20

GB

SETTING THE SPRAY GUN /STARTING OPERATION/

Mordants, glazes, im-

pregnations, oils

undiluted FineSpray spray

attachment

(brown) recom-

mended

Clear varnishes, syn-

thetic enamels, col-

oured paints, alkyd

resin varnishes

observe manufac-

turer’s instructions

Primers, radiator

paints, hammer ef-

fect enamels

observe manufac-

turer’s instructions

Anti-rust paints, spe-

cial-eect paints

observe manufac-

turer’s instructions

Multicolor paints,

textured paints

observe manufac-

turer’s instructions

WallSpray spray

attachment

(white) recom-

mended

7 SETTING THE SPRAY GUN

7.1 SETTING THE REQUIRED SPRAY PATTERN

Attention:

Never pull trigger while adjusting the air

cap settings.

The alignment of the spray jet can be determined by turning

the black adjusting ring (Fig. 3, 1).

A horizontal at jet

for vertical surfaces

B vertical at jet

for horizontal surfaces

It is also possible to switch between a wide ( ) and a compact

( ) spray jet with the adjusting lever (Fig. 4, 1).

7.2 SETTING THE AMOUNT OF MATERIAL FIG. 5)

The material volume can be adjusted incrementally from 1

(minimum) to 12 (maximum) by turning the material volume

control (Fig. 5, 1).

7.3 SETTING THE AMOUNT OF AIR FIG. 6

Turn the air volume control (Fig, 6, 1) clockwise to increase the

air volume or anti-clockwise to reduce the air volume (note

arrow on body of gun).

Setting the air and paint ow rate correctly is im-

portant for atomisation, overspray and working

speed.

7.4 ALIGN THE FEED TUBE

If the feed tube is positioned correctly, the container

contents can be sprayed without almost any residue.

When working on lying objects:

Turn the feed tube forwards. (Fig. 7 A)

Spraying work when working on overhead objects:

Turn the feed tube rearwards. (Fig. 7 B)

8 STARTING OPERATION

Before connecting to the

mains supply make sure that

the mains voltage corre-

sponds to the operating volt-

age on the rating plate. The

unit must be connected with

a properly earthed shock-

proof socket.

1. Unscrew the container from the spray attachment.

2. Pour in the prepared coating material.

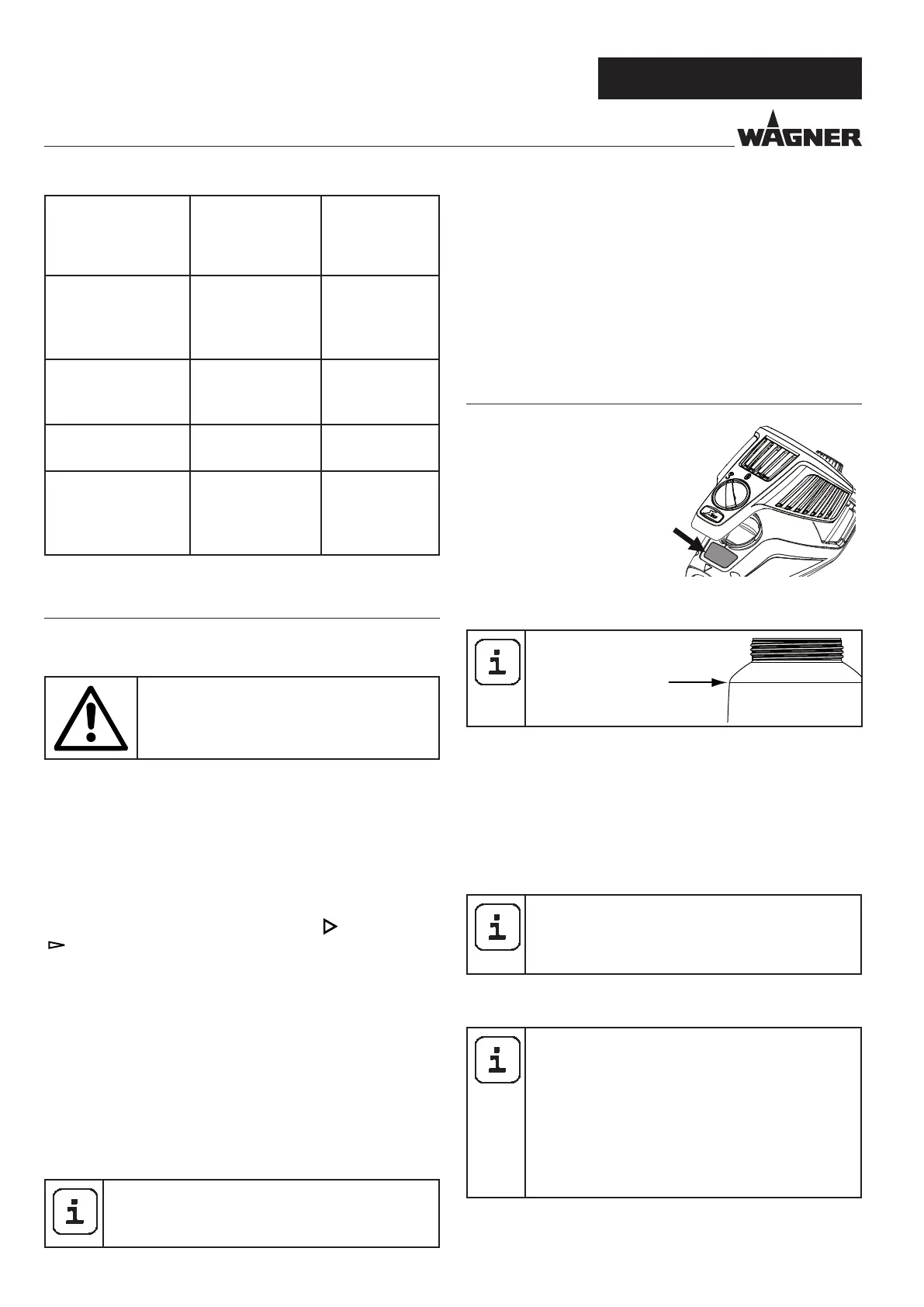

Fill the container

with maximum

1000 ml.

1000ml

3.

Fit the appropriate lter to the feed tube depending on the

coating material used (Fig. 9, 1)

Low-viscosity coating materials

Fine lter (red)

Viscous coating materials

Coarse lter (white)

4.

Align the feed tube. (Fig. 7)

5. Screw the container rmly onto the spray attachment.

6. Connect spray attachment and FC 3500. (Fig. 2)

When working with the FC 3500 we recommend

using the supplied carrying strap. This enables the

weight of the FC 3500 to be better distributed and

the work can be carried out with less eort.

7.

Both carabiner locks on the carrying strap have to be

secured to the xture. (Fig. 8)

The xture for the carrying strap can be mounted

to the other side of the FC 3500 if this is preferred.

Do this by unscrewing the two large screws (g. 8,

1). Mount the xture to the other side by inserting

the screws into the relevant holes. Please make

sure that you use only the screws that have

been provided. Screws of the wrong length or

diameter can damage the device. Never tighten

the screws without the xture.

8.

Plug in the power cable.

9. The device is now ready for operation.

Loading...

Loading...