51

B23 Maintenance Instructions

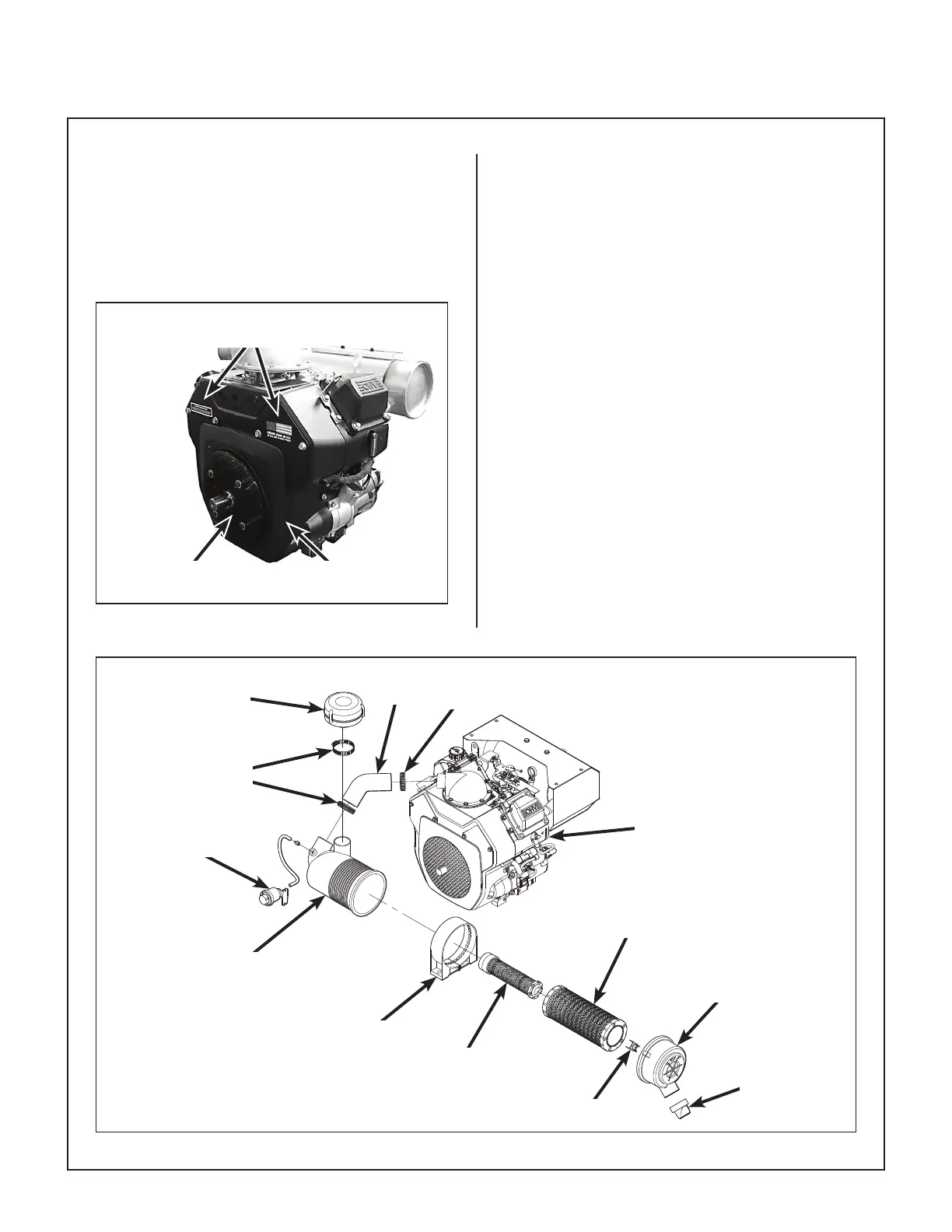

Cleaning

IMPORTANT: Yearly, it is good maintenance prac-

tice to remove the engine cooling shroud and clean

the cylinder head cooling ns and cooling fan

thoroughly to prevent overheating and extend

engine life. Make sure cooling shroud is reinstalled

properly. This procedure will require removing the

engine from the chassis.

Engine Cooling

Fin Access Panels

Rotating Engine Cooling

Air Intake Screen

Kohler Engine

Shroud

Engine Cooling Air Intake Screen

and Cooling Fin Access Panels

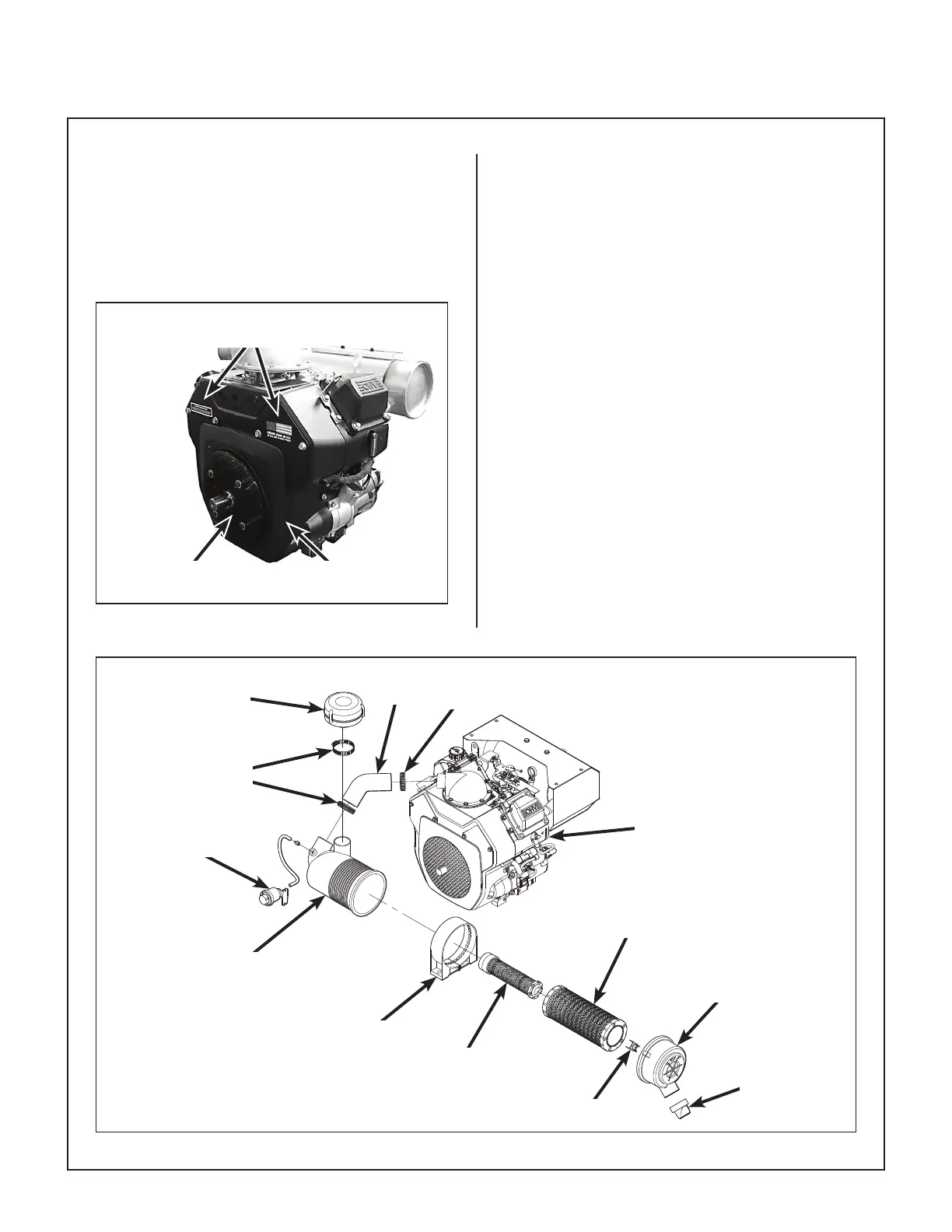

Engine Air Cleaner System

Donaldson Radialseal™ Air Cleaner

A remote mounted Donaldson Radialseal™ air

cleaner provides the air ltering function. The

paper lter element slides over an outlet tube

inside the air cleaner canister with radial sealing

action, reducing the possibility of dust leaks due to

improper lter installation. Intake design, internal

baing, and a dust ejection valve provide dust

separation and automatic precleaning action. Dai-

ly or frequent servicing of the air cleaner is not

required. Use the air lter restriction gauge on the

air cleaner outlet to indicate when the air lter

needs servicing–a yellow indicator will show when

the lter is overly restricting airow into the engine.

IMPORTANT: Use only Donaldson air lter ele-

ments for replacement (Donaldson P821575 or

Walker 5090-8 Primary/Donaldson P822858 or

Walker 5090-7 Safety Filter). Aftermarket lters

may not seal properly or lter eciently.

Engine Air Cleaner System Components

Primary Filter

Element

Cover Latch

Safety

Filter

Mounting

Band

Air Filter

Restriction Gauge

Donaldson

Air Cleaner

Donaldson

Air Cleaner Cover

Engine

Dust Ejection

Valve

Hose

Clamp

Turbine

Precleaner

Air Intake

Hose

Hose

Clamps

Loading...

Loading...