IIleTA

MAINTENANCE

Cont.

NOTE

Friction pads must be replaced when the

inside of cam lever touches the housing.

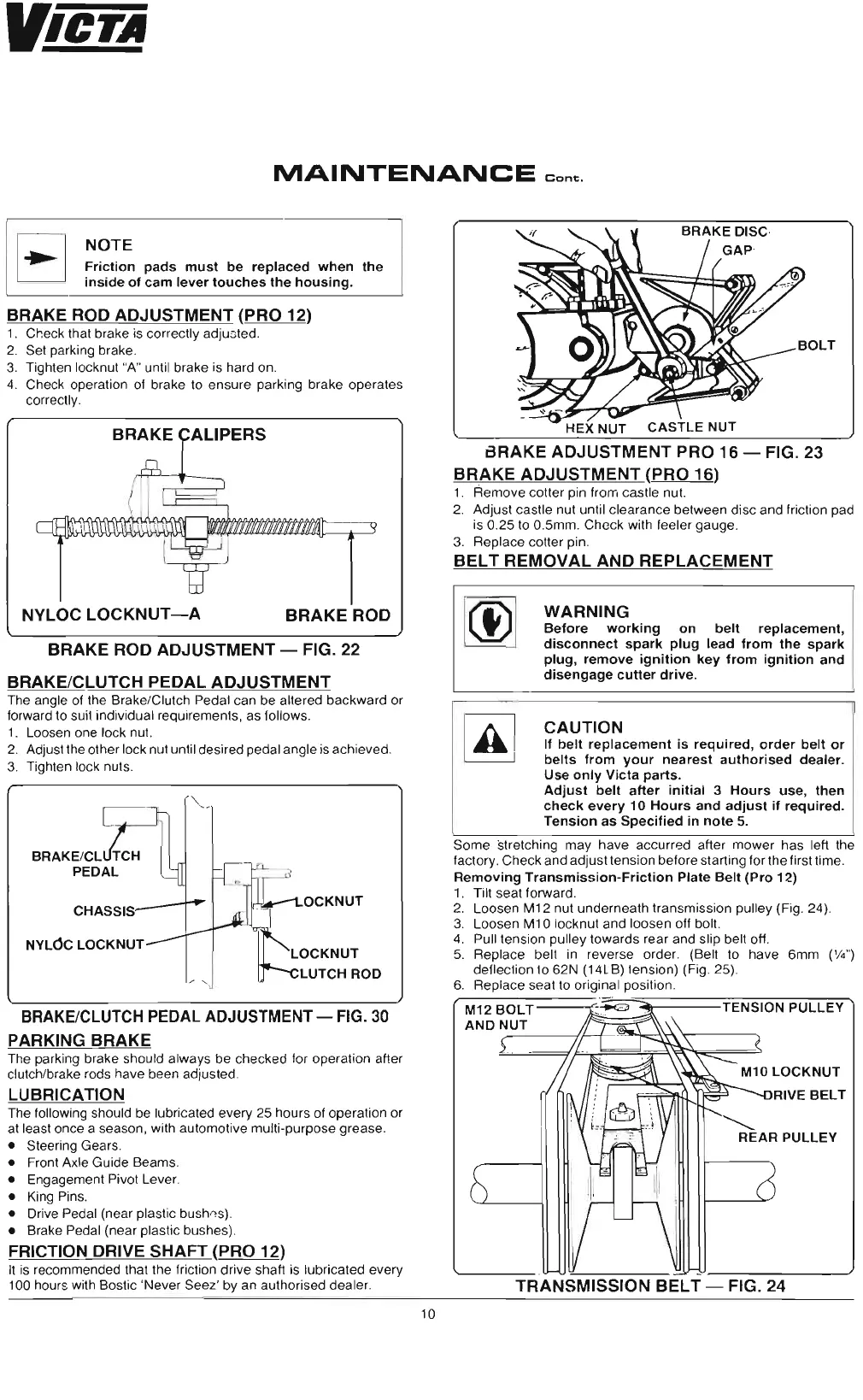

BRAKE ROD ADJUSTMENT (PRO 12)

1. Check that brake is correctly adjusted.

2. Set park ing brake .

3. Tighten locknut "A" until brake is hard on.

4. Check operat ion of brake to ensure parking brake operates

correctly.

NYLOC

LOCKNUT-A

BRAKE ROD

BRAKE ROD ADJUSTMENT - FIG.

22

BRAKE/CLUTCH PEDAL ADJUSTMENT

The angle of the Brake/Clutch Pedal can be altered backward or

forward to suit individual requirements , as follows.

1. Loosen one lock nut.

2. Adjust the other lock nut until desired pedal angle is achieved.

3. Tighten lock nuts.

BRAKE/CL TCH

PEDAL

CHASSIS

NYLdc

LOCKNUT

-

~

.

1

~

O

C

K

N U T

I

J~

I

~LOCKNUT

IhLUTCHROD

BRAKE

/CLUTCH

PEDAL

ADJUSTMENT

- FIG. 30

PARKING BRAKE

The parking brake should always be checked for operation after

clutch/brake rods have been adjusted.

LUBRICATION

The following should be lubricated every 25

hour

s of operation or

at least once a season, with automotive multi-purpose

grease

.

• Steering Gears .

• Front Axle Guide Beams.

• Engagement Pivot Lever.

• King Pins.

• Drive Pedal (near plasti c bush os),

• Brake Pedal (near plasti c bushes).

FRICTION DRIVE SHAFT (PRO 12)

It is recommended that the friction drive shaft is lubricated every

100 hours with Bostic 'Never Seez ' by an authorised dea ler.

BRAKE ADJUSTMENT PRO 16 - FIG. 23

BRAKE ADJUSTMENT (PRO 16)

1. Remove cotter pin from cas tle nut.

2. Adjust castle nut until clearance between disc and friction pad

is 0.25 to

0.5mm

.

Check

with feeler gauge .

3. Replace cotter pin.

BELT

REMOVAL

AND

REPLACEMENT

m

WARNING

Before

working

on belt replacement,

disconnect spark plug lead from the spark

plug, remove ignition key from ignition and

disengage cutter drive.

CAUTION

If belt replacement is required, order belt or

~

belts from your nearest authorised dealer.

Use only Victa parts .

Adjust belt after initial 3 Hours use, then

check every 10 Hours and adjust if required.

Tension as Specified in note 5.

Some

stretching may have accurred after

mower

has left the

factory.

Check

and adjust tension before sta rting for the first time.

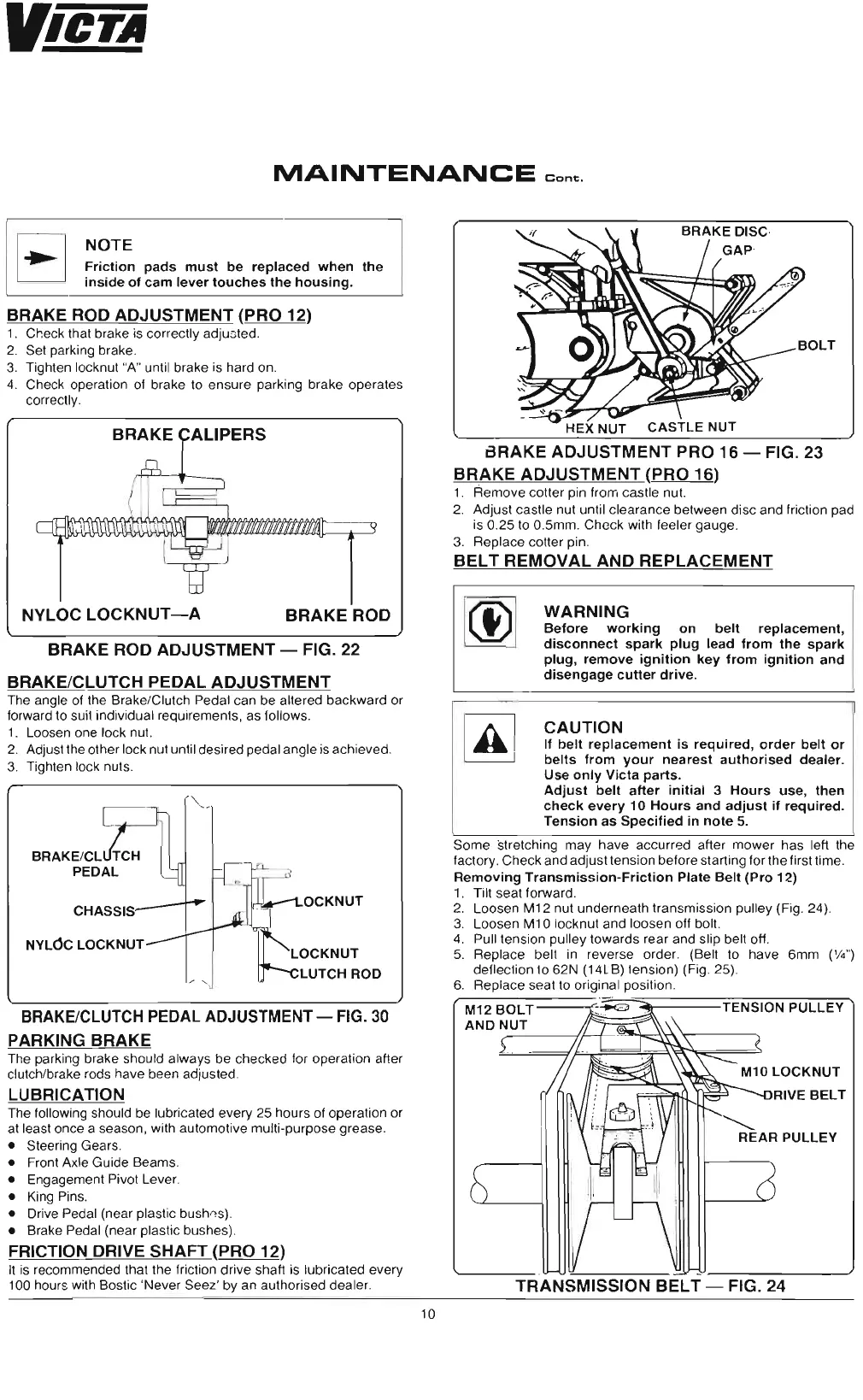

Removing Transmission-Friction Plate Belt (Pro 12)

1. Tilt seat forward.

2. Loosen M12 nut underneath tran smission pulley (Fig. 24).

3. Loos en M10 locknut and loosen off bolt.

4. Pull tension pulley towards rear and slip belt off.

5. Repla ce belt in reverse order. (Belt to have 6mm ('14')

deflection to 62N (14LB) tension) (Fig. 25).

6. Replace seat to original position.

~~==~~jp'j"j'j'""i'FV1

TENSION PULLEY

<,

REAR PULLEY

-

TRANSMISSION BELT - FIG. 24

10

Loading...

Loading...