suction fitting to raise the pressure

to 49~150kPa {0.5~1.5kgf/cm

2

, 7.1~21psig}.

VALEO Japan Co Ltd,

MADE IN JAPAN

Air Conditioning

Compressor

FRAGILE

UP

FRAGILE

UP

Parts

No.

www.valeocompressors.com

Gas leak detector

597001-1020

Valve assembly

(597017-1120)

Loading...

Loading...