Chapter 6 Fault diagnosis and solutions IR610 high performance vector control frequency inverter user manual

- 150 -

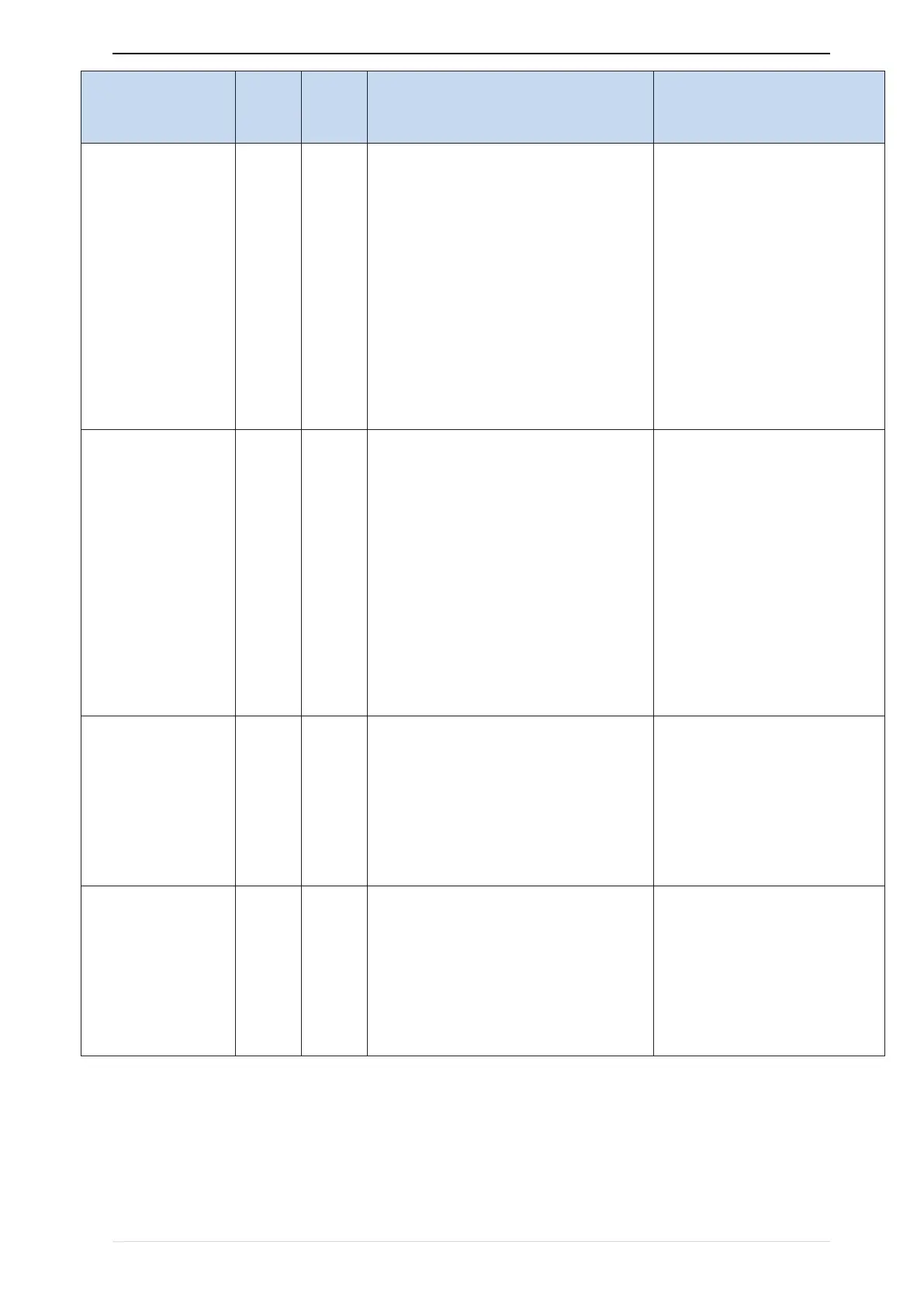

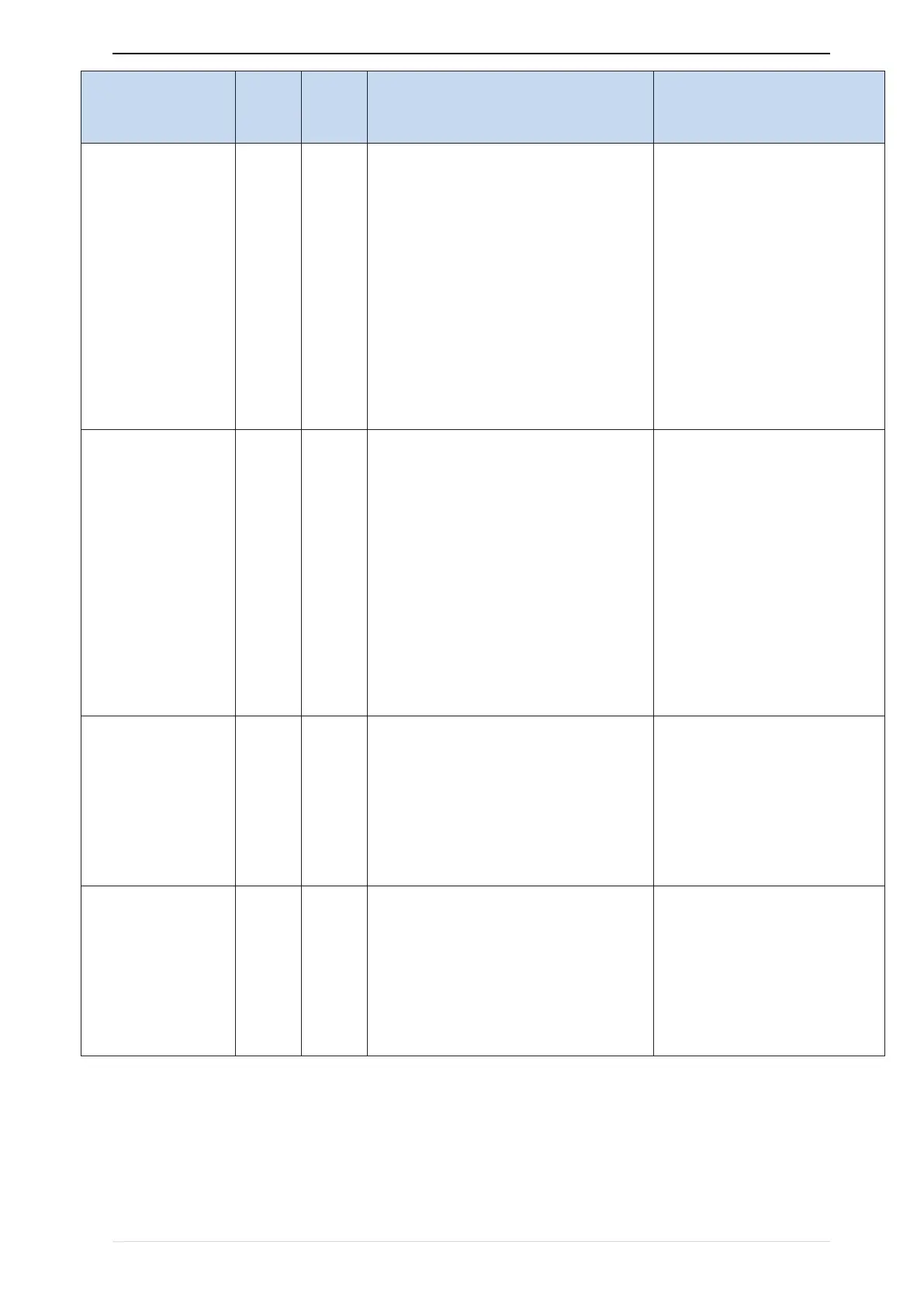

1: The cable connecting the frequency

inverter and the motor is faulty.

2: The frequency inverter's

three-phase outputs are unbalanced

when the motor is running.

3: The drive board is faulty.

4: The IGBT module is faulty.

1:Eliminate external faults.

2: Check whether the

Motor three phase winding

is normal.

3: Ask for technical support.

4: Ask for technical support.

1: The ambient temperature is too

high.

2: The air filter is blocked.

3: The fan is damaged.

4: The thermally sensitive resistor of

the IGBT module is damaged.

5: The inverter IGBT module is

damaged

1:Lower the ambient

temperature.

2: Clean theairfilter.

3: Replace thedamaged fan.

4: Replace the damaged

thermally

sensitive resistor.

5: Replace the inverter module.

1:the temperature sensor wiring is

loose

2:the motor temperature is too high

3:Themotor temperature sensor detects

that the temperature is greater than the

set threshold.

1:check the temperature sensor

wiring

2:Improve the carrier

frequency, strengthen the heat

dissipation of the motor, reduce

the load, and select a motor

with higher power.

3:Check if the set threshold is

reasonable.

By wave

current

limitingfault

1: The load is too heavy or locked-

rotor occurs on the motor.

2: The frequency inverter model is of

too small power class

1: Reduce the load and check

the motor and mechanical

condition.

2: Select a frequency inverter of

higher power class.

Loading...

Loading...