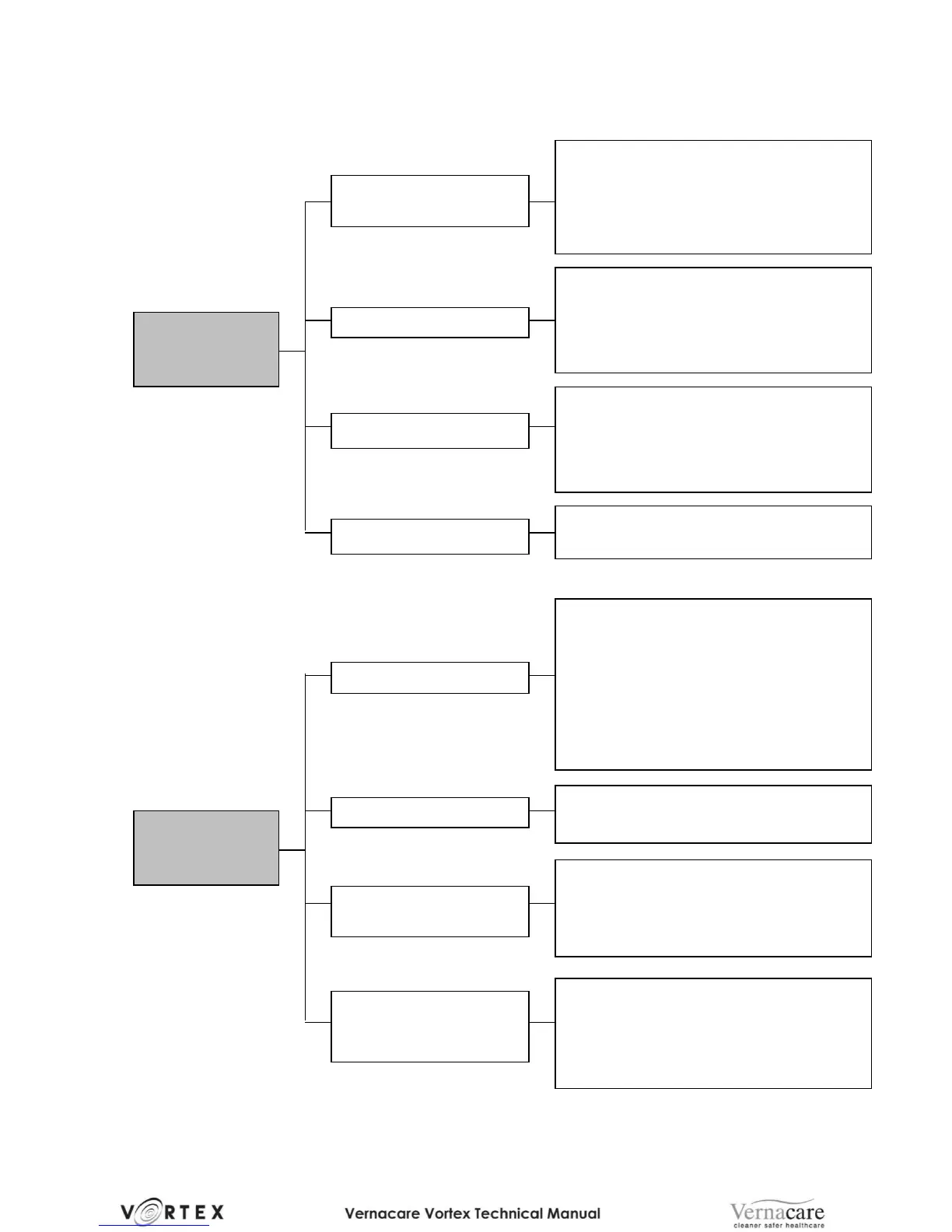

Check if water is leaking from the motor

drain hole - Replace damaged seal.

Check the water feed pipe connection

to the seal – Repair.

Check diaphragm sealing joint –

Replace.

Check pipe clips – Tighten.

Check condition of pipes – Replace.

Check joint lid arm inlet pipe – Replace

pipe if cracked / tighten clip.

Check lid arm sealing inlet block seal to

arm moulding – Re seal joint.

Check gasket on motor flange –

Replace.

Lid seal

leaking.

Bubbling

Debris on the seal face – Clean.

Check lid arm alignment – see fault 4.

Hinge bushes worn – Replace.

Check condition of lid seal – Replace.

Check operation of lid handle insert –

Repair.

Check seal is seated correctly - Replace

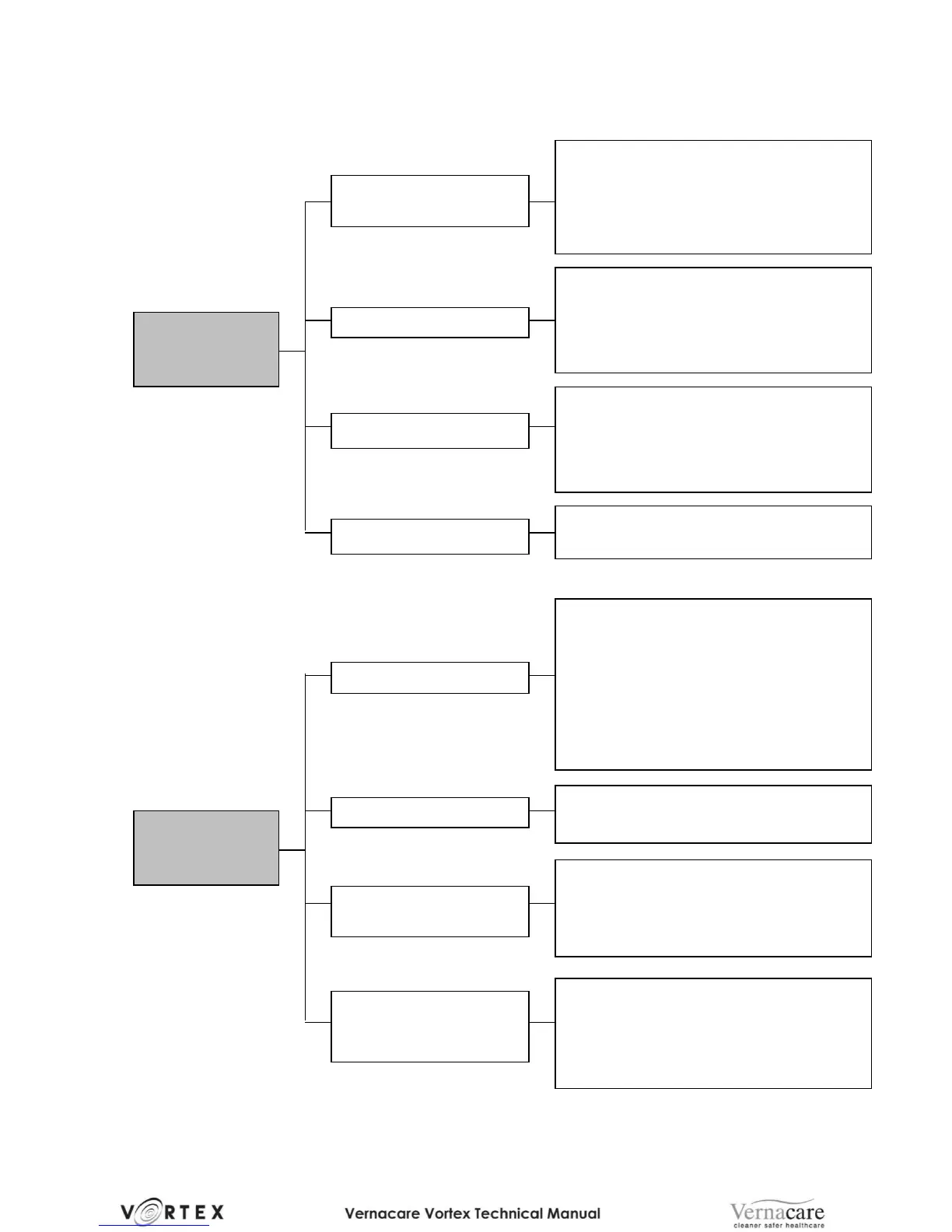

Pressure transducer not

operating.

Back pressure from

adjacent items in

Sluice room.

Hopper vent outlet blockage – Clean.

Vent pipe blockage – Clean.

Check the press switch operation –

Replace.

Check for water in the pressure switch

pipe – Clean & dry.

Check that there is no blockage in the

service drain – Clean.

Check that all equipment served by the

service drain is installed correctly –

Amend if necessary.

Loading...

Loading...