73110331-01 - 5/20

PHTM II

Installation, Operating & Service Instructions

19 Troubleshooting (continued)

D. Troubleshooting with Active Fault Code.

Control uses following codes to describe abnormal operation:

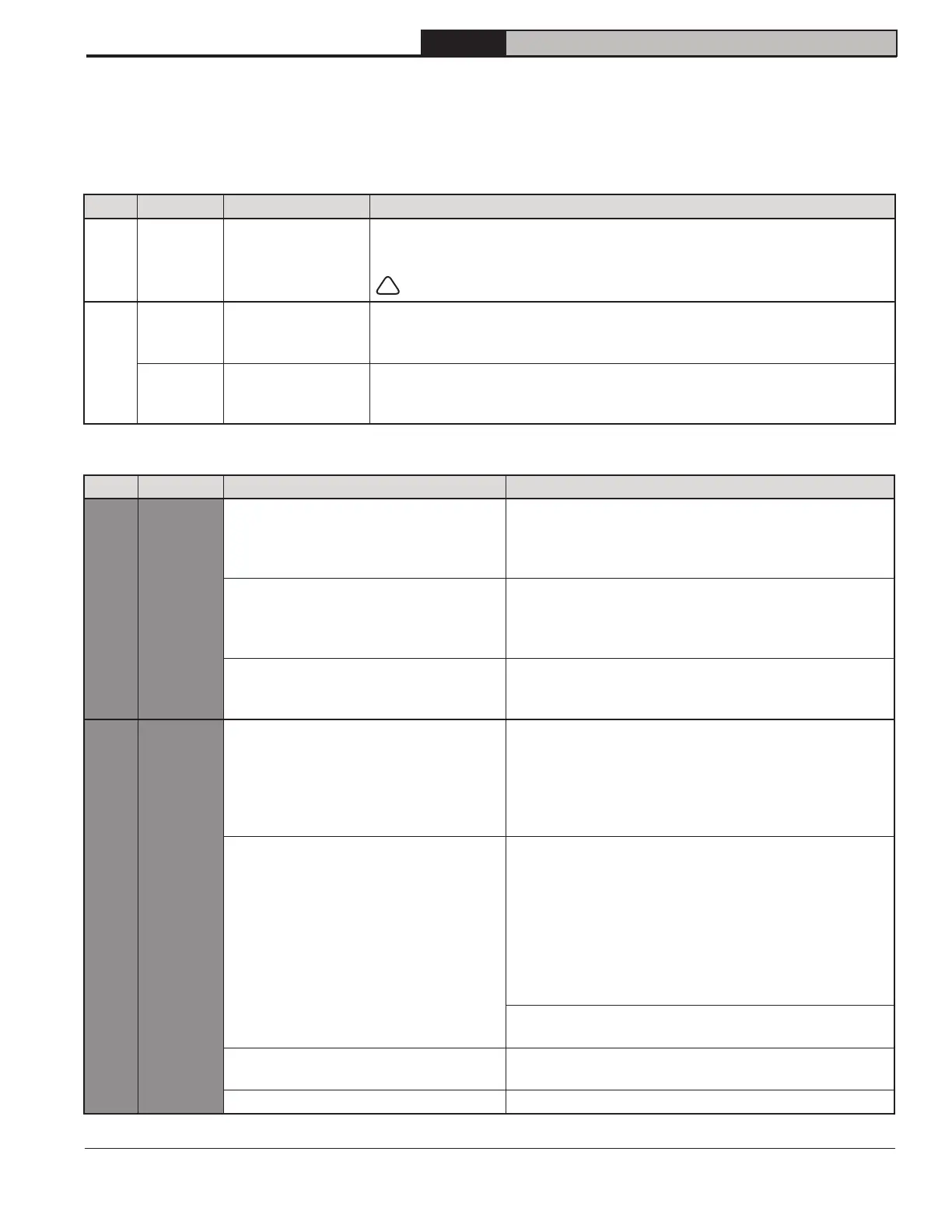

Table 19-4: Lockout/Hold/Warning Symbol Description

Code Type Boiler Status Description

E Lockout Shutdown

When a lockout occurs, boiler will shut down and event is stored in

history, b, menu. Once condition that caused lockout is corrected,

boiler remains shut down until a reset has been performed by pressing

!

reset button.

H

Hold Shutdown

When a Hold occurs, boiler will shut down. Event is stored in history, b,

menu. Boiler will automatically restart once condition that caused hold is

corrected.

Warning Free to operate

When a Warning occurs, an abnormal condition has affected boiler

operation and event is stored in history, b, menu. Boiler continues to

operate.

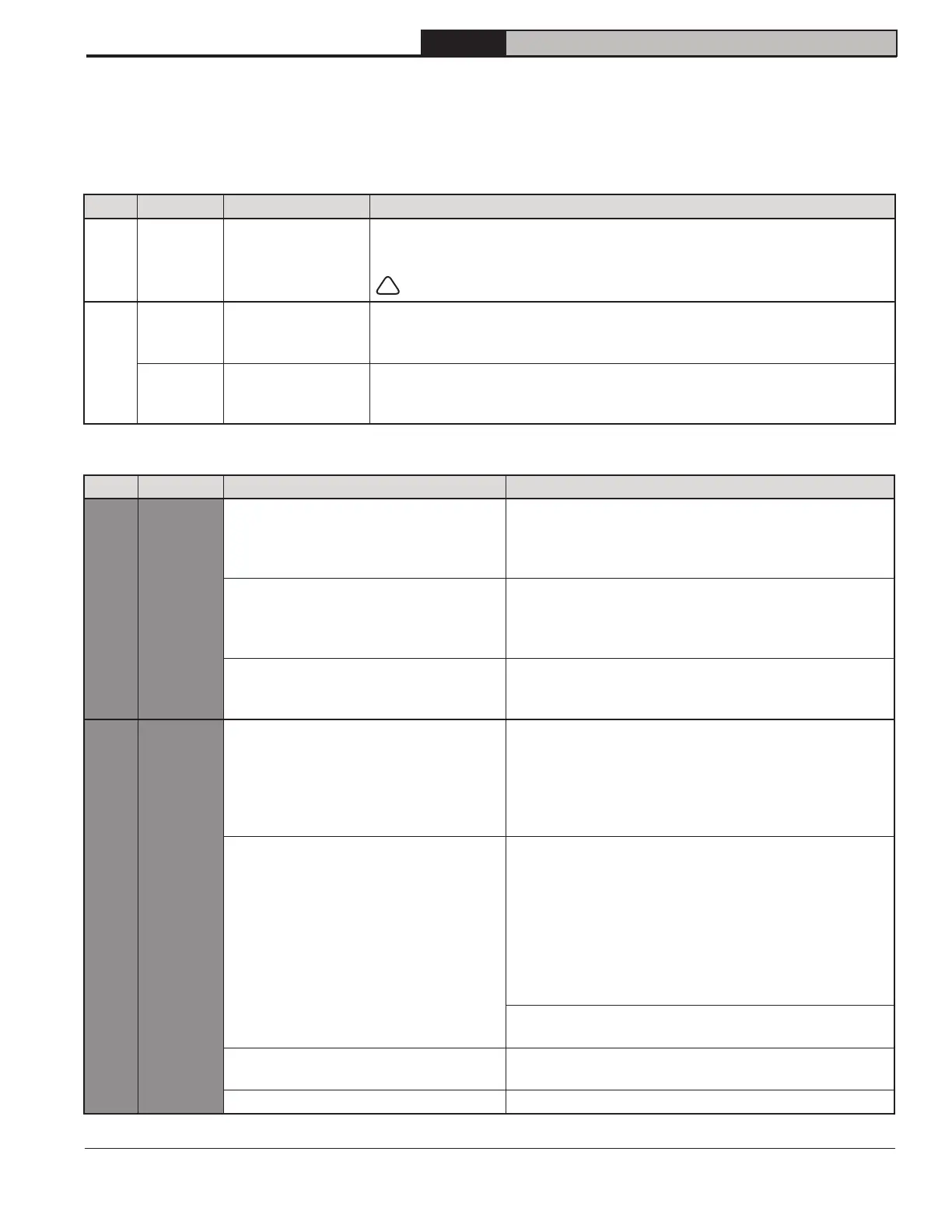

Table 19-5: Active Fault Code and Corrective Actions

Code Name Possible Causes Corrective Action

H01

Anti-

Short

Cycle

[1.0] Anti-short cycle boiler start delay,

while thermostat demand present,

boiler has cycled off and restart is

delayed.

Boiler will restart after minimum off time of 1 minute.

[1.1] Urgent calibration cooling delay

boiler start delay, urgent calibration

is present, waiting for supply

temperature to decrease.

Boiler will start after supply temperature drops below

95°F (35°C). Low supply temperature helps to ensure

a successful calibration.

[1.2] Flow switch closed delay boiler

start delay, flow switch is closed,

waiting for flow switch to open.

Boiler pump will start after flow switch open state is

proven. Maximum waiting time is 30s, otherwise E5.4

is set.

H02

Safety

Limit

Open

External limit.

If water temperature too high see H04/E04 for

corrective action.

• Check external limit setting, verify limit setting.

• Check external limit wiring.

• If external limit is not used, check jumper is installed

according to wiring diagram.

Optional (LWCO)

Check LWCO indications, if yellow light "On":

- Verify that system is full of water and all air has

been properly purged from system.

- Check automatic air vent is unobstructed and

properly functioning, a blocked air vent can result

in low water condition.

If yellow and green light "Off", check LWCO wiring

harness.

If LWCO is not used, check jumper is installed

according to wiring diagram.

Thermal Fuse.

Check thermal fuse for continuity. If "open" consult

manufacturer.

Loose wire. Check limit string wiring.

Loading...

Loading...