CAUTION

DONOTusesolventsorabrasivesonornearthevalvebody•

seatring.

Failuretofollowthisinstructioncouldpreventtheclapper

fromsealing,resultinginimpropervalveoperationand/orvalve

leakage.

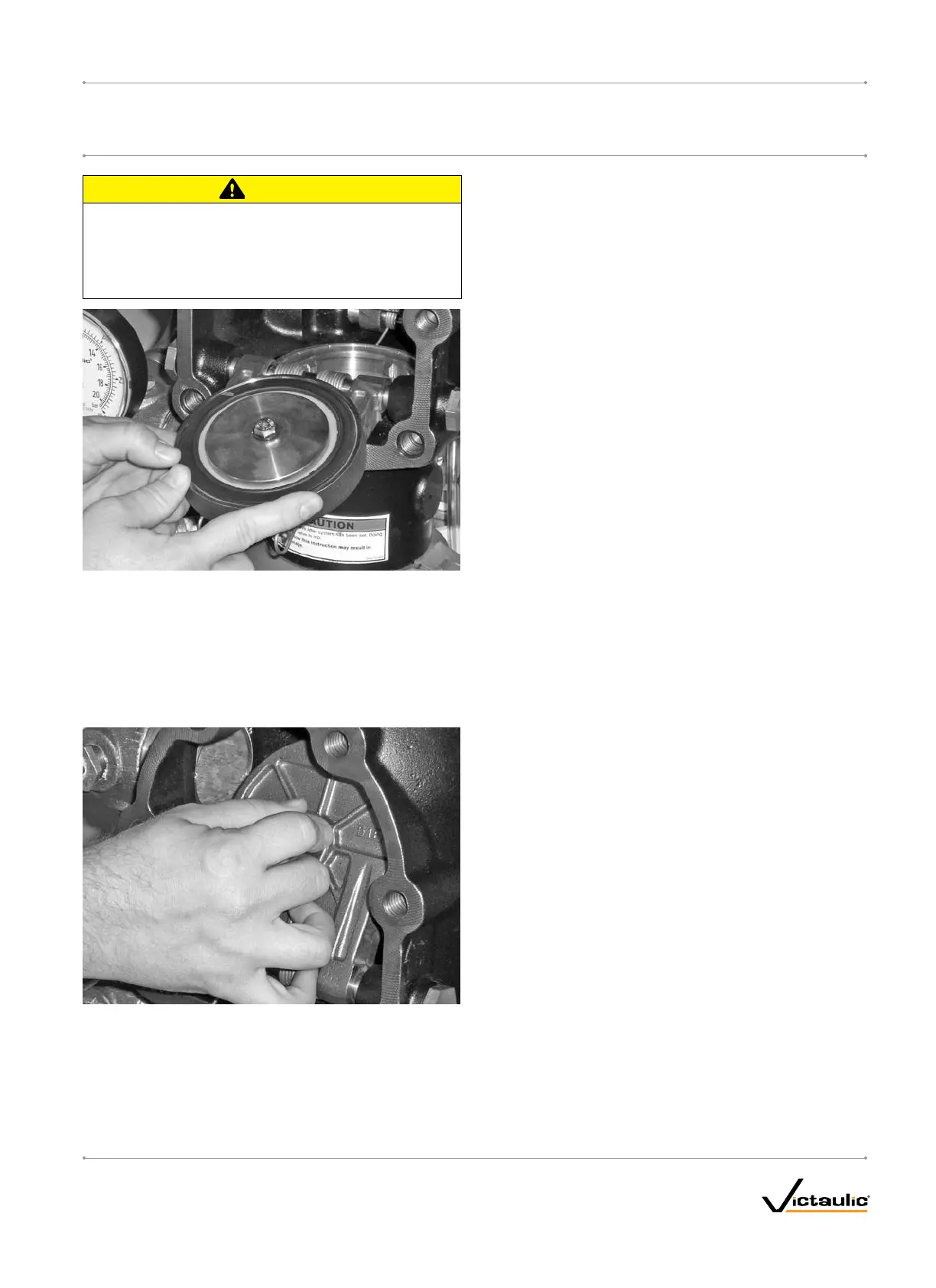

14. Rotate the clapper out of the valve body. Inspect the clapper seal

and seal-retaining ring. Wipe away any contaminants, dirt, and

mineral deposits. Clean out any holes that are plugged in the

valve-body seat ring. DONOTUSESOLVENTSORABRASIVES.

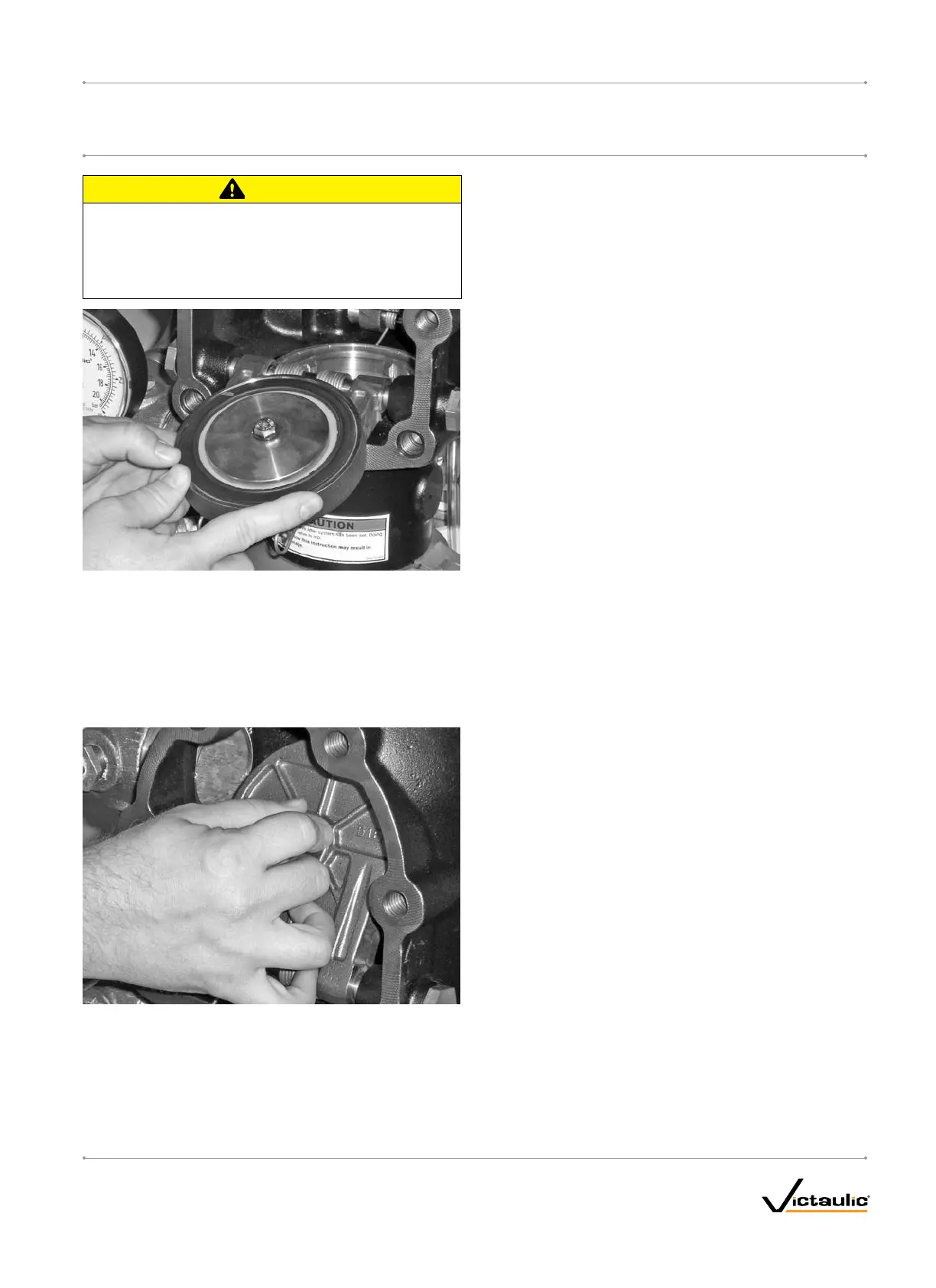

15. While the clapper is rotated out of the valve body, pull the latch

forward to inspect the diaphragm. If the diaphragm shows any

signs of wear or damage, replace it with a new, Victaulic-supplied

diaphragm. Refer to the “Removing and Replacing the Diaphragm

Assembly” section.

16. Inspect the clapper for freedom of movement and physical

damage. Replace any damaged or worn parts by following the

applicable instructions in the “Maintenance” section.

17. Re-install the cover plate by following the “Installing the Cover

Plate Gasket and Cover Plate” section.

18. Place the system back in service by following the “Placing the

System in Service” section.

I-768_31

FireLockNXT™DryValve

SERIES768

I-768INSTALLATION,MAINTENANCE,ANDTESTINGMANUAL

www.victaulic.com

VICTAULIC IS A REGISTERED TRADEMARK OF VICTAULIC COMPANY. © 2007 VICTAULIC COMPANY. ALL RIGHTS RESERVED. PRINTED IN THE USA.

REV_D

Loading...

Loading...