46

PHTM II

Installation, Operating & Service Instructions

110331-01 - 5/20

WARNING

Burn Hazard.

Never exceed maximum allowable working

pressure on heat exchanger ASME plate. (50

psig (210 kPa) A 30 psig safety relief valve is

included with this boiler.

15 Start-Up and Checkout

Heating System Cleaning and Treatment

1. Prior to fill, flush entire heating system to remove

sediment, flux, and traces of boiler additives.

2. Clean with approved cleaners such as the

following or its equivalent:

• Fernox Cleaner F3 (for new heating systems)

• Sentinel x300 System cleaner (for new heating

systems)

• Sentinel X400 System Restorer (for old closed

loop hydronic systems)

Refer to instructions supplied with cleaner for

proper dosage and use.

CAUTION

Component Damage.

Avoid use of petroleum based boiler additives

and ester-based oils/lubricants. These could

attack seals in both boiler and system which

could result in property damage.

Fill Water Quality

NOTICE: Make sure system is filled with water

meeting the following criteria:

• Hardness less than 7 grains/gallon.

• pH between 6.5 and 9.5 (for systems containing

aluminum components, between 6.5 and 8.5)

• Chlorides less than 200 PPM. If fill water is

drawn from a system containing a water softener,

test a sample of the water to confirm that this

criteria is met.

Following appropriate water chemistry guidelines will

help extend the life of appliance by reducing effects

of lime scale buildup and corrosion. which could void

warranty.

NOTICE: Minimize introduction of make-up water,

dissolved oxygen, and contaminants into boiler by

following installation guidelines outlined in Appendix

B: Water Quality and Boiler Additives.

Freeze Protection

If freeze protection is required see Appendix B for

additional information.

Fill Water System

1. Fill system ensuring water quality meets

requirements of this manual.

2. Fill to correct system pressure. Pressure will vary

with each application.

3. Pressurize system to at least 12 psi at boiler.

!

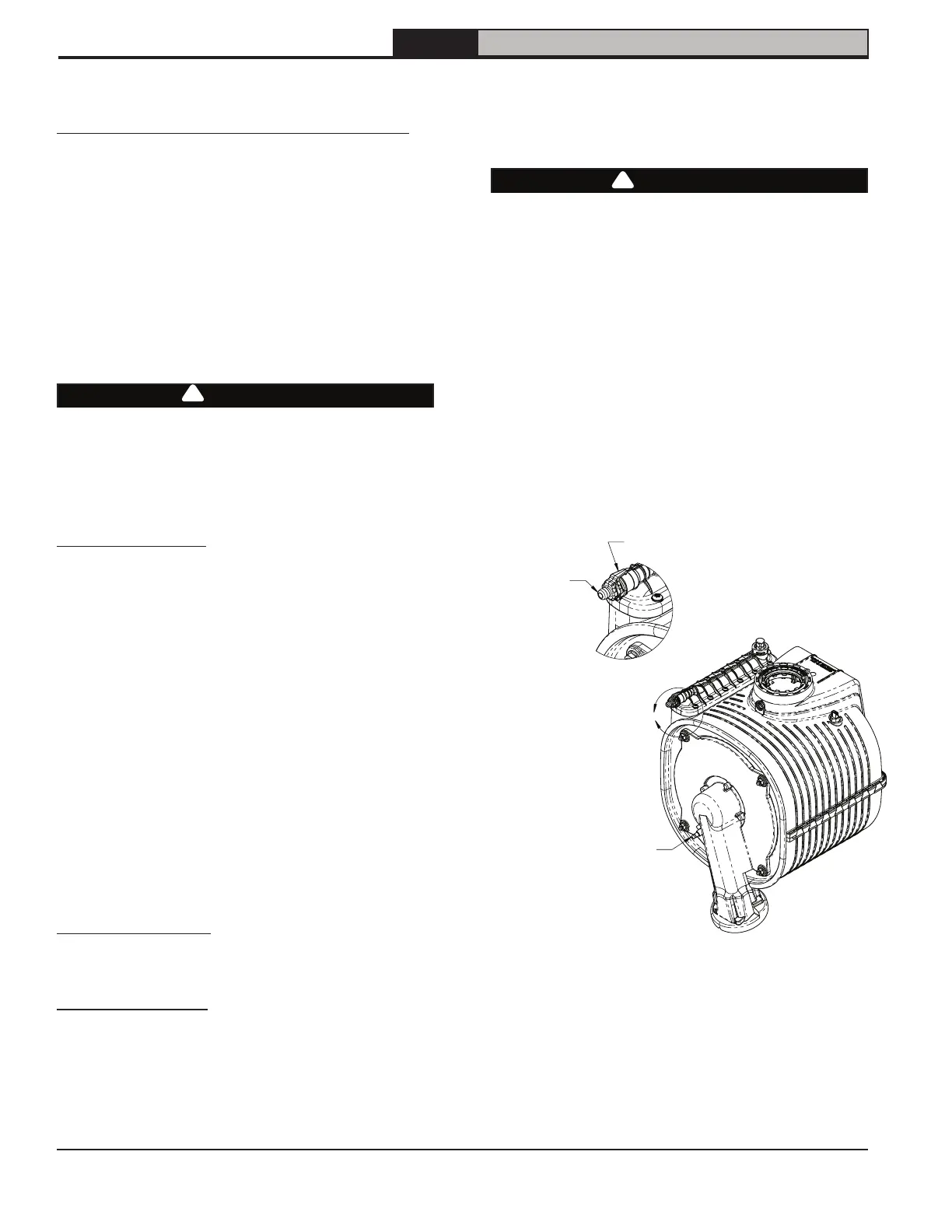

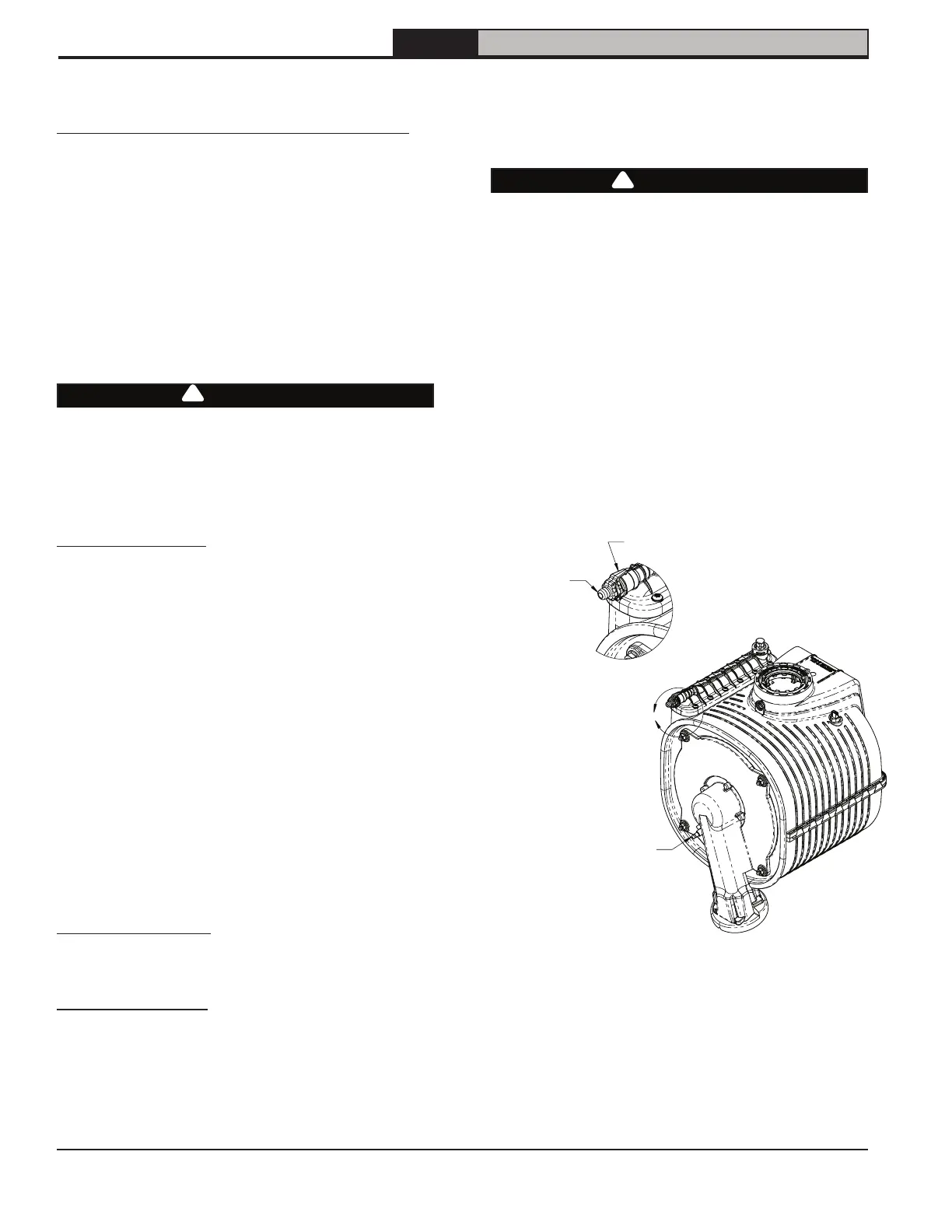

5. Eliminate air in boiler by bleeding from heat

exchanger manual air vent on top left side of heat

exchanger (Figure 15-1).

A. Use 1/4 in. (6 mm) ID tubing connected to

hose barb and route tubing to a safe draining

location.

B. Turn vent counter clockwise and allow heat

exchanger to vent until a steady stream of

water is observed.

C. Close vent and remove hose.

Figure 15-1: Manual Air Vent Location

6. Isolate each zone to purge air confirming that

heating system and boiler are completely filled.

7. Verify automatic air vent located on internal piping

is open and remains open to atmosphere. See

Figure 4-1 for location.

!

A

Flame Rod

Detail A

(Scale 2:1)

Manual Air Vent

Confirm 1/4" ID

tubing is connected

to hose barb. Route

tubing to a safe place

away from controls

before opening vent.

4. Verify air pressure in expansion tank is equal to

system pressure.

Loading...

Loading...