29

7.10.1 CHECKING THE FAN SPEED

Locate the CO button (see Fig 44 pos SW1).

Select the main selector switch to the ON position, press the

CO button once, the display will then scroll through the fan

speeds along with the relevant icon.

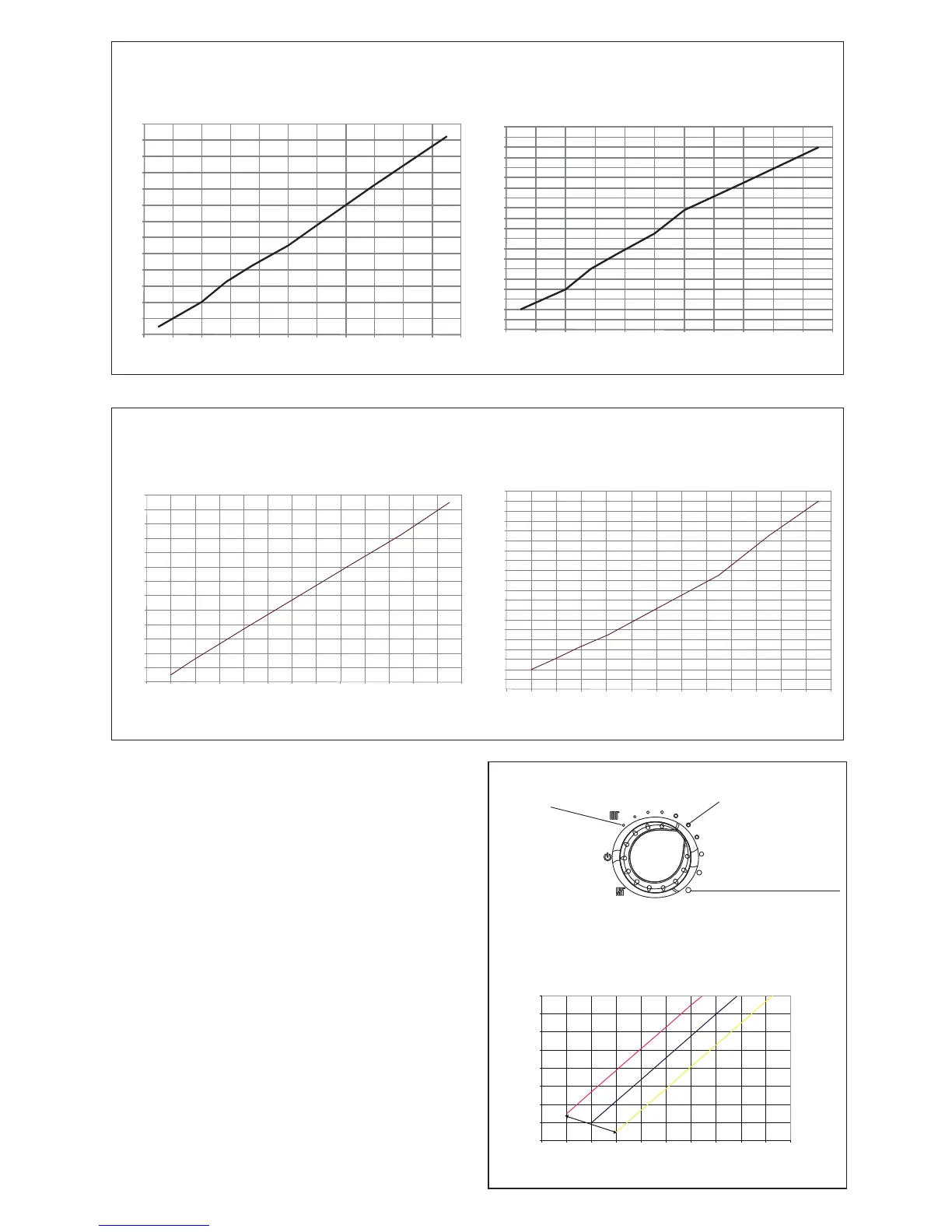

7.10.2 THERMOREGULATION

To set the temperature regulation curve, locate potentiometer

(P3). By turning (P3), the curve is shown on the LCD display.

The user can adjust the temperature of the heating system

indirectly by changing the required room temperature from

between 15°C & 25°C, this will allow the PCB to recalculate

the system temperature required, the default temperature for

calculating the curve is 20°C.

The graph below can be used to determine the correct curve

setting.

REFERENCE

TEMPERATURE 15 °C

REFERENCE

TEMPERATURE 20 °C

REFERENCE

TEMPERATURE 25 °C

20 °C

25 ° C

15 °C

10

20

30

40

50

60

70

80

90

-20-15-10-5051015202530

ROOM TEMPERATURE CURVE OFFSET

DELIVERY TEMPERATURE (°C)

EXTERNAL TEMPERATURE (°C)

Fig. 46

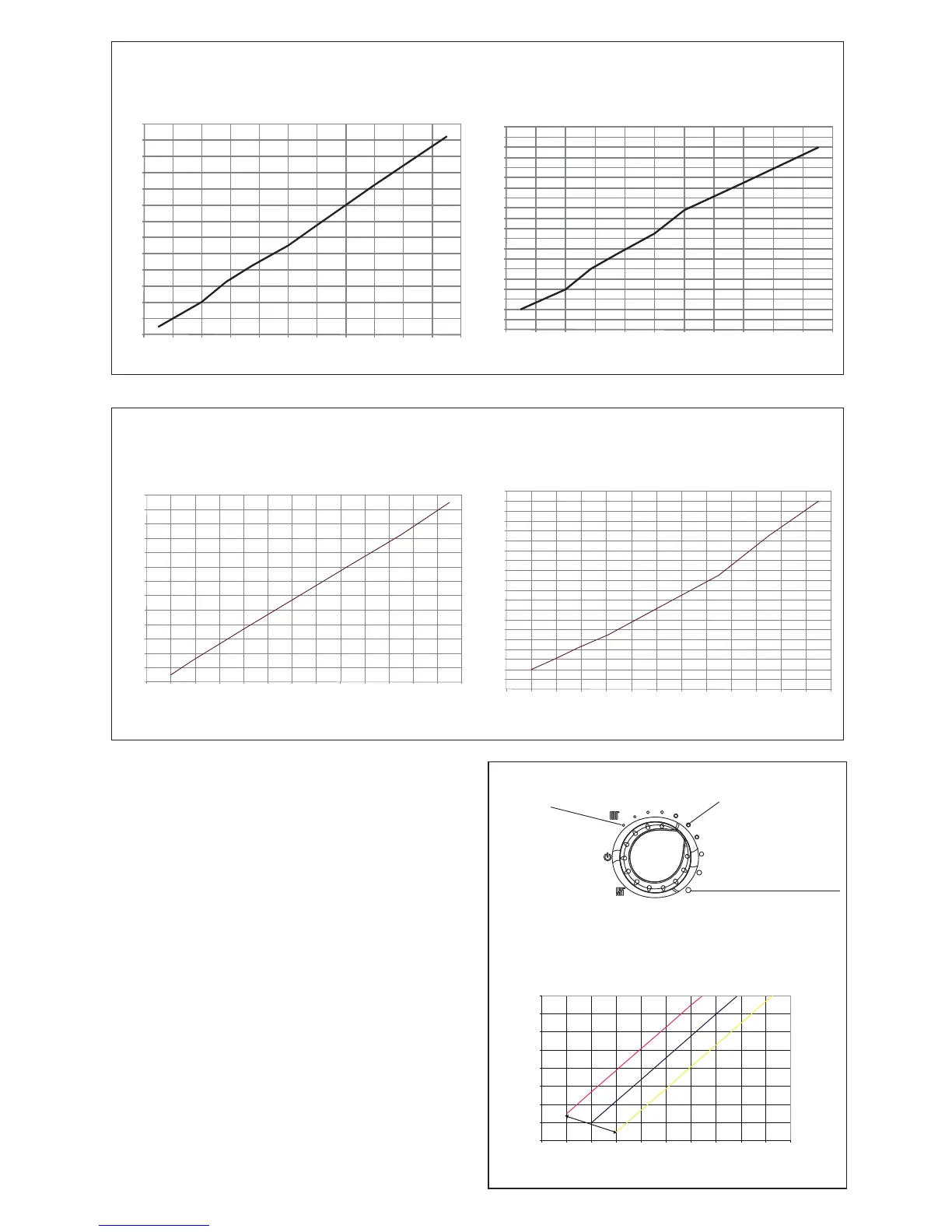

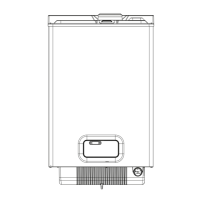

The boiler is supplied with the adjustments shown in the table. Depending on plant engineering requirements or regional fl ue gas emission limits it is, however,

possible to modify this value, referring to the graphs below.

COs.a. curve (Qnheating)

Heat output (kW)

HTG curve (Qnheating)

Heat output (kW)

Fan rotations (rpm)

CO emissions s.a. (p.p.m.)

Compact 29A

The boiler is supplied with the adjustments shown in the table. Depending on plant engineering requirements or regional fl ue gas emission limits it is, however,

possible to modify this value, referring to the graphs below.

Loading...

Loading...