9. Test the nozzle pressure at the

lower rated output. In case of

deviations from the value

shown in the table below, adjust

the nozzle pressure for the lower

rated output using cross-head

screw D. Hold screw C (SW 10)

to counter the torque applied.

10. Snap cap B into place.

11. Check the setting values and

record them in the service report.

12. Press d.

Operation with the lower output is

terminated.

13. Switch OFF the system at the

control unit (the boiler shuts

down), close the gas shut-off

valve, remove the pressure gauge

and close test connector A with

the screw.

14. Open the gas shut-off valve and

start up the boiler.

Danger

Gas escaping from the test

port leads to a risk of

explosion.

Check the test connector

for soundness.

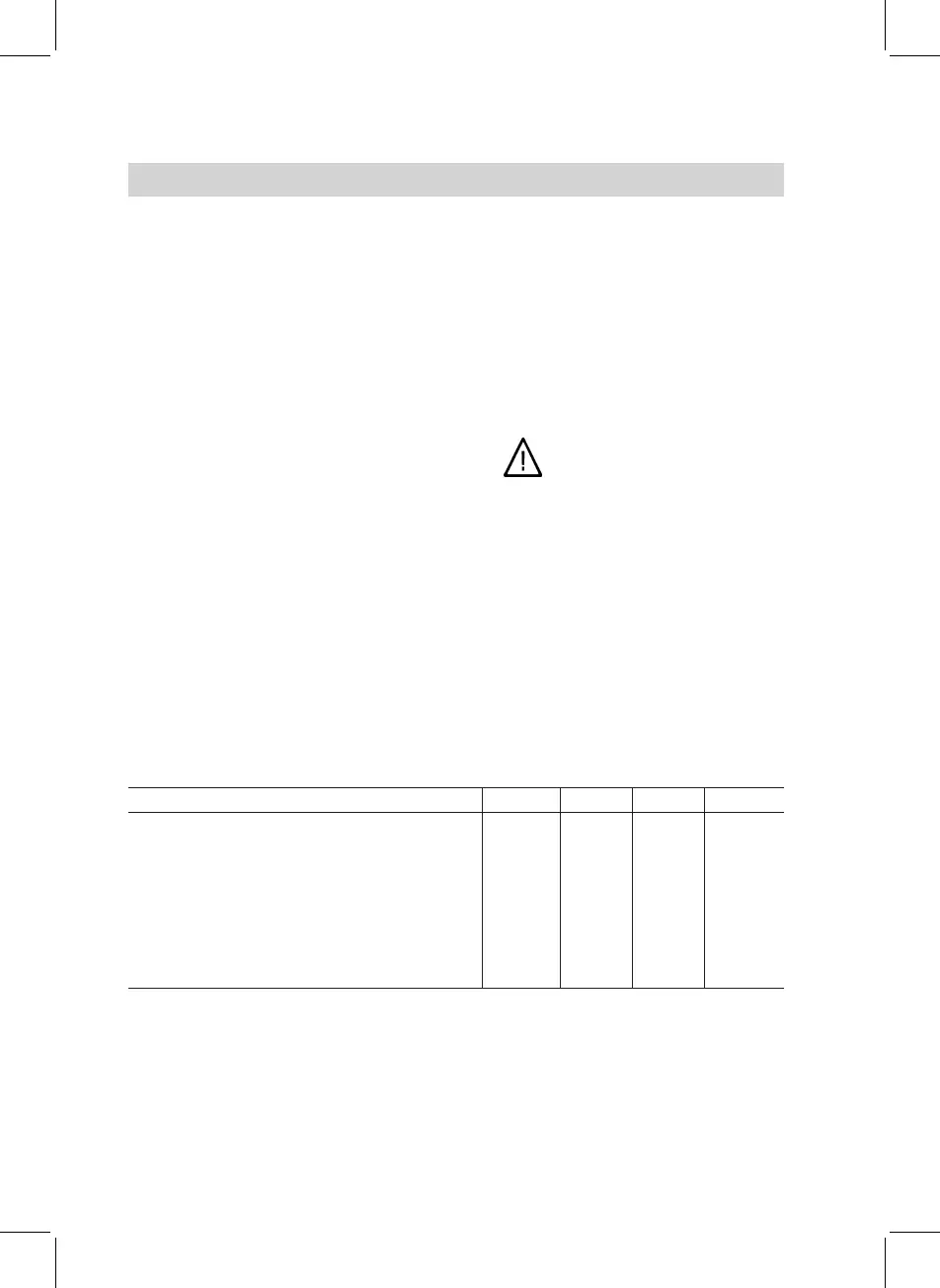

Note

The values in the nozzle pressure table apply to the following ambient condi-

tions:

&

Air pressure: 1013.25 mbar

&

Temperature: 15 °C

Wobbe index see page 23.

Nozzle pressure table

Output kW 10.5 24

29

*

1

Nozzle pressure

Gas Supply pres-

sure in mbar

Nozzle 7

in mm

Natural

gas E

20 1.25 mbar 2.0 10.2 15.1

Natural

gas LL

20 1.40 mbar 2.0 10.2 14.7

LPG 50 0.89 mbar 3.3 14.8 22.6

Setting the maximum output

You can limit the maximum output for heating operation. The limit is set via the

modulation range.

Loading...

Loading...