32

Maintenance

Maintenance

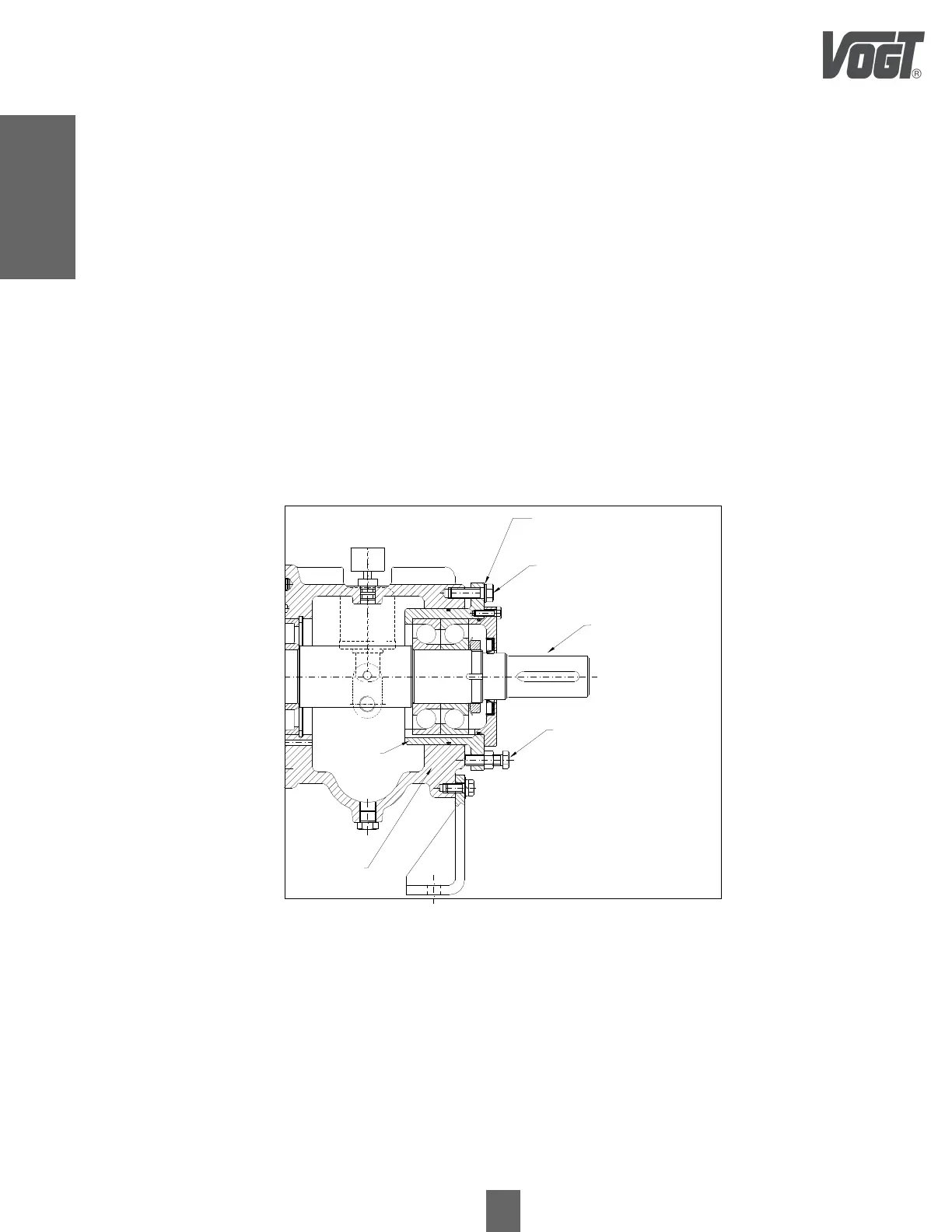

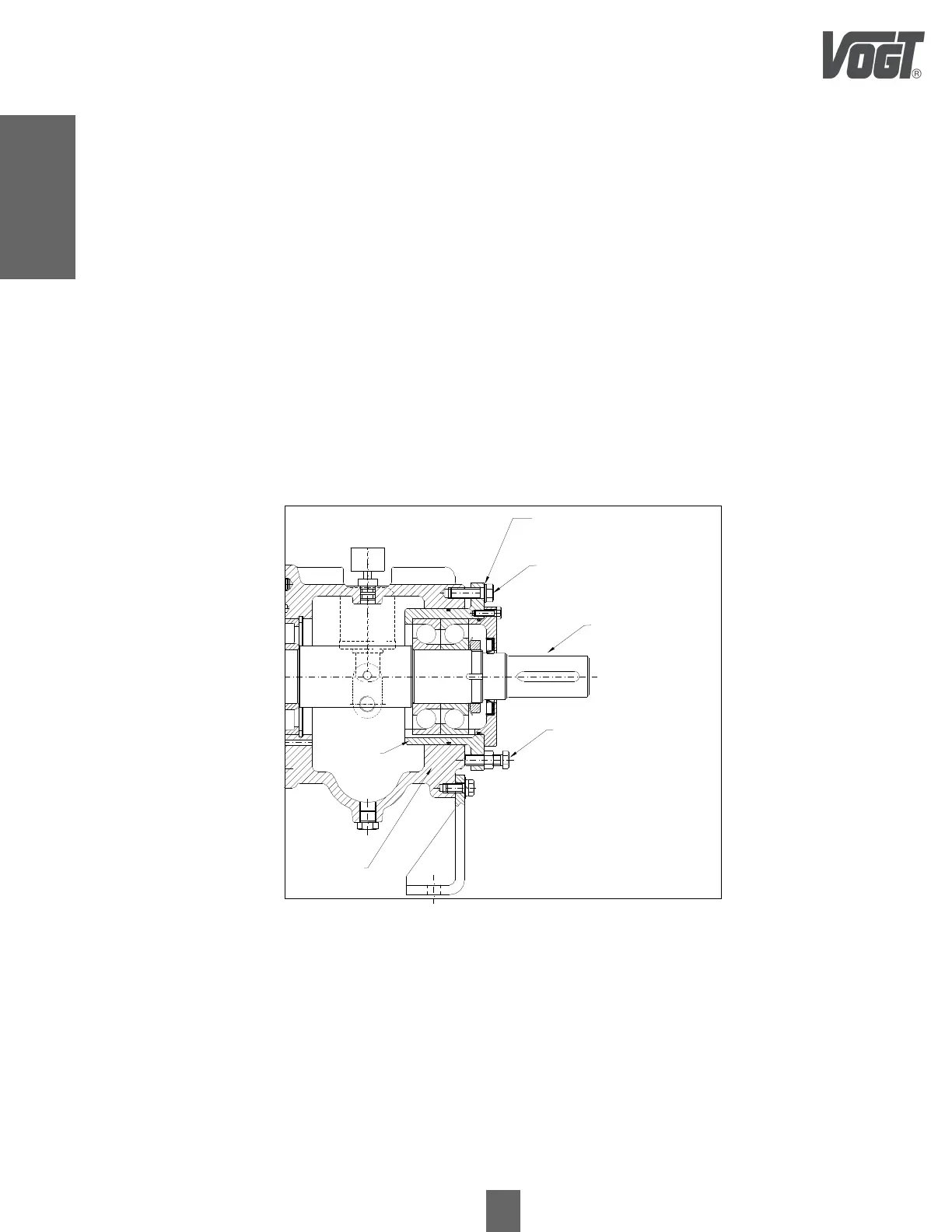

7.11.2 Impeller Clearance Adjustment Using Graduated Blades

• Remove the grid from the plug cover.

• Remove the flexible body from the coupling hub.

• Loosen the shaft adjusting bolts (fig.26) until a clearance of about 5 to 8 mm is achieved.

• Tighten the bearing housing - bearing housing bolts (fig.26), until the impeller stops in the pump housing. This is

checked by turning the shaft by hand until friction is felt.

• Loosen the bolts of the bearing housing. - Remove the bearing housing bolts (fig.26), until a clearance greater than

0.5mm is achieved.

• Place a calibrated sheet with a thickness of 0.4mm under the head of the bearing housing - bearing body bolt

(fig.26).

• Screw the bearing housing - bearing body bolts (fig.26), until it rubs against the calibrated sheet (0.4mm).

• Remove the calibrated sheet.

• Tighten the shaft adjustment bolts, until the bearing housing touches the bearing housing - bearing body bolts

(fig.26), until it rubs against the calibrated sheet (0.4mm). -Remove the bearing body (fig.26).

• Tighten the bearing housing - bearing body bolts (fig.26).

• Install the flexible coupling core body. Install the core cover grid.

Bearing housing

Case Bolts

Bearing Holder -

Bearing Body

Shaft Adjustment Bolts

Graduated Laminates

Axis

Bearing body

$% re-

Loading...

Loading...