cuts due to sharp-edged chips. Never use flammable solvents or cleaning

agents or agents that generate noxious fumes!

Protect electrical components, such as motors, switches, switch boxes,

etc., against humidity when cleaning.

4. After the operation every day, eliminate all the chips and clean different

parts of the machine tool and apply machine tool oil to prevent rusting.

5. In order to maintain machining accuracy, take care of the center. The

surface of the machine tool for the chuck and the guideway and avoid

mechanical damage and wear due to improper guide.

6. If the damage is found, maintenance should be done immediately.

NOTES: Repair work may only be carried out by qualified personnel with

the corresponding mechanical and electrical knowledge.

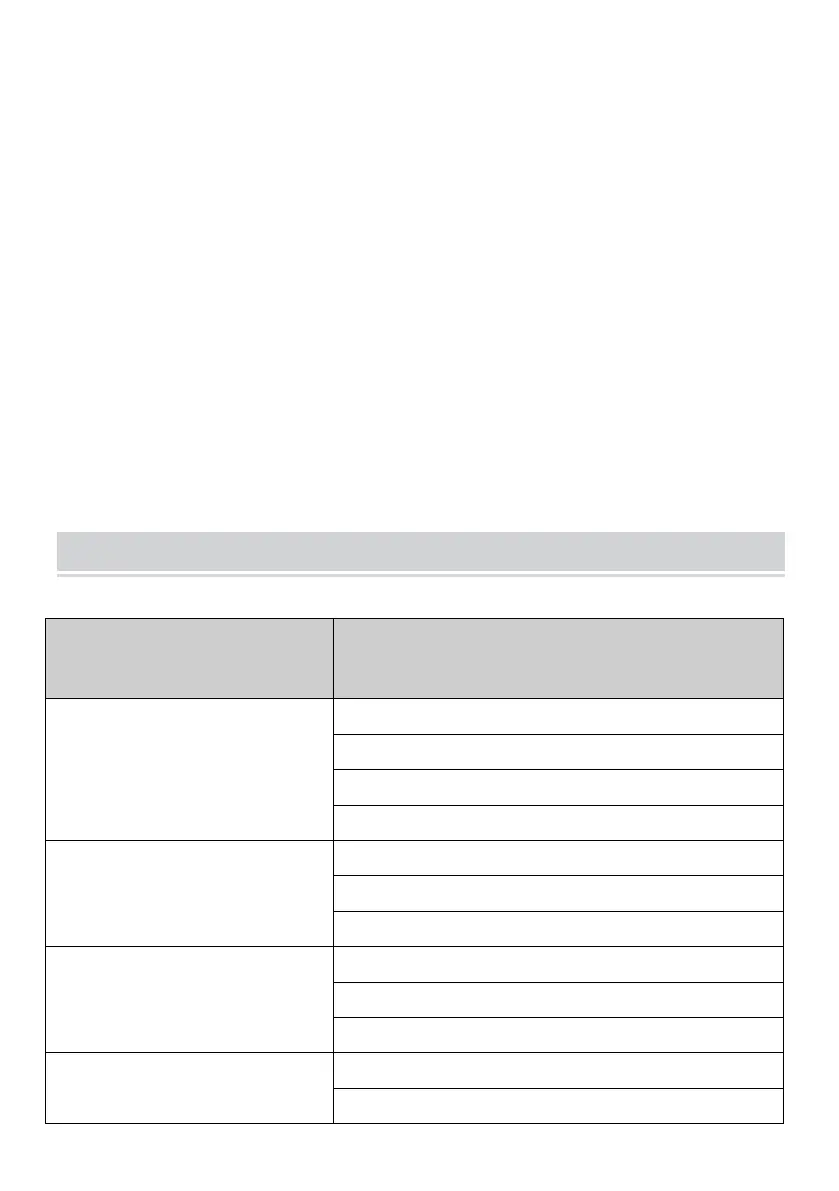

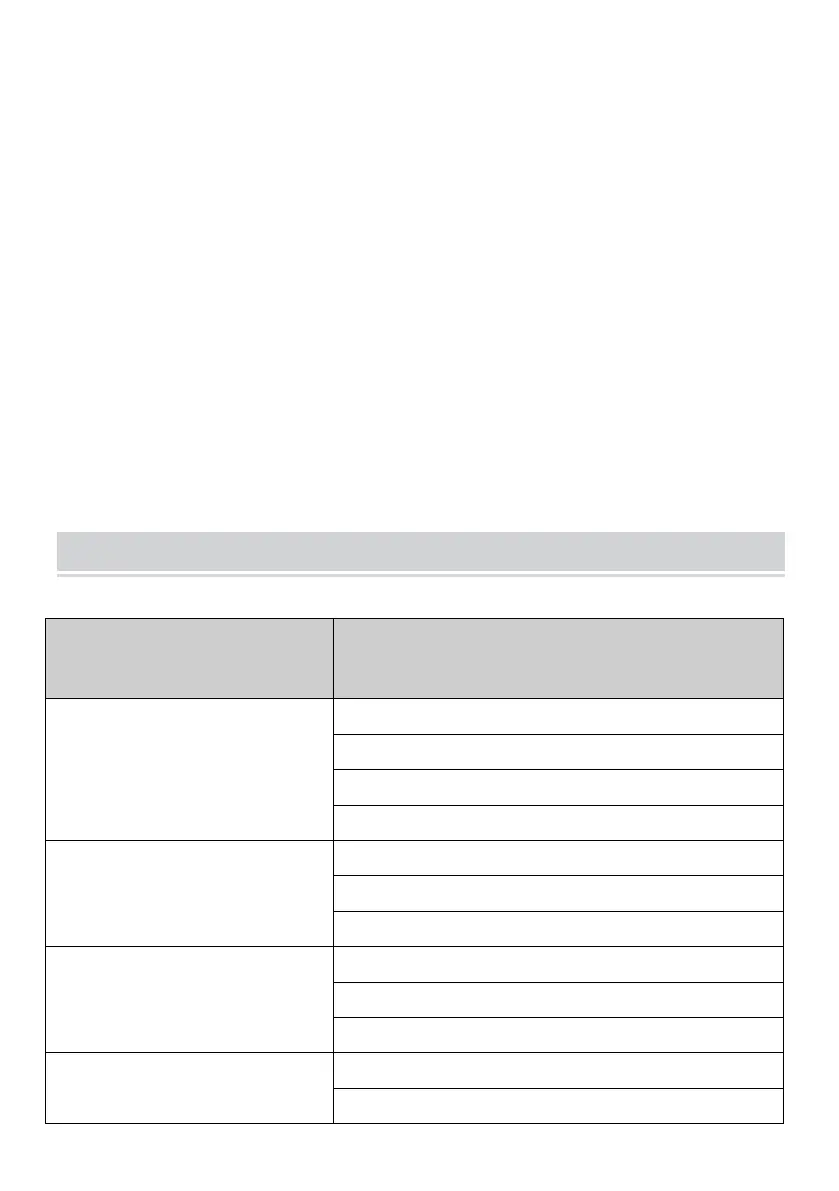

The workpiece’s surface is

too rough.

Re-sharpen the cutting tool.

Clamp the cutting tool with less overhang.

Increase the tool tip’s radius.

The cutting tool has a short

lifespan.

Reduce the cutting speed.

Lower the crossfeed distance.

Add more lubricant to the workpiece.

The cutting edge breaks off.

Increase the wedge angle.

Lubricate the workpiece uniformly.

Tighten the spindle bearing.

The cutting thread is wrong.

Adjust the cutting tool’s grinding angle.

Adjust the cutting tool’s pitch.

Loading...

Loading...