FIG. 60 REMOVING THE TOOL FROM THE COLLET CHUCK

9. Close the working chamber door.

10. Confirm the current message.

The following happens:

a. The collet chuck closes.

b. If your machine is equipped with an automatic

working chamber door, the door automatically

closes.

c. The spindle moves to its default position.

7.3 DirectClean Technology

The DirectClean Technology of the R5 improves the

cleanliness of the machine, especially when alternating

between wet and dry jobs. It consists of the following

processes:

n

Blowing off the blank with compressed air

n

Drying the working chamber with heated

compressed air

n

Discharging machining debris during machining

with the ionizer for suitable blank types

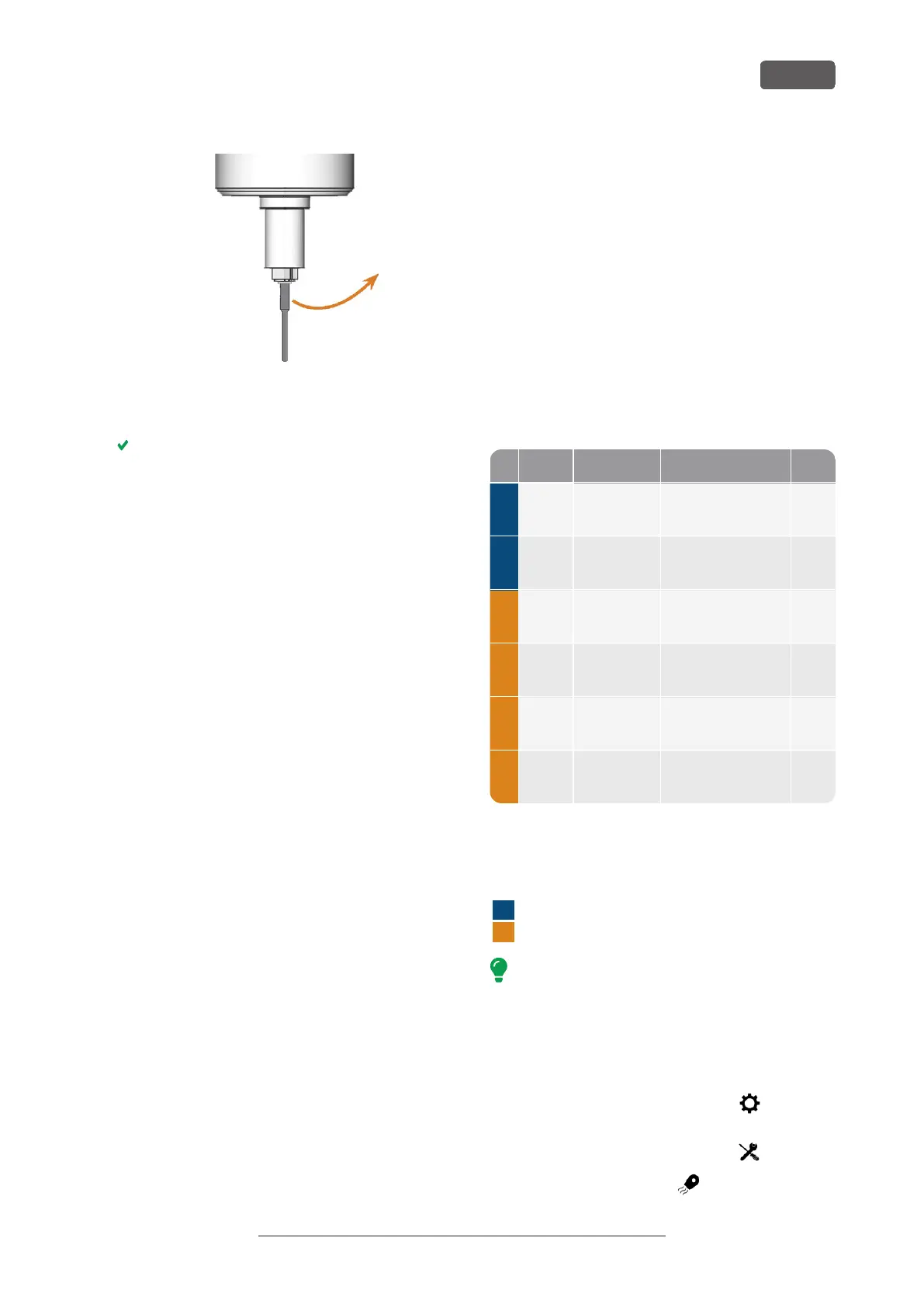

The blowing and drying process is triggered by the

sequence and type of jobs. You can find the corres-

ponding details in the table below.

Job followed by Program D

Dry job no job Blowing off the

blank

1

2

Wet

job

no job Drying 15

*

Dry job any job Blowing off the

blank

2

Wet

job

no job Drying 15

*

Wet

job

dry job Drying 15

Wet

job

wet job Drying 15

*

1

Can be deactivated in the DENTALCNC settings

*

Can be reduced to 2 minutes in the DENTALCNC settings

D Duration in minutes

Blank inserted into the working chamber

Blank(s) loaded from the blank magazine

To minimize the cleaning time, we recommend

executing all dry jobs before all wet jobs.

Manually starting the drying program

You can also start the drying program manually.

1. Open the DENTALCNC Application settings with the

following icon in the main iconbar:

2. Open the Machine maintenance view with the

following icon in the local iconbar:

3.

Select the following icon:

R5 – Operation: Executing jobs

EN 47

Original Operating Instructions:R5

Version: 12/16/2021

Loading...

Loading...