K6/K6N Vacuum Packaging Machine

Maintenance

2002-04-25 Art. no. 519.340 Page 45/56

Replacing welding wire and cutting wire

§ Removing the Teflon strip as described above.

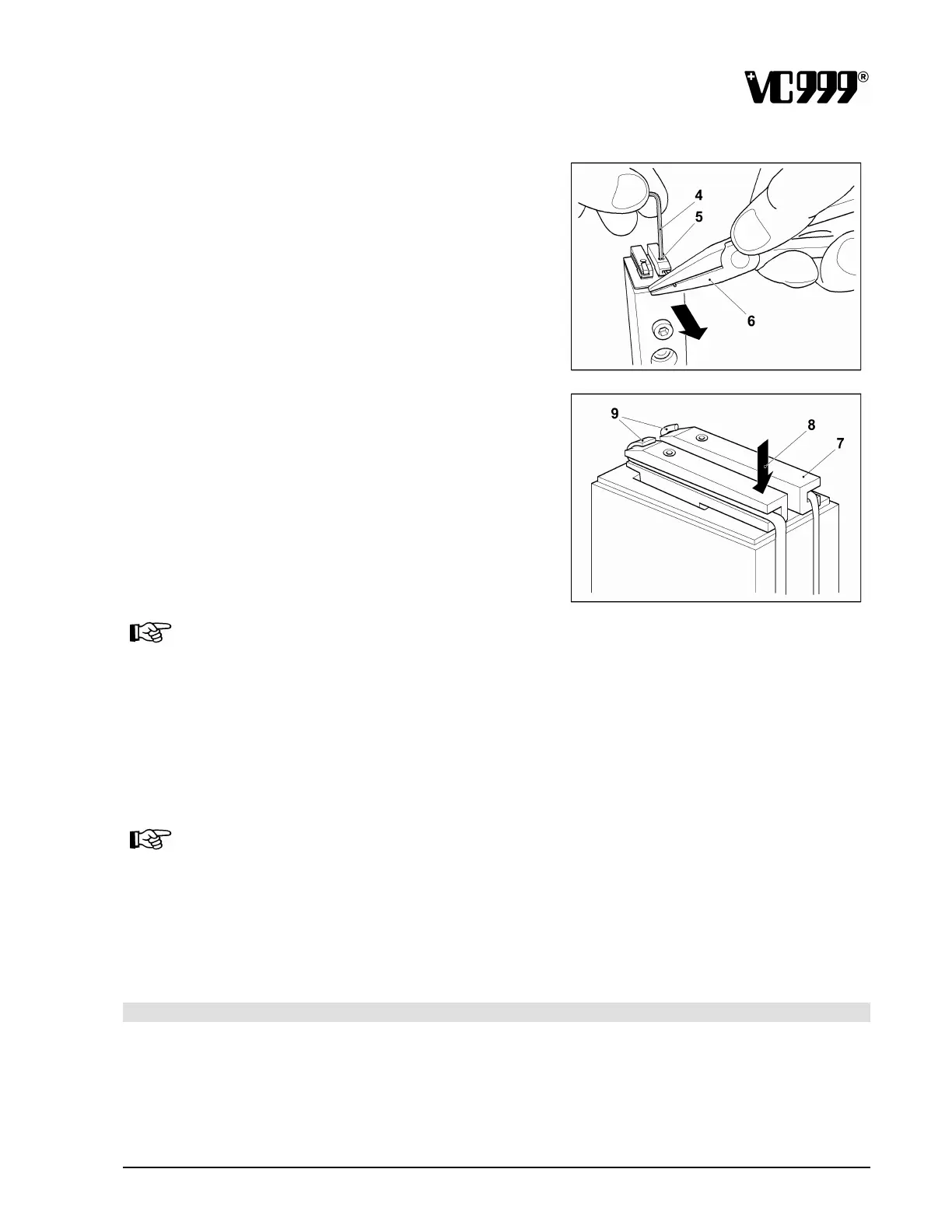

§ Use a hexagon socket head wrench (4) to remove

the threaded pin (5).

§ Also loosen the threaded pin on the other side

and insert a new wire. Secure it to the other side

using the threaded pin.

Fig. 13/3

§ Tighten it by pulling it through the clamping jaws

(7) using pliers (6).

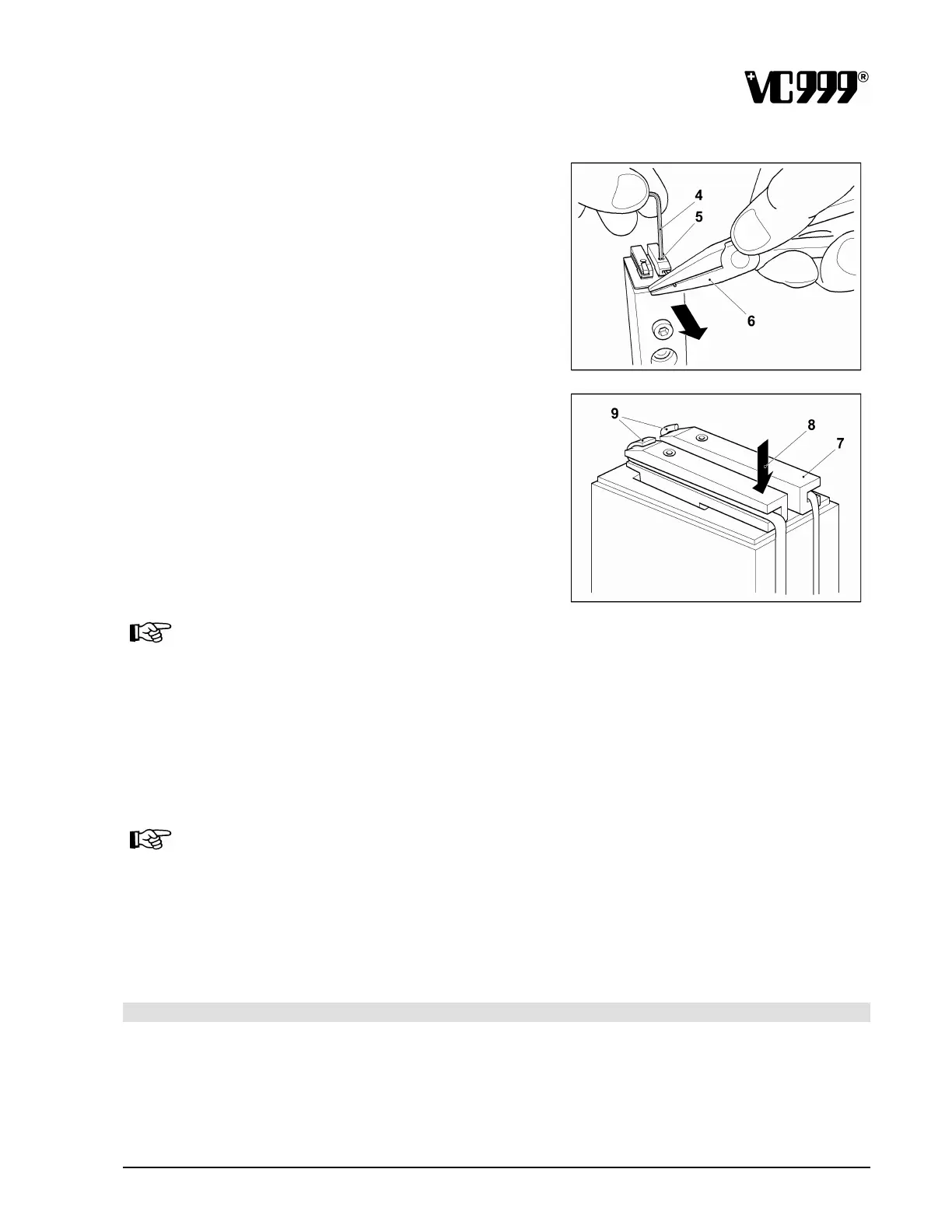

§ Before you tighten the wire with the threaded pin,

press the clamping jaws as far as possible against

the welding bar (8).

§ Tighten the threaded pin and bend the protruding

end of the wire (9) over the clamping jaws.

Fig. 13/4

IMPORTANT

The clamping jaws (7) are pretightened with compression springs. You can tell that the wires

are correctly tightened if all 4 clamping jaws are pressed in as far as they will go (8)!

§ Attach the Teflon strip to the welding bar, as described above.

Installing the welding bar

§ Locate the welding bar onto the two guide pegs and push it upwards as far as it will go.

IMPORTANT

Ensure that it is installed in the correct position: with the flat welding wire against the inside of

the vacuum chamber and with the locking levers pointing outwards!

§ Secure the welding bar in place by turning the two locking levers through 90° into a horizontal

position. Try to move it in the opposite direct to ensure that it is properly fixed in place.

13.3.3 Maintenance of the welding cap pass

§ Replace the silicone strip if it is damaged. It is pressed lightly into the channel on the welding cap

pass and is easy to remove.

§ If this happens, also clean the welding bars, following the instructions in the section above.

Loading...

Loading...