7602040

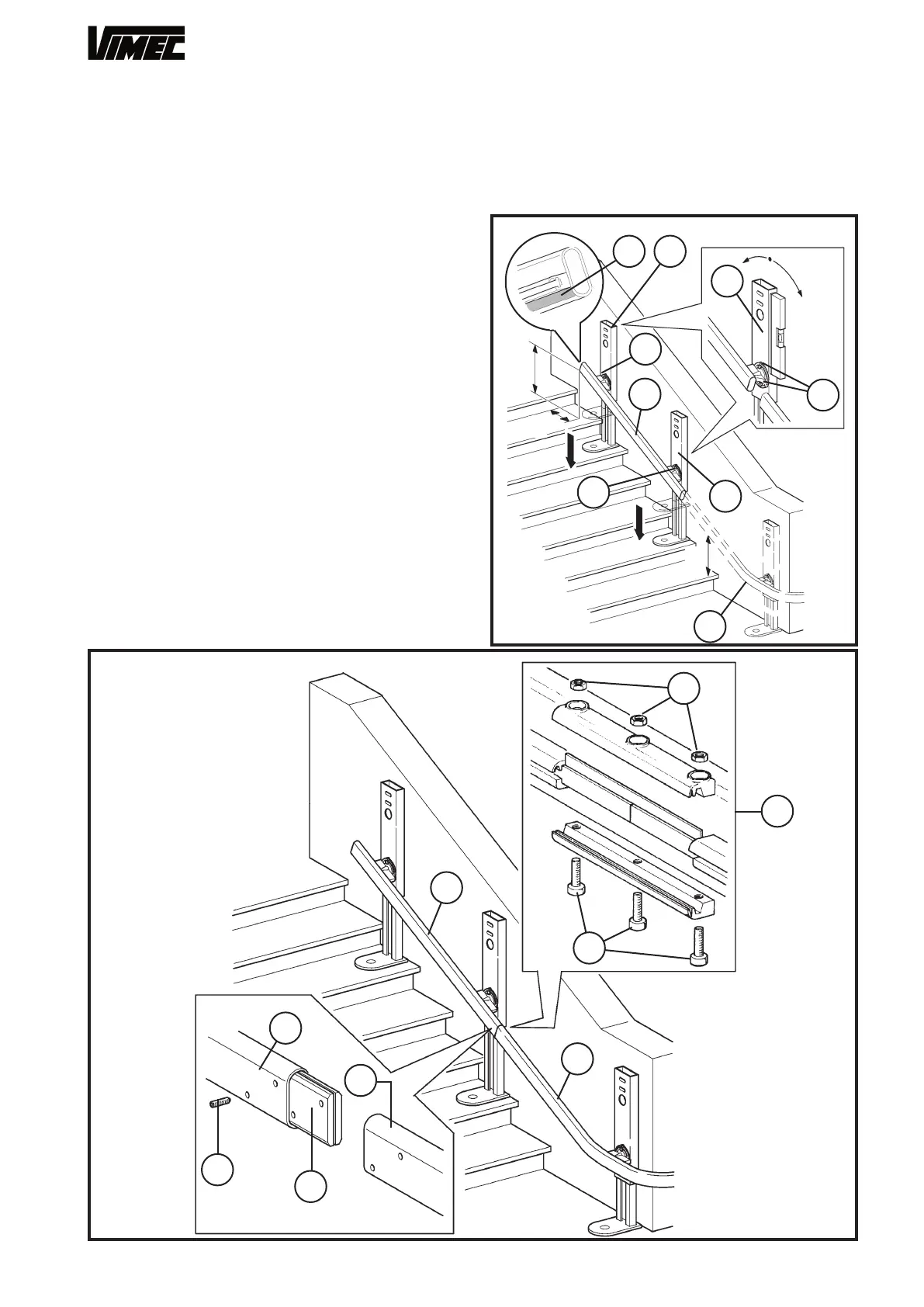

- Set the bend connection fixtures perfectly vertical

(Fig. 7) and tighten both the fixing screws once adjust-

ment is complete (Fig. 7/a).

N.B.: Check that the part of the lower rail (Fig. 8/g)

on which the brushes operate is clean, and remove

any dirt if necessary.

WARNING: The rail fixing screws (Fig. 7/a) must be

tightened to a torque of 9-10 daNm.

- Use the assembly markings (Fig. 3/b) to identify the

section of rail with feet (Fig. 8/a) to be placed just

above the bend just installed (Fig. 8/b).

- Position the rail correctly for installation (Fig. 8/a),

referring to the dimensions shown in the installation

drawing (example Fig. 5), extract the feet and lightly

tighten just one bolt (Fig. 8/c) for each connection

fixture (Fig. 8/d).

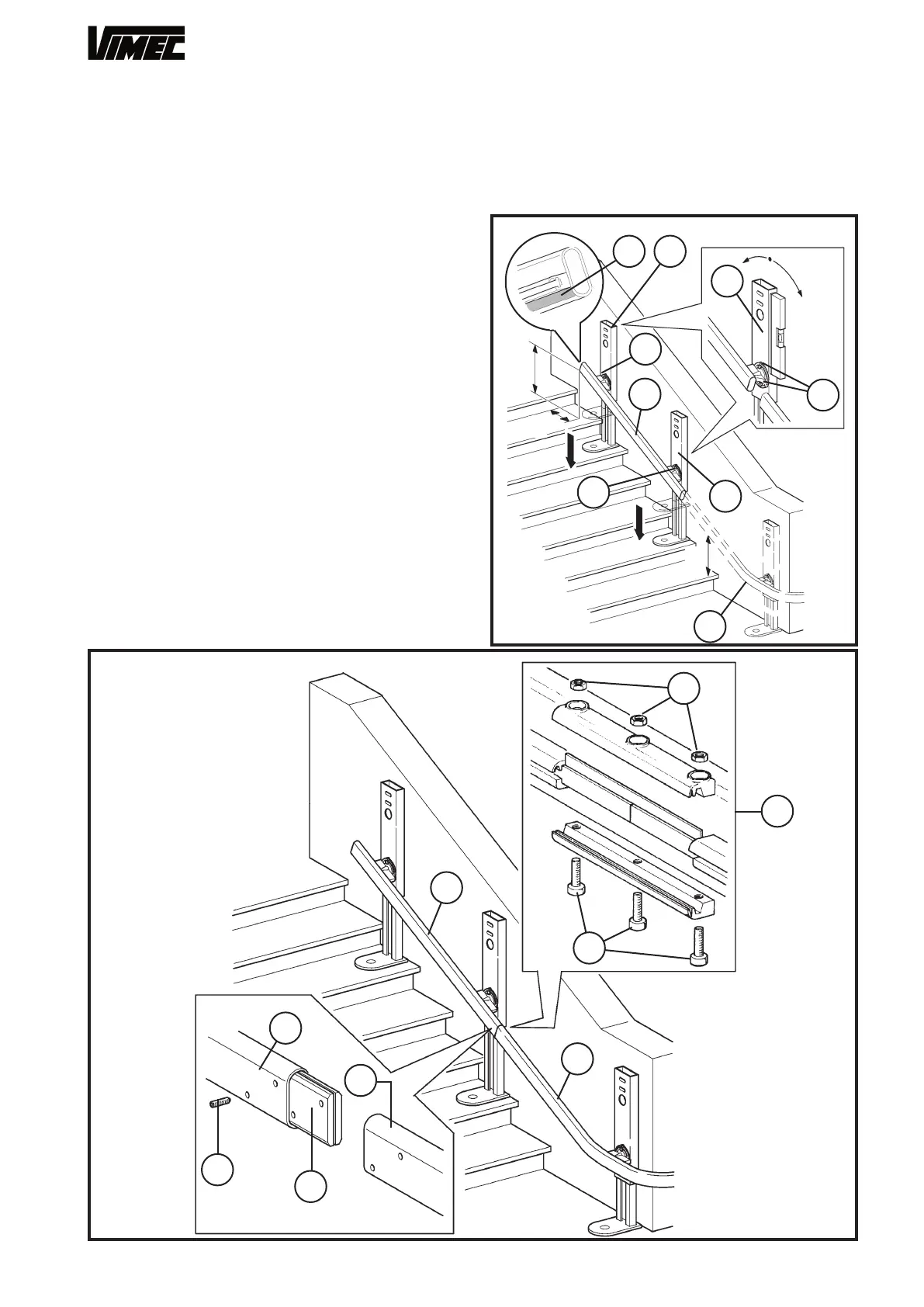

- Fit the joint plates (Fig. 9/e) into the tubular rail

(Fig. 9/ a) and lightly tighten the first 2 stud bolts

(Fig. 9/f).

- Place the next section of rail working downwards

(Fig. 9/b) in position, fit the other stud bolts and tighten

to a torque of 4-5 daNm after checking that the tubular

rails are correctly aligned and there is no gap between

the rail sections. Fit the busbar connection joint as

shown (Fig. 9/d) after checking that the components

are clean.

- Following the procedure already used for the bend,

set the connection fixtures (Fig. 8/e) perfectly vertical

and tighten both the fixing screws once adjustment is

complete (Fig. 8/f).

- Install all the sections of rail except the last one as

just described, down to the bottom of the staircase.

FIG.8

FIG.9

± 1°

max

19

C

D

A

e

f

d

a

b

c

d

c

g

h

g

d

c

c

e

b

f

a

± 1°

max

Loading...

Loading...