",eTA

MAINTENANCE

[PRO

12]

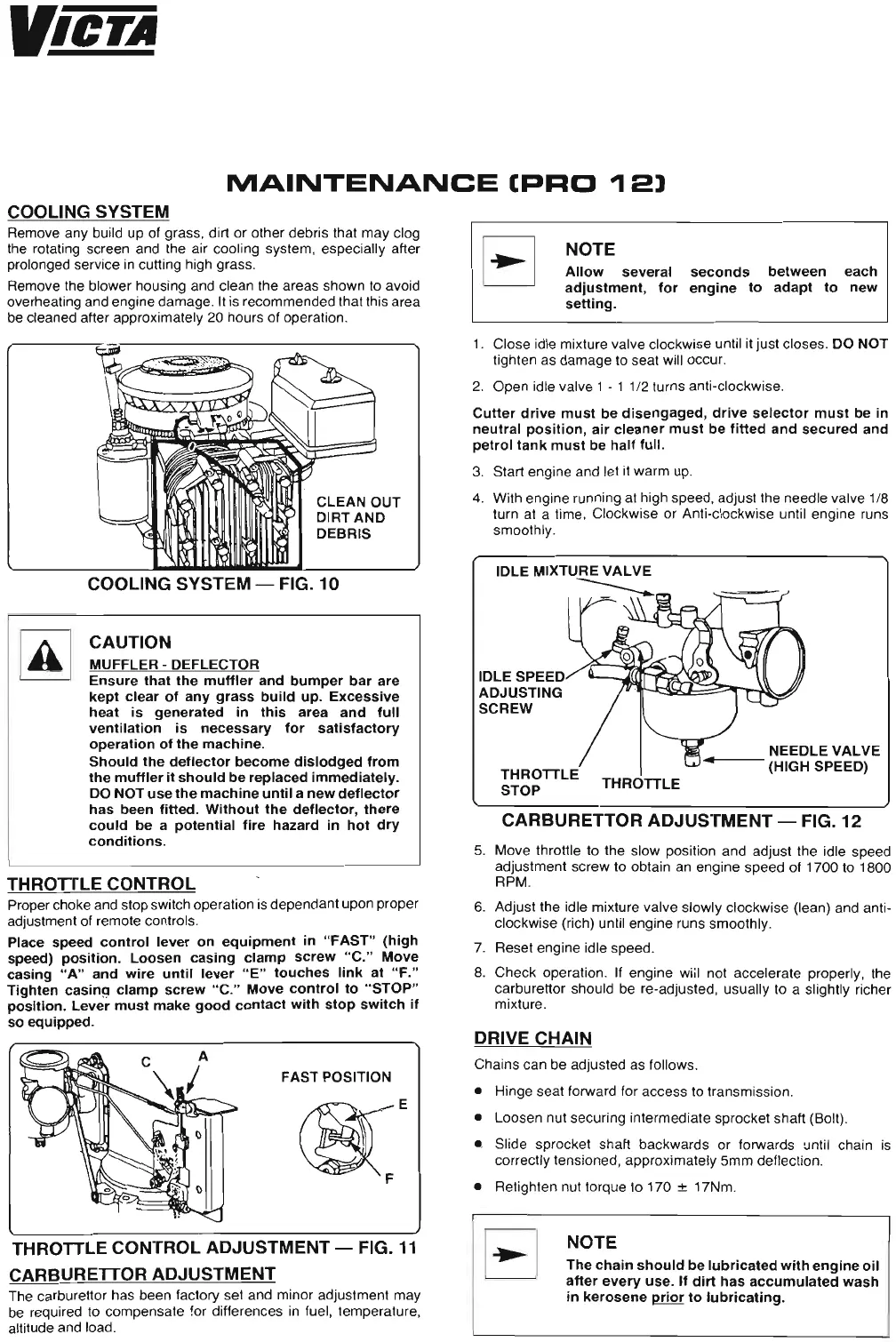

COOLING SYSTEM

Remove any build up of grass , dirt or other debris that may clog

the rotating screen and the air cooling system, especially after

prolonged service in cutting high grass .

Remove the blower housing and clean the areas shown to avoid

overheating and engine damage.

It is recommended that this area

be cleaned after approximately 20 hours of operation.

COOLING SYSTEM - FIG. 10

CAUTION

MUFFLER - DEFLECTOR

Ensure

that

the

muffler

and

bumper

bar

are

kept

clear

of

any

grass

build

up.

Excessive

heat

is

generated

in

this

area

and

full

ventilation

is

necessary

for

satisfactory

operation

of

the

machine.

Should

the

deflector

become

dislodged

from

the

muffler

it

should

be replaced

immediately.

DO NOT

use

the

machine

until

a

new

deflector

has been

fitted.

Without

the

deflector,

there

could

be a

potential

fire

hazard in

hot

dry

conditions.

THRorrLE

CONTROL

Proper choke and stop switch operation is dependant upon proper

adjustment of remote controls .

Place speed

control

lever

on

equipment

in

"FAST"

(high

speed)

position.

Loosen

casing

clamp

screw

"C."

Move

casing

"A"

and

wire

until

lever

" E"

touches

link

at

"F."

Tighten

casing

clamp

screw

"C."

Move

control

to

"STOP"

position.

Lever

must

make

good

contact

with

stop

switch

if

so

equipped

.

FAST POSITION

~E

F

THROTTLE CONTROL ADJUSTMENT - FIG. 11

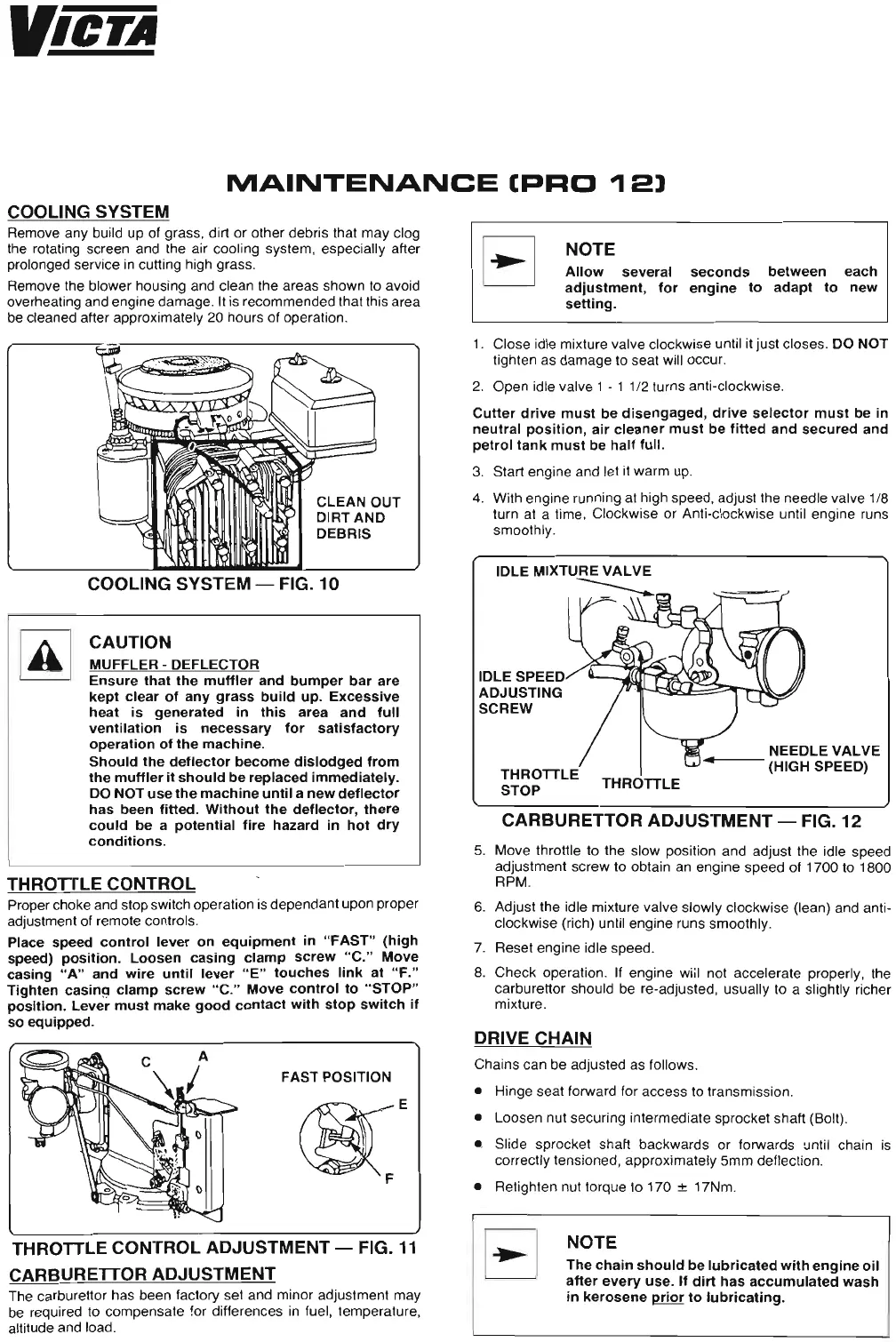

CARBURETTOR ADJUSTMENT

The carburettor has been factory set and minor adjustment may

be required to compensate for differences in fuel, temperature,

altitude and load.

EJ

NOTE

Allow

several

seconds

between

each

adjustment,

for

engine

to

adapt

to

new

setting.

1. Close idle mixture valve clockwise until it just closes . DO NOT

tighten as damage to seat will occur.

2. Open idle valve 1 - 1 1/2 turns anti-clockwise.

Cutter

drive

must

be

disengaged,

drive

selector

must

be in

neutral

position,

air

cleaner

must

be

fitted

and

secured

and

petrol

tank

must

be

half

full.

3. Start engine and let it warm up.

4. With engine running at high speed, adjust the needle valve 1/8

turn at a time, Clockwise or Anti-clockwise until engine runs

smoothly.

IDLE SPEED

ADJUSTING

SCREW

NEEDLE

VALVE

GJ·_--

(HIGH SPEED)

THROTTLE

CARBURETTOR ADJUSTMENT - FIG. 12

5. Move throttle to the slow position and adjust the idle speed

adjustment screw to obtain an engine speed of 1700 to 1800

RPM.

6. Adjust the idle mixture valve slowly clockwise (lean) and anti-

clockwise (rich) until engine runs smoothly.

7. Reset engine idle speed.

8. Check operation. If engine wiil not accelerate properly, the

carburettor should be re-adjusted, usually to a slightly richer

mixture.

DRIVE CHAIN

Chains can be adjusted as follows .

• Hinge seat forward for access to transmission.

• Loosen nut securing intermediate sprocket shaft (Bolt).

• Slide sprocket shaft backwards or forwards until chain is

correctly tensioned, approximately 5mm deflection.

• Retighten nut torque to 170

± 17Nm.

EJ

NOTE

The

chain

should

be

lubricated

with

engine

oil

after

every

use.

If

dirt

has

accumulated

wash

in

kerosene

prior

to

lubricating.

THROTTLE

STOP

Loading...

Loading...