Checking the static and supply pressure

Danger

CO build-up as a result of an incorrect burner setup can have serious

health implications.

Carry out a CO test prior to and after work on gas equipment.

Operation with LPG

Flush the LPG tank twice during com-

missioning/replacement. Thoroughly

vent the tank and gas supply lines

after flushing.

1. Close the gas shut-off valve.

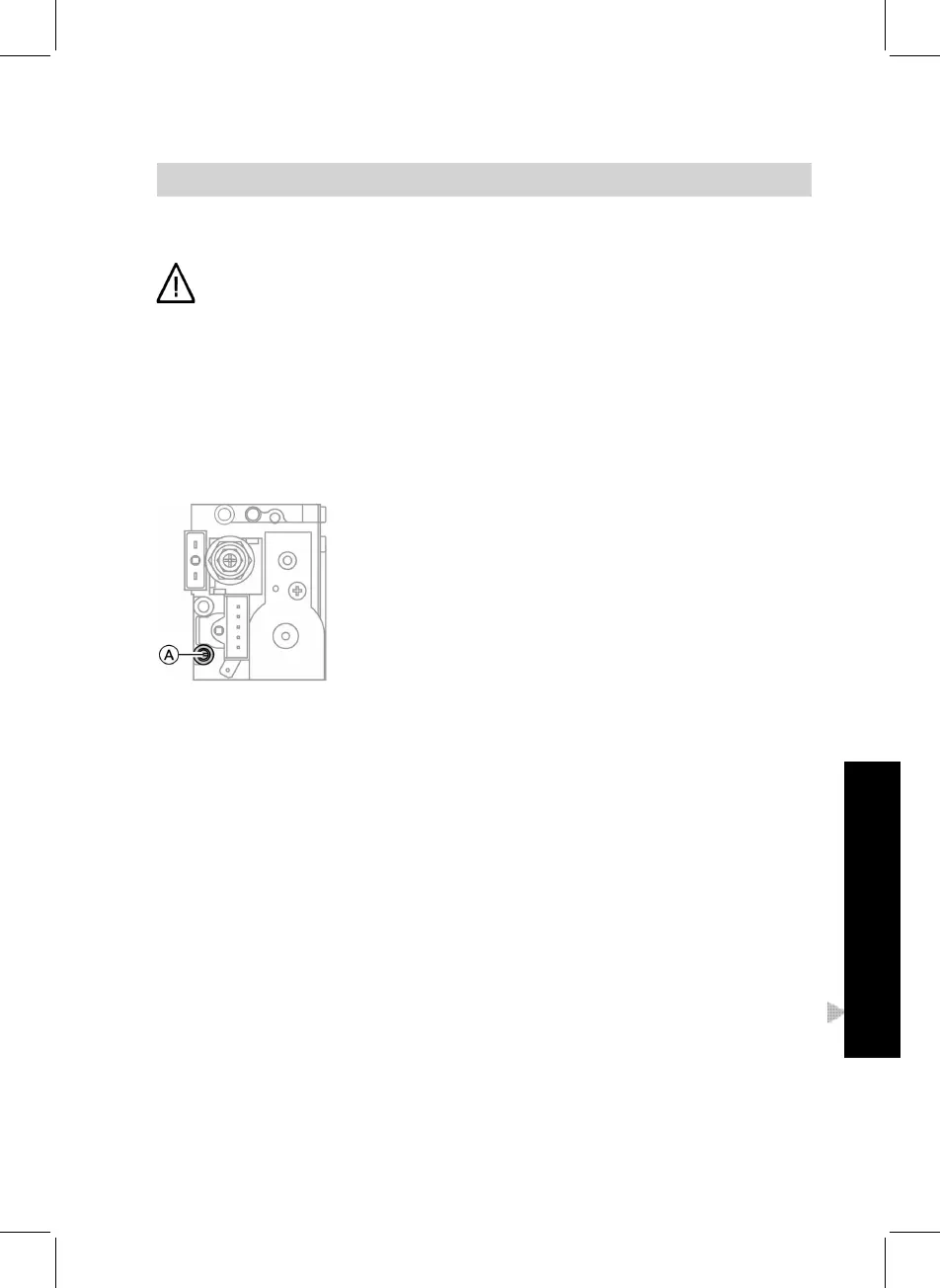

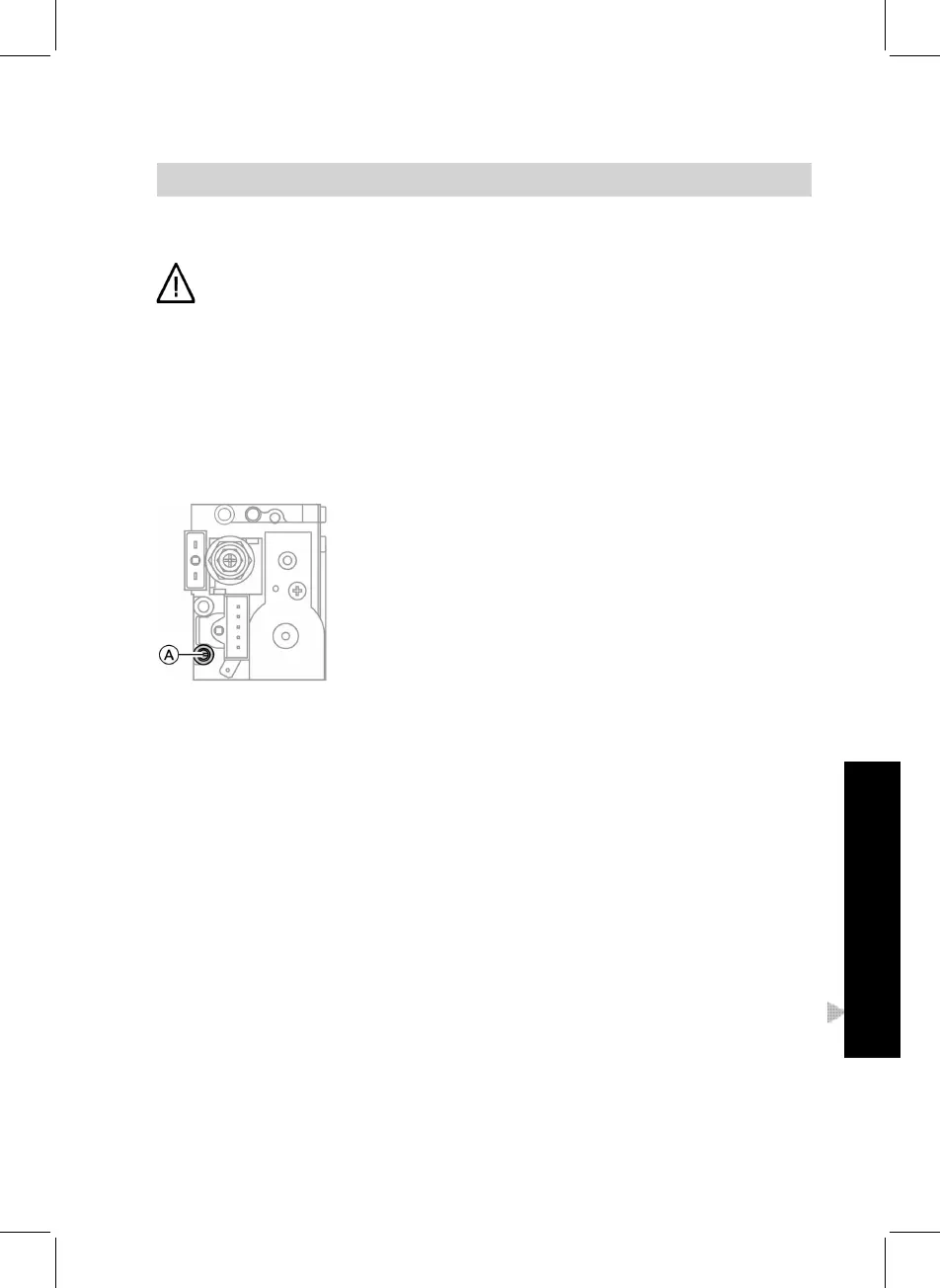

2. Undo the screw inside test connec-

tor A at the gas train, but do not

remove it, and connect the pres-

sure gauge.

3. Open the gas shut-off valve.

4. Measure the static pressure and

record it in the service report.

Set value: max. 57.5 mbar

5. Start the boiler.

Note

During commissioning, the boiler

can enter a fault state because of

airlocks in the gas pipe. After

approx. 5 s press "E RESET" to

reset the burner.

6. Check the supply (flow) pressure.

Set value:

&

Natural gas: 20 mbar

&

LPG: 50 mbar

Note

Use suitable test equipment with a

resolution of at least 0.1 mbar to

measure the supply pressure.

7. Record the actual value in the ser-

vice report.

Take the action shown in the table.

8. Switch OFF the system at the con-

trol unit (the boiler shuts down),

close the gas shut-off valve,

remove the pressure gauge and

close test connector A with the

screw.

Loading...

Loading...