Do you have a question about the WAGNER Super Finish 23 PLUS and is the answer not in the manual?

Specifies minimum flash point for coating materials to prevent flammability.

Details requirements for avoiding explosive atmospheres during operation.

Warns against ignition sources like open fires and sparks during spraying.

Highlights risks of injection injury from high-pressure spray jets.

Instructions for securing the spray gun to prevent accidental discharge.

Explains recoil force and potential for injury if unprepared.

Emphasizes the need for breathing apparatus when using solvents.

Recommends protective clothing, gloves, and skin cream.

Specifies the minimum required operating pressure for components.

Details safe handling, inspection, and replacement of high-pressure hoses.

Warns about static discharge causing sparks or flames and grounding requirements.

Covers ventilation needs for rooms and requirements for suction systems.

Specifies load limits and usage for the unit's socket.

Covers ventilation needs for rooms and requirements for suction systems.

Specifies that the object to be coated must be earthed.

Warns about explosive gas/air mixtures and grounding when using solvents.

Warns against using high-pressure or steam cleaners on the unit.

Emphasizes that electrical work must be done by a skilled electrician.

Advises against using the unit on inclined surfaces to prevent wandering.

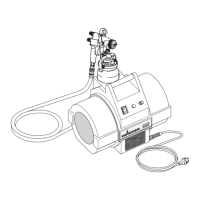

Describes the unit's use for airless atomization in workshops and on-site.

Discusses types of coating materials, viscosity, and filtering.

Warns about wear and tear from materials with sharp-edged additives.

Explains the importance of filters for fault-free operation and lists types.

Details the airless spraying process and its advantages.

Describes the electric motor, hydraulic pump, and diaphragm operation.

Lists components and symbols shown in the unit's diagram.

Provides instructions for transporting the unit and securing it in a vehicle.

Steps for altering the carriage to switch between suction and hopper systems.

Presents detailed technical specifications of the unit.

Steps for connecting and starting the unit with a suction system.

Steps for connecting and starting the unit with a 5-litre hopper.

Instructions for connecting the hose and spray gun to the unit.

Details requirements for connecting the unit to the mains supply.

Information on connecting additional equipment to the unit's socket.

Procedure for flushing the unit with cleaning agent before first use.

Steps to ventilate the hydraulic system if the inlet valve sound is not audible.

Steps for introducing coating material and preparing the unit for spraying.

Instructions for cleaning the exterior of the unit.

Guidance on cleaning or replacing suction filters for optimal performance.

Steps for disassembling, cleaning, and reassembling the high-pressure filter.

Procedures for rinsing and cleaning the spray gun and its components.

Advice on annual checks and user servicing intervals for safety.

Checks for wear, damage, and conductivity of the high-pressure hose.

Steps for removing, replacing, and installing the inlet valve pusher.

Detailed procedure for removing and replacing the inlet valve.

Steps for disassembling, cleaning, and replacing the outlet valve.

Notes that pressure control valve replacement must be done by service.

Instructions for replacing the unit's power cable, requiring a qualified electrician.

Lists common wear parts like inlet and outlet valves and their symptoms.

Electrical wiring diagrams for the unit with and without a socket.

Lists various accessories available for the Super Finish 23 PLUS.

A table detailing tip markings, spray angles, bore sizes, and applications.

Describes the innovative 2SpeedTip nozzle with two nozzle cores.

A comprehensive list of spare parts for the Super Finish 23 PLUS unit.

Lists components and order numbers for high-pressure filters.

Lists components and order numbers for the trolley assembly.

Lists components and order numbers for the unit's frame.

Lists components and order numbers for the rigid suction system.

Lists components and order numbers for the 5-litre hopper.

Lists components and order numbers for the hopper with TopClean system.

Outlines the terms, duration, and registration for the product guarantee.

Details procedures for making claims and conditions that void the guarantee.

Provides contact information for Wagner service centers across Europe.

| Type | Airless paint sprayer |

|---|---|

| Max Pressure | 250 bar |

| Hose Length | 7.5 m |

| Voltage | 230 V |

| Frequency | 50 Hz |

| Nozzle Size | 0.015 - 0.023 inches |

Loading...

Loading...