19

5.1 GAS SUPPLY INSTALLATION

Inspect the entire installation including the gas meter, test for

tightness and purge. Refer to BS 6891 (I.S. 813 in ROI) for

specifi c instruction.

5.2 THE HEATING SYSTEM

The appliance contains components that may become damaged

or rendered inoperable by oils and/or debris that are residual

from the installation of the system, consequently it is essential

that the system be fl ushed in accordance with the following

instructions.

5.3 INITIAL FILLING OF THE SYSTEM

Ensure both fl ow and return service valves are open, remove

appliance casing as described in 4.7.1, identify the automatic air

release valves (AAV) and loosen the dust cap/s by turning the

cap anti-clockwise one full turn. Ensure all manual air release

valves located on the heating system are closed. Connect the

fi lling loop, slowly proceed to fi ll the system by fi rstly opening

the inlet valve connected to the fl ow pipe, and then turning the

lever on the fi ll valve, to the open position. As water enters the

system the pressure gauge will begin to rise. Once the gauge

has reached 1 BAR close both valves and begin venting all

manual air release valves, starting at the lowest fi rst. It may be

necessary to go back and top-up the pressure until the entire

system has been fi lled. Inspect the system for water tightness,

rectifying any leaks.

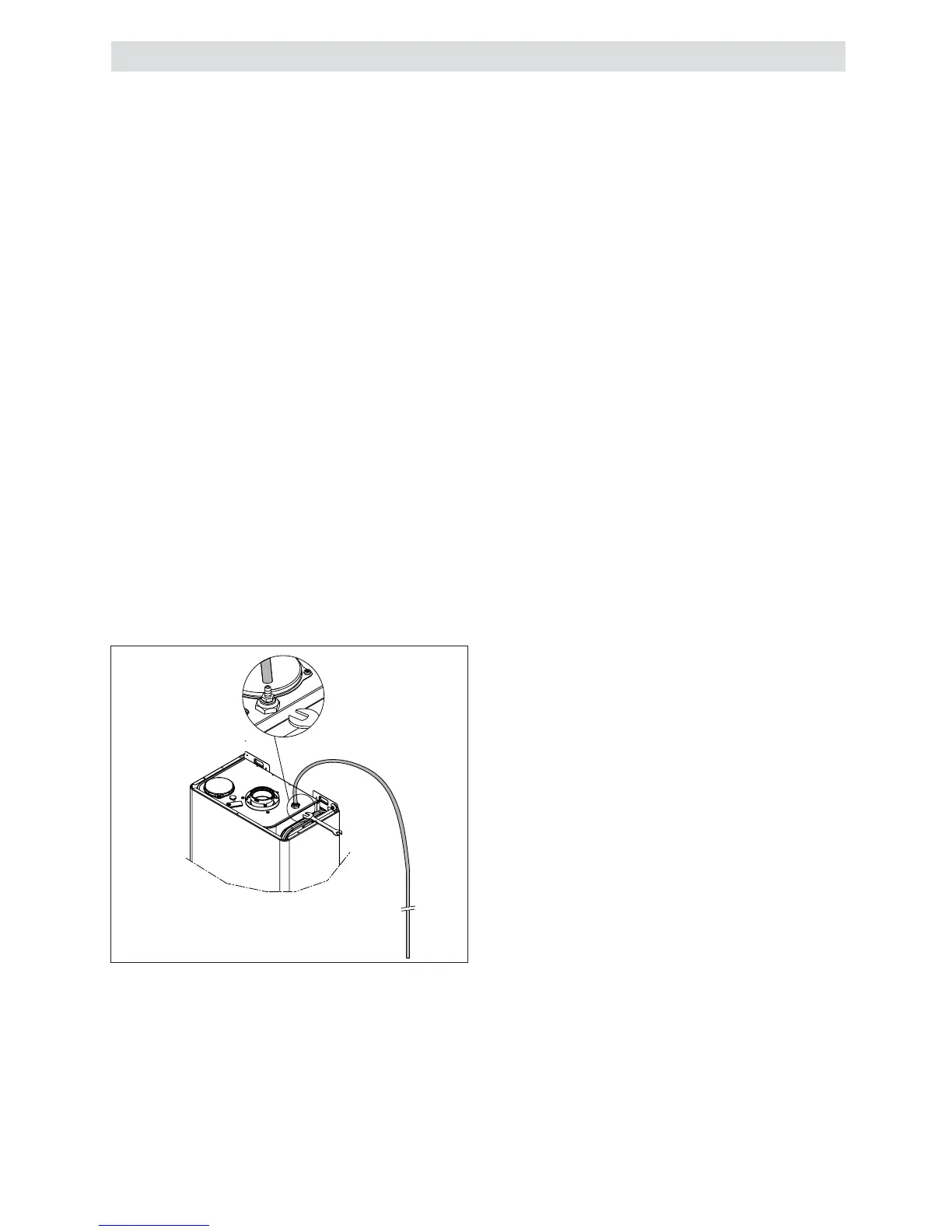

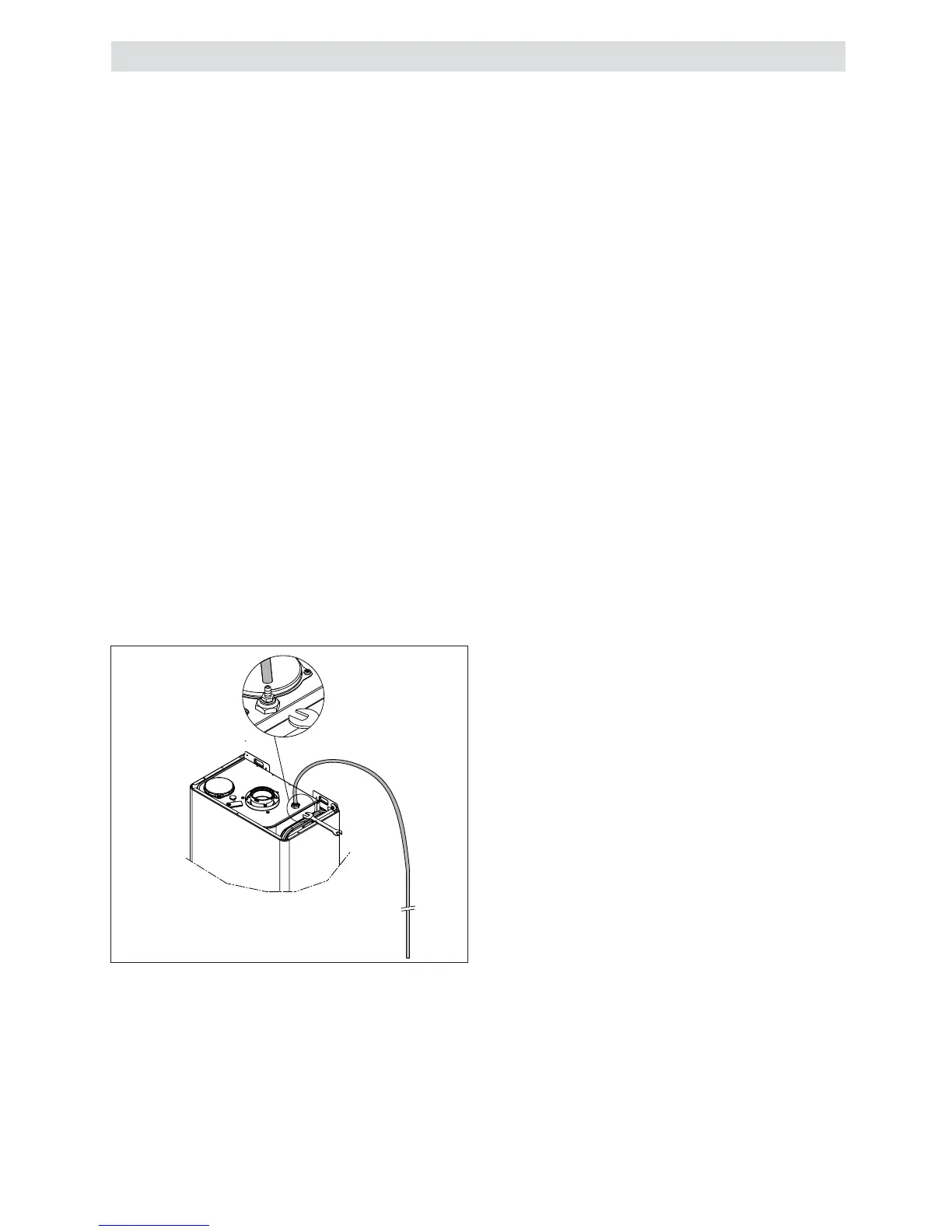

5.3.1 MANUAL AIR RELEASE (fi g. 27)

When the boiler has been fi lled for the fi rst time or the system

has been drained and refi lled, it will be necessary to release

any air that may have become trapped within the appliance heat

exchanger. Slacken the bleed screw until water is released

and then close.

IMPORTANT, THERE ARE NO OTHER MANUAL AIR RE-

LEASE VALVES LOCATED ON THE APPLIANCE.

5.4 INITIAL FLUSHING OF THE SYSTEM

The whole of the heating system must be fl ushed both cold

and hot as detailed in 5.8. Open all radiator or heating valves

and the appliance fl ow & return service valve. Drain the boiler

and system from the lowest points. Open the drain valve full

bore to remove any installation debris from the boiler prior to

lighting. Refi ll the boiler and heating system as described in 5.3.

5.5 PRE-OPERATION CHECKS

Before attempting the initial lighting of the appliance, the fol-

lowing checks must be carried out:

• ensure all gas service valves from the meter to the appliance

are open and the supply pipe has been properly purged;

• ensure the proper electrical checks have been carried out,

Fig. 27

(see 7.8) particularly continuity, polarity and resistance to

earth;

• ensure the 3 AMP fuse – supplied with the appliance – has

been fi tted;

• ensure the system has been fi lled, vented and the pressure

set to 1 BAR;

• ensure the fl ue system has been fi tted properly and in ac-

cordance with the instructions;

• ensure all appliance service valves are open.

5.6 INITIAL LIGHTING

Ensure the electrical supply to the appliance is switched on.

Ensure any external controls are switched to an ‘ON’ position

and are calling for heat. Move the selector switch to the ON

position, the appliance will now operate as described in 1.2.

Should the appliance fail to ignite, refer to 5.6 and/or section 7

(mode of operation, parameter setting & faultfi nding).

5.7 CHECKING GAS PRESSURE AND COMBUS-

TION ANALYSIS

The appliance is factory set so should require no additional

adjustment once installed. However to satisfy the requirements

of GSIUR 26/9 (I.S. 813 ROI), it will be necessary to gas rate

the appliance using the gas meter that serves the appliance

and carry out a combustion analysis check in accordance with

BS 7967 (UK) to ensure that correct combustion is occurring,

see fl ow chart on page 37.

Additionally, if the gas valve has been adjusted, replaced, or the

appliance has been converted for use with another gas type,

then it becomes necessary to carry out a combustion analysis

check to ensure that correct combustion is occurring.

If there are no means to carry out a combustion analysis check,

then it will not be possible to complete the commissioning

procedure.

Details on how to carry out the combustion analysis can be

found in section 7.

IMPORTANT

It’s imperative that a suffi cient dynamic – gas – pressure is

maintained at all times. Should the dynamic gas pressure fall

below an acceptable level, the appliance may malfunction or

sustain damage.

5.8 FINAL FLUSHING OF THE HEATING SYSTEM

The system shall be fl ushed in accordance with BS 7593 (I.S.

813 ROI). Should a cleanser be used, it must be suitable for

Aluminium heat exchangers. It shall be from a reputable manu-

facturer and shall be administered in strict accordance with the

manufacturers’ instructions and the DWTA code of practice.

NOTE

Chemicals used to cleanse the system and/or inhibit corrosion

must be pH neutral, i.e. they should ensure that the level of the

pH in the system water remains neutral. Premature failure of

certain components can occur if the level of pH in the system

water is out-with normal levels.

5.8.1 INHIBITORS

See Section 3 “General Requirements”.

5.9 SETTING THE FLOW OUTLET TEMPERA-

TURE

The fl ow outlet temperature can be adjusted between 40 °C -

80 °C for standard CH system by using the Heating thermostat

knob (see fi g.1).

5.9.1 SETTING THE DHW OUTLET TEMPERATURE

The DHW outlet temperature can be adjusted between 37 °C

- 60 °C via the DHW thermostat knob (see fi g.1).

5.10 SETTING THE SYSTEM DESIGN PRESSURE

The design pressure should be a minimum of 0.5 BAR and a

maximum of 1.5 BAR. The actual reading should ideally be 1

BAR plus the equivalent height in metres (0.1 BAR = 1 metre) to

the highest point in the system above the base of the appliance

(up to the maximum of 1.5 BAR total). N.B. The safety valve

SECTION 5 - COMMISSIONING

Loading...

Loading...