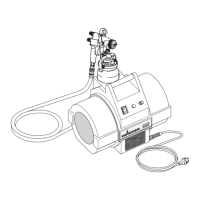

Why is the delivery rate too low on my WAGNER Paint Sprayer?

- HHannah RussellAug 14, 2025

If your WAGNER Paint Sprayer's delivery rate is too low, it could be due to damaged inlet or outlet valves; inspect and replace them if necessary. Another cause could be that the unit is sucking in air; check the suction system, inlet valve pusher, and gaskets inside the inlet valve. Also, ensure the suction filter isn't clogged and that the material's viscosity isn't too high. If needed, check the valve lift for inlet valve 341247 (2.4 mm).