75110331-01 - 5/20

PHTM II

Installation, Operating & Service Instructions

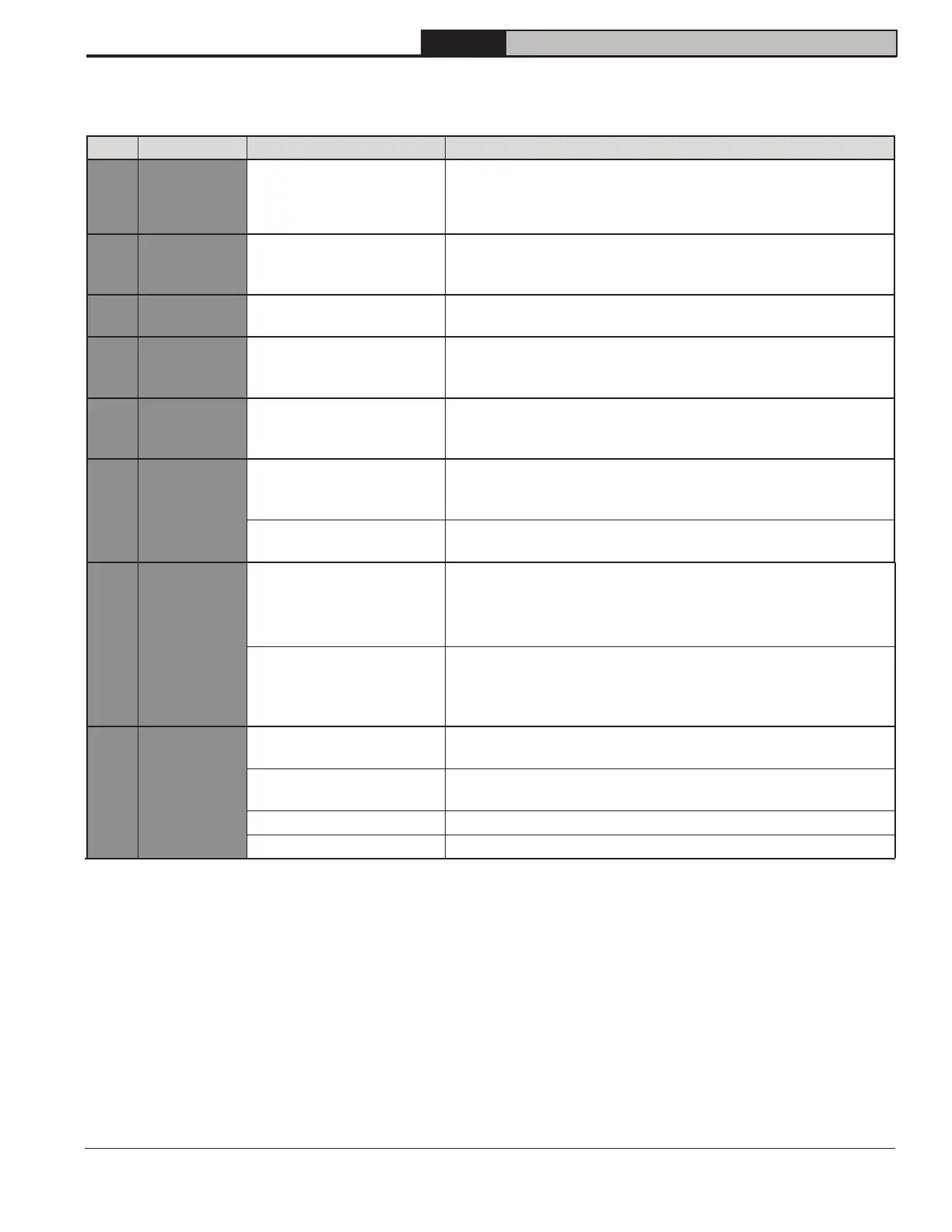

H06

E06

Flue

High

Limit

Heat exchanger dirty.

• Inspect heat exchanger. Refer to Section 18 Service

and Maintenance for guidance to clean flue side of heat

exchanger.

• Verify vent/air intake pipes are properly installed and

unobstructed.

Boiler over-fired Consult manufacturer.

H07

Return

Temp

Higher

Supply

Flow through boiler reversed.

Verify correct piping and pump orientation. Refer to Figure

10-2 in this manual.

Supply or return sensor defective

or not installed properly.

Check supply and return sensors, correct installation or

replace if required.

No boiler water flow.

Verify system is purged of air and that appropriate valves

are open. Also verify pump is running and set to speed 3

(Figure 15-2).

H08

Return

Sensor

Fault

Shorted or miswired return

temperature sensor.

• Check return sensor wiring, correct wiring if necessary.

• Check return sensor. Refer to Table 19-7. Replace if

necessary.

19 Troubleshooting (continued)

Table 19-5: Active Fault Code and Corrective Actions (continued)

Code Name Possible Causes Corrective Action

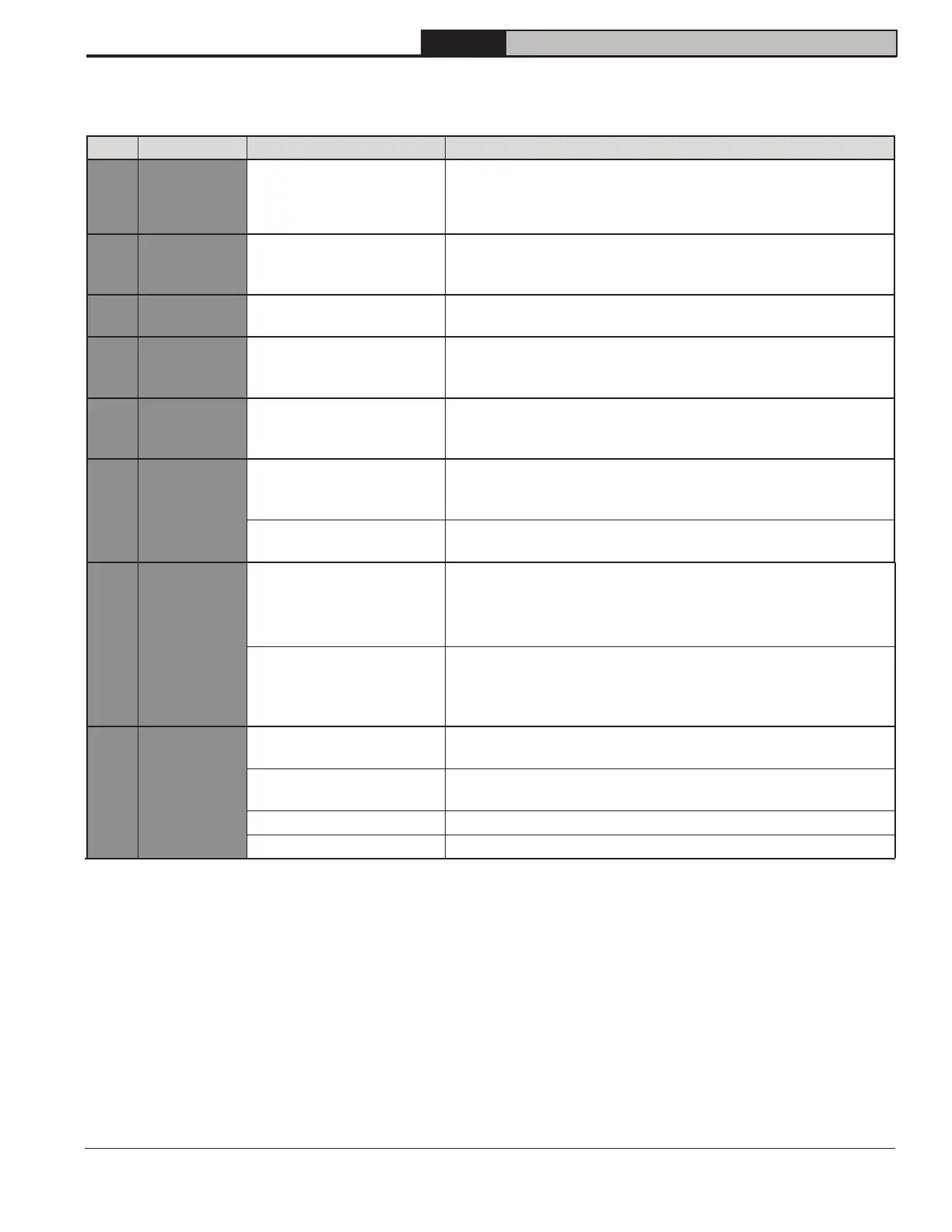

H09

E09

Supply

Sensor Fault

Shorted or miswired

supply temperature

sensor.

Check supply sensor wiring, correct wiring if necessary.

Measure resistance of each thermistor and compare. Refer to

Table 19-7. Replace sensor if necessary.

H10

DHW Sensor

Fault

Shorted or miswired DHW

temperature sensor.

• Check DHW sensor wiring, correct wiring if necessary.

• Check DHW sensor. Refer to Table 19-7. Replace if

necessary.

H11

E11

Flue Sensor

Fault

Shorted or miswired flue

temperature sensor.

• Check flue sensor wiring, correct wiring if necessary.

• Refer to Table 19-7 Replace sensor if necessary.

H12

Outdoor Air

Sensor Fault

Shortened or miswired

outdoor air temperature

sensor.

Check outdoor air sensor wiring, correct wiring if necessary.

Check outdoor sensor, Refer to Table 19-8.

H13

Header Or

Recirculation

Sensor Fault

Shorted or miswired

header or recirculation

temperature sensor.

Check header or recirculation sensor wiring, correct wiring if

necessary. Check Header sensor, Refer to Table 19-7.

H14

0-10V/4-

20mA Input

Fault

Shorted or miswired

0-10Vdc / 4-20mAdc

input.

Check 0-10/4-20 input wiring, correct if necessary.

Analog input parameter

setup incorrect.

Check and correct parameter settings (feature not available

with local user display).

E15

APS

Defective

The air pressure switch is

defective, failed to open.

• Remove jumper from air proving switch.

• Check switch, combine with below connection and wiring.

Check switch air tube is connected and unobstructed.

Replace if necessary.

The blower is running

when it should not.

Blower is running before start sequence. This can be caused

by a loss of communication between blower and control

resulting in blower going to max speed. Possible cause is a

defective wiring harness, blower or control.

H16

E16

Low

Combustion

Air Flow

Defective air proving

switch.

Check switch, connection and wiring. Check tube is

connected and unobstructed. Replace if necessary.

Air flow is blocked.

Check vent, air inlet, heat exchanger and burner. Remove

obstruction.

Blower wiring fault. Check power and speed control wiring to blower.

Blower Damaged. Check blower and replace if necessary.

Loading...

Loading...