7602040

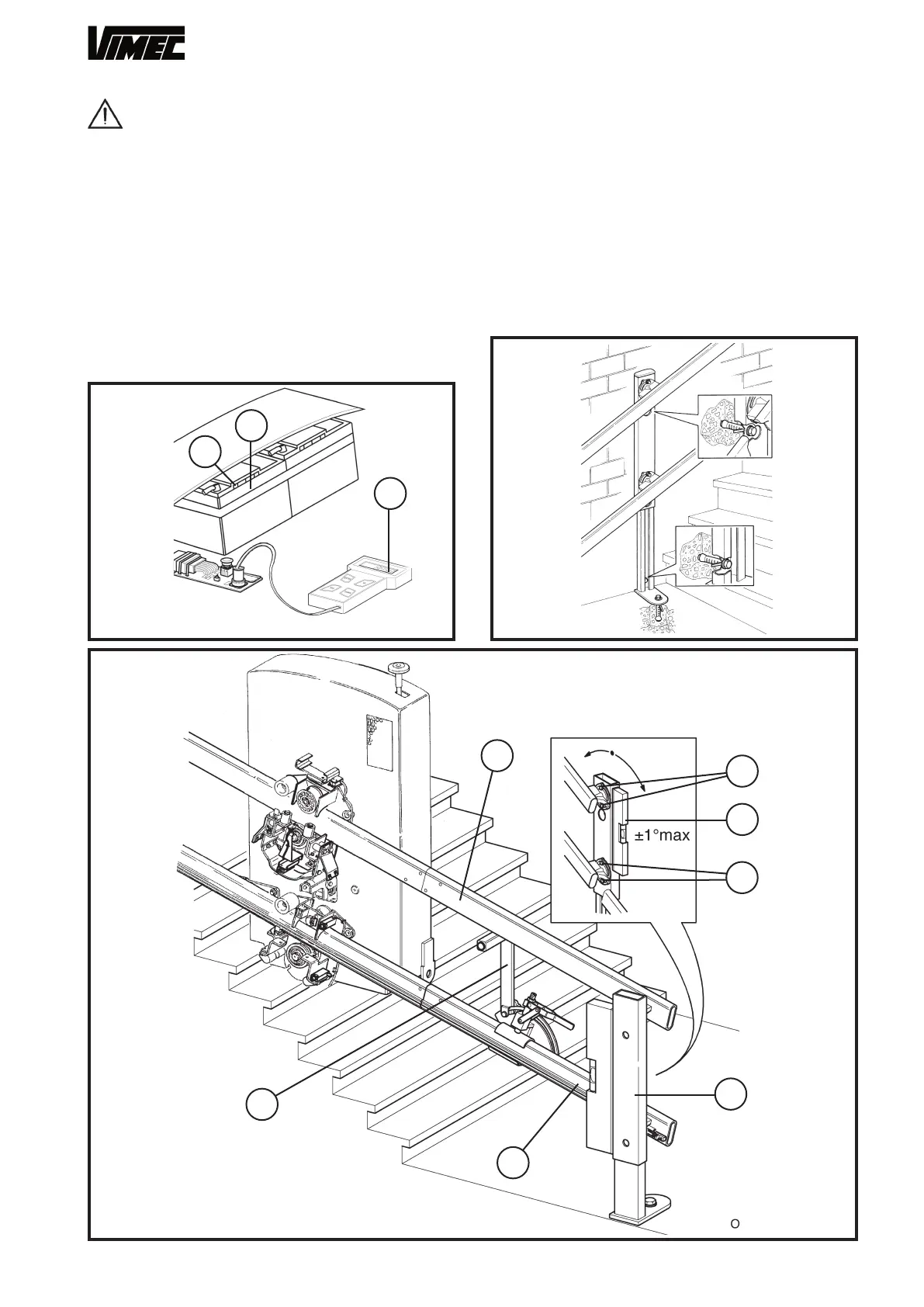

FIG.29

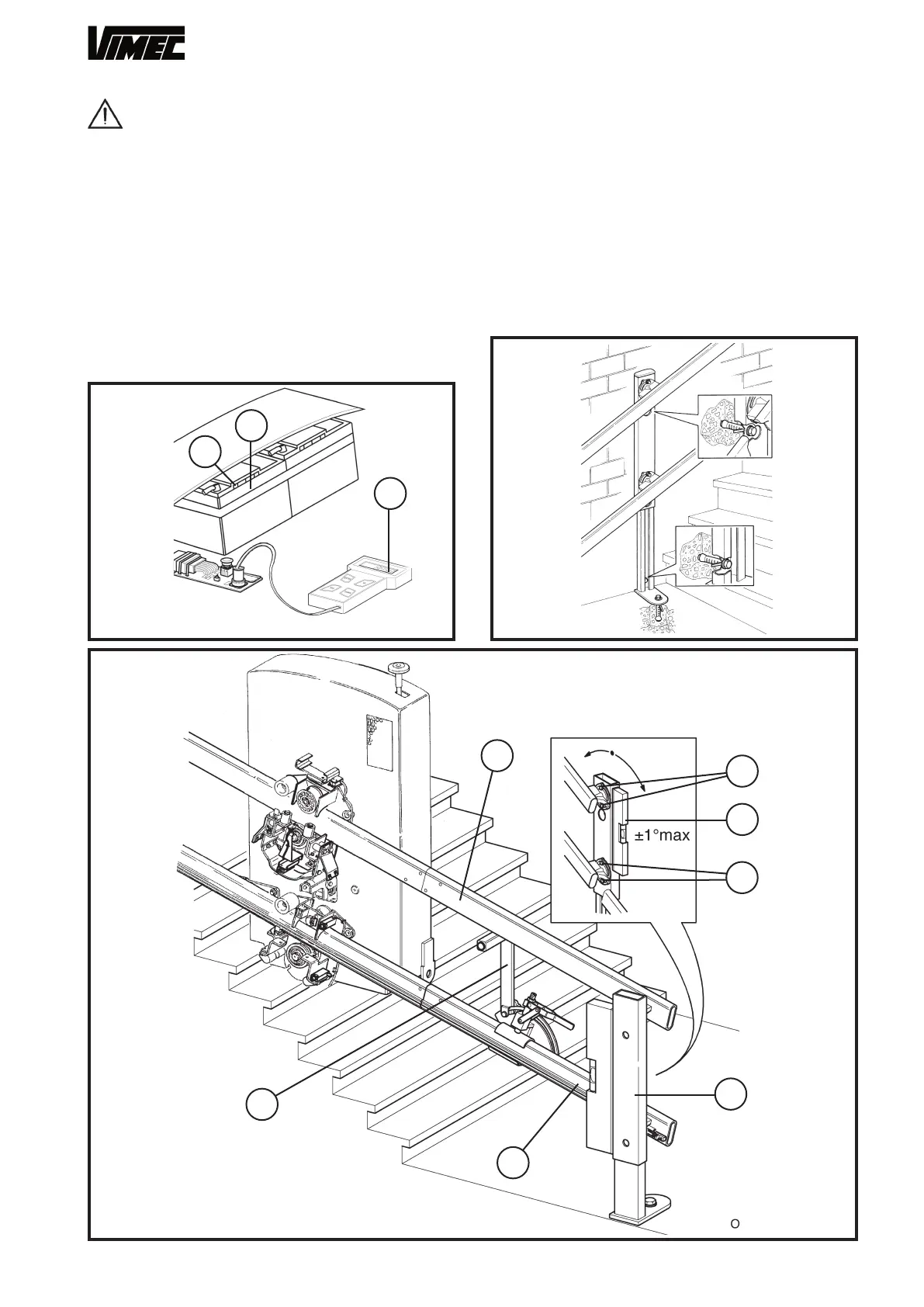

FIG.30

FIG.31

N.B.

:

Move the lift up to the 1st rigid connection and if it

is not horizontal, screw down the M10x30 screw (Fig.

15/a) with washer (Fig. 15/b) onto the clutch assembly

to release the upper carriage from the clutch assembly.

The gap is correct when the clutch assembly cam is

about 2 mm from the carriage (Fig. 15/c).

- Move the lift up a short way to allow it to settle back

into position.

- Undo the screw (Fig. 15/a) and its washer (Fig. 15/b)

to re-engage the clutch plate assembly with the car-

riage.

WARNING: all safety devices are deac-

tivated (the operator is responsible for ensuring

safety).

-

Use the UP and DOWN controls on the control panel

(Fig. 29/a) to bring the structure, complete with car-

riage, to the chosen floor, in order to continue as-

sembly operations in complete safety.

- Fit the spacer (Fig. 30/g) between the rails and install

the connection/foot (Fig. 30/a).

- After setting the rail at the correct distance (Fig. 30/b

– Fig. 30/c) using the spacer (Fig. 30/g), and after

checking that the components are vertical (Fig. 30/a)

tighten the screws firmly (Fig. 30/e and Fig. 30/f).

26

c

b

a

c

f

d

e

g

b

a

Loading...

Loading...