6.5 Opening & closing the multi-

purpose compartment

NOTICE

Damaging of the machine

when operating the multi-

purpose compartment

If you operate and/ or maintain the multi-purpose

compartment incorrectly, the machine may get

damaged.

Only manually open and/ or close the multi-purpose

compartment flap in case of an emergency. Oper-

ation: Executing jobs – on page46

Do not support yourself on the multi-purpose com-

partment flap. Do not put any objects onto the flap.

Check regularly if the area below the cooling liquid

tank is dry and remove leaked cooling liquid imme-

diately.

When you operate the blank changer with

DENTALCNC, the multi-purpose compartment

opens and closes automatically.

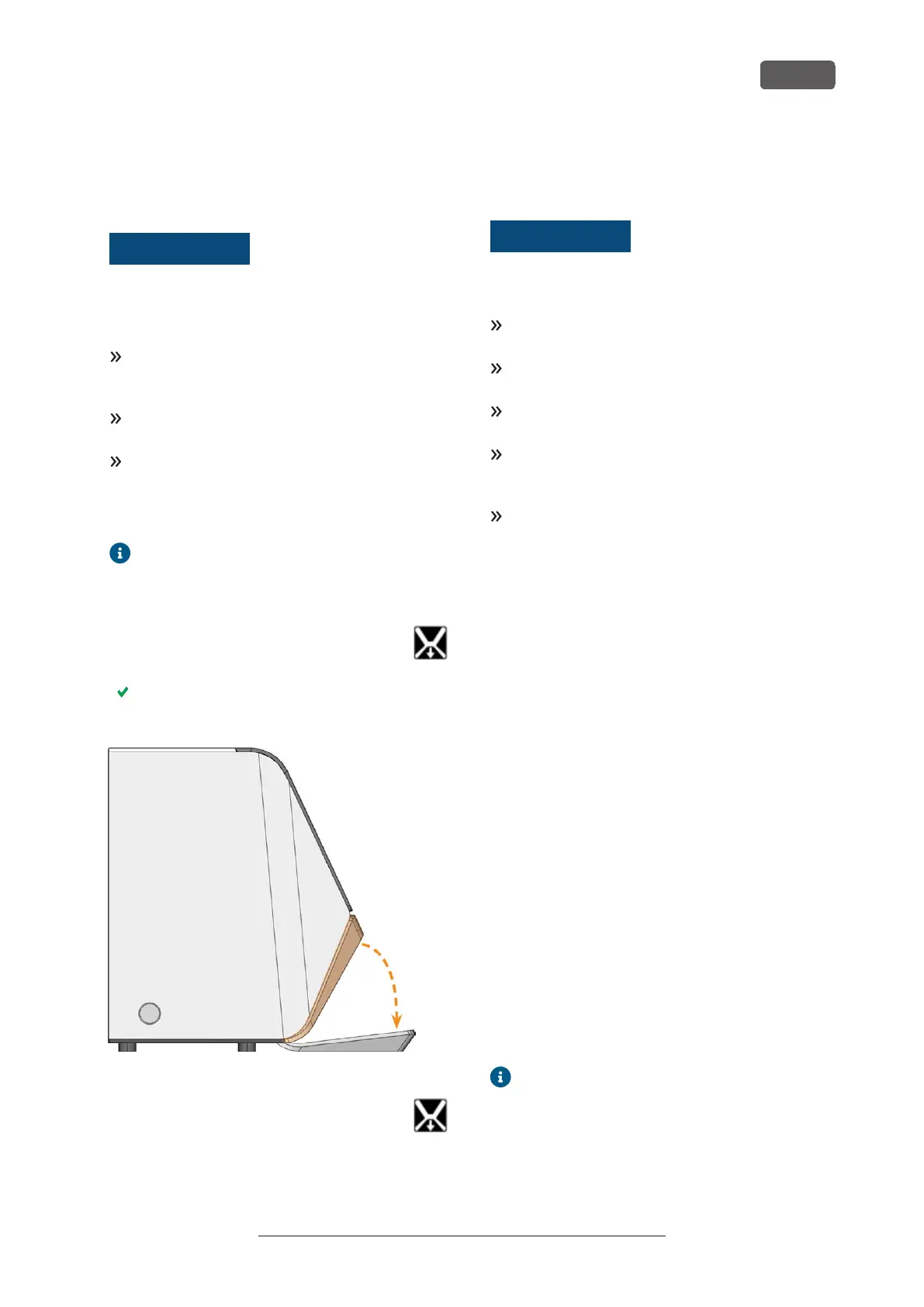

1. To open the multi-purpose compartment,

select the depicted icon in the Machining

view in DENTALCNC.

The multi-purpose compartment flap swings down-

wards.

FIG. 34 OPENING THE MULTI-PURPOSE COMPARTMENT

2. To close the multi-purpose compartment,

select the depicted icon in the Machining

view in DENTALCNC.

6.6 Exchanging the cooling liquid

and cleaning the tank

NOTICE

Damages caused by wet

machining with unsuitable

cooling liquid

Wet machining without suitable cooling liquid can

damage the machine, tools and blanks.

Before you execute a job, ensure that the cooling

liquid is clean and the liquid level is sufficient.

Only use cooling liquid that meets the requirements

listed below.

If you use a cooling lubricant: Only add the cooling

lubricant Tec Liquid Pro to the cooling liquid.

Exchange used cooling liquid according to the main-

tenance table. Clean the cooling liquid tank before

refilling it.

If you use a cleaning agent to clean the tank, ensure

that no residues of it remain in the tank.

The machine needs cooling liquid that meets the

following requirements:

n

Drinking water – for some blank types, you must

add cooling lubricant (see below)

n

No added chlorine

n

No distilled water

n

No carbonated water

Without sufficient cooling liquid in the tank, wet

machining is not possible. You can find the appropriate

interval in the maintenance table.Of course, you can

exchange the cooling liquid at any time.

You need to exchange the cooling liquid in the

following cases:

n

The change interval in the maintenance table has

been exceeded.

n

The cooling liquid is soiled.

n

In case of a strong odor from or a biofilm on the

cooling liquid.

n

If you use a cooling lubricant: The pH value is

below 9.

Every time you exchange the cooling liquid, you must

also clean the tank.

The cooling liquid tank is dishwasher-safe. If

you use a dishwasher, select a cleaning

program with a maximum temperature of 70 °C

(160 °F). To preserve the cooling liquid filter,

you can remove it and clean it by hand.

Before every job, you also have to check the strainer

basket and empty it if required.

R5 – Operation: Preparing jobs

EN 33

Original Operating Instructions:R5

Version: 12/16/2021

Loading...

Loading...