Service and maintenance

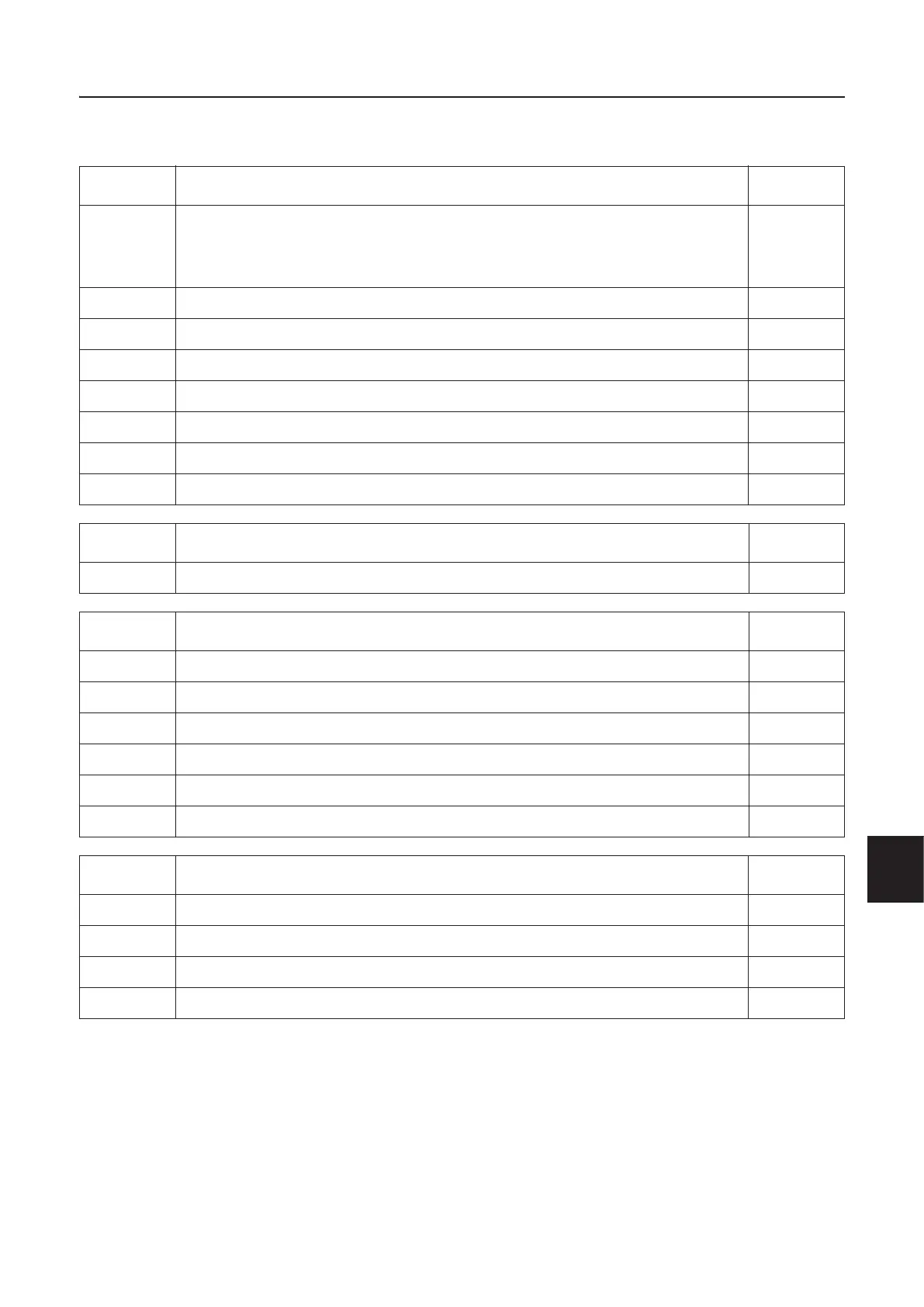

Lubrication and service chart 105

Position Measures every 10 operating hours Page

General inspection

(Oil, water and fuel leaks, machine components and hoses, fittings and hydraulic

connections, function of control elements, working lights, control lights and diesel

engine).

1 Lubrication chart (see lubrication and maintenance plan) 104

2 Checking the fuel level 88

3 Check the coolant level 90

4 Cleaning the dust valve 93

5 Checking the engine oil level 86

8 Checking the track tension 98

9 Checking the hydraulic oil level 99

Position Measures every 50 operating hours Page

2 Draining the fuel prefilter / water separator 88

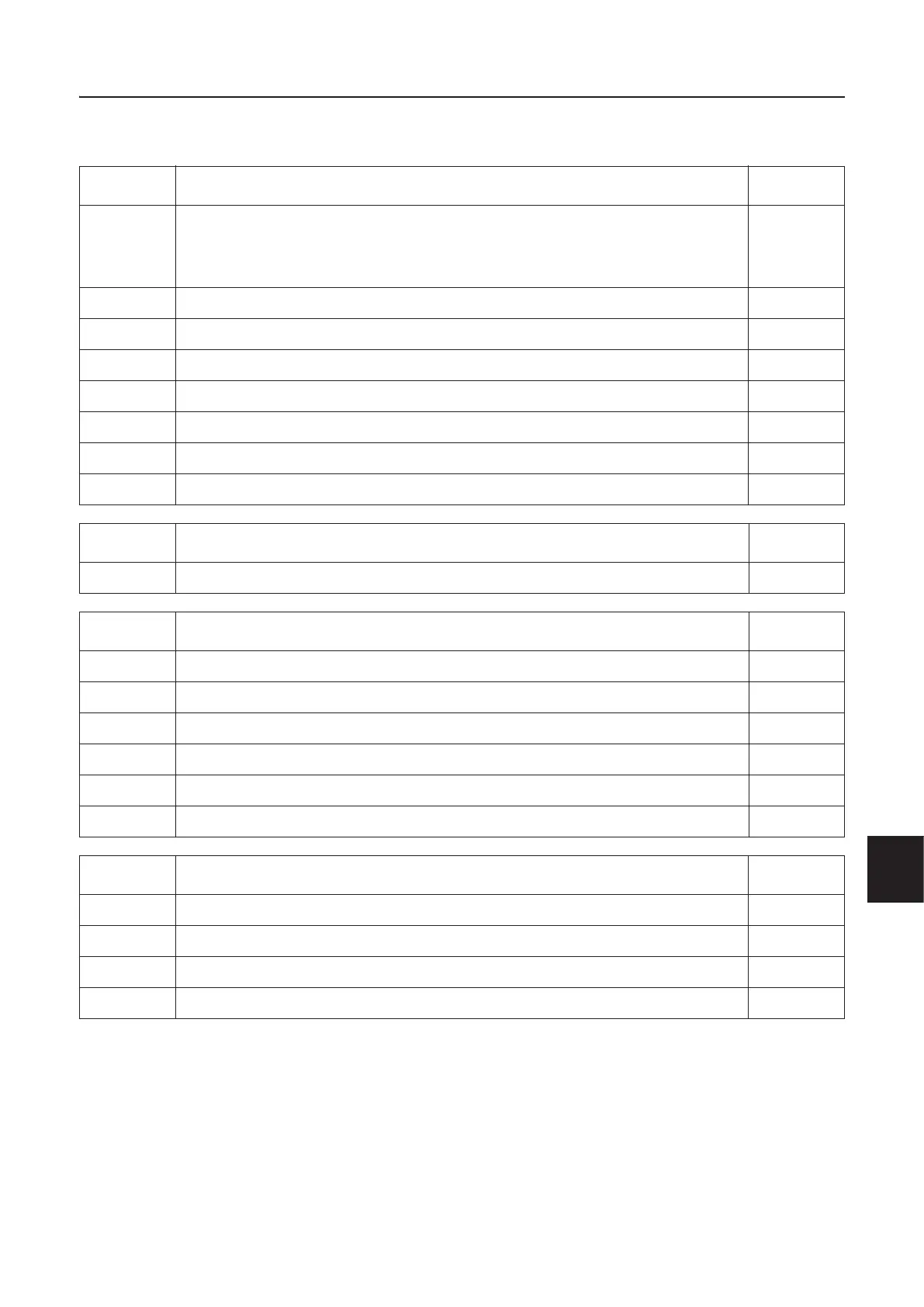

Position Measures after the first 100 operating hours Page

2 Draining the fuel prefilter / water separator 88

5 Changing the engine oil (1st service) 86

5 Changing the engine oil filter (1st service) 87

9 Changing the hydraulic oil filter (1st service) 101

Check the valve rocker arms for correct adjustment (1st service)*

Check tightening torques for engine fastening screws (1st service)*

Position Measures every 250 operating hours Page

5 Checking the fan belt tension 92

4 Cleaning the air filter cartridge 93

3 Cleaning the radiator cooling fins 102

7 Checking the oil level in the track reduction gear 97

Loading...

Loading...