B23 Maintenance Instructions

Replacing and Repairing

63

Fuel Filter

DANGER

Gasoline is extremely ammable and can

be highly explosive. To minimize danger:

● Before servicing the fuel system:

1. Disconnect the spark plug leads.

2. Disconnect the negative (-) battery

cable from battery.

● Use only an approved fuel container for

gasoline.

● DO NOT allow open ames or sparks

near the machine while performing

maintenance or refueling; DO NOT

smoke while working with fuel.

● Wipe up spilled gasoline immediately

and completely.

Model B23 is equipped with an inline fuel lter

between the fuel tank and the fuel pump (low pres-

sure fuel pump). Visually inspect the lter periodi-

cally, and replace the lter every 400 hours. Use

Walker P/N 5020-3 or Kohler P/N 24-050-13, 9-12

microns for replacement lter.

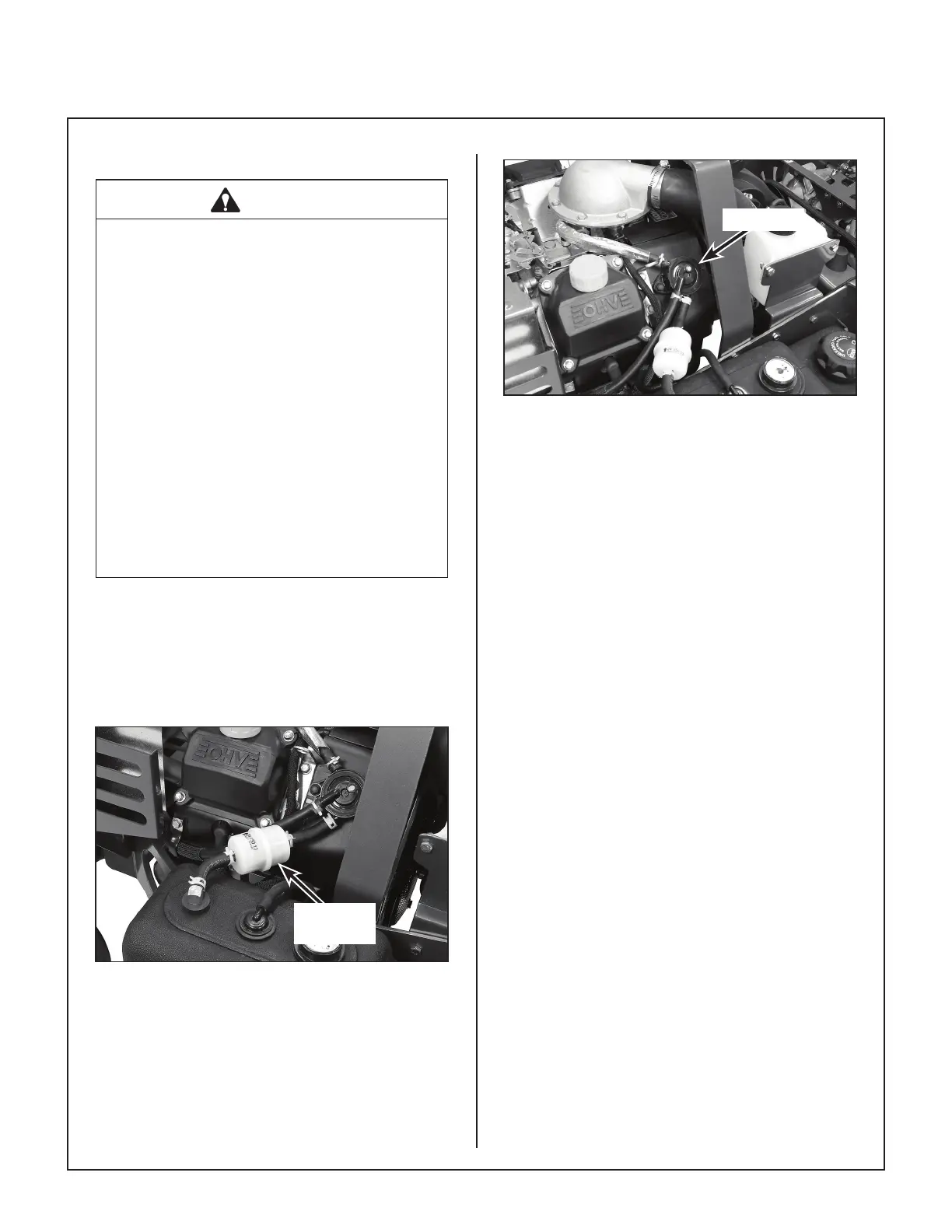

In-Line

Fuel Filter

Fuel Filter Location

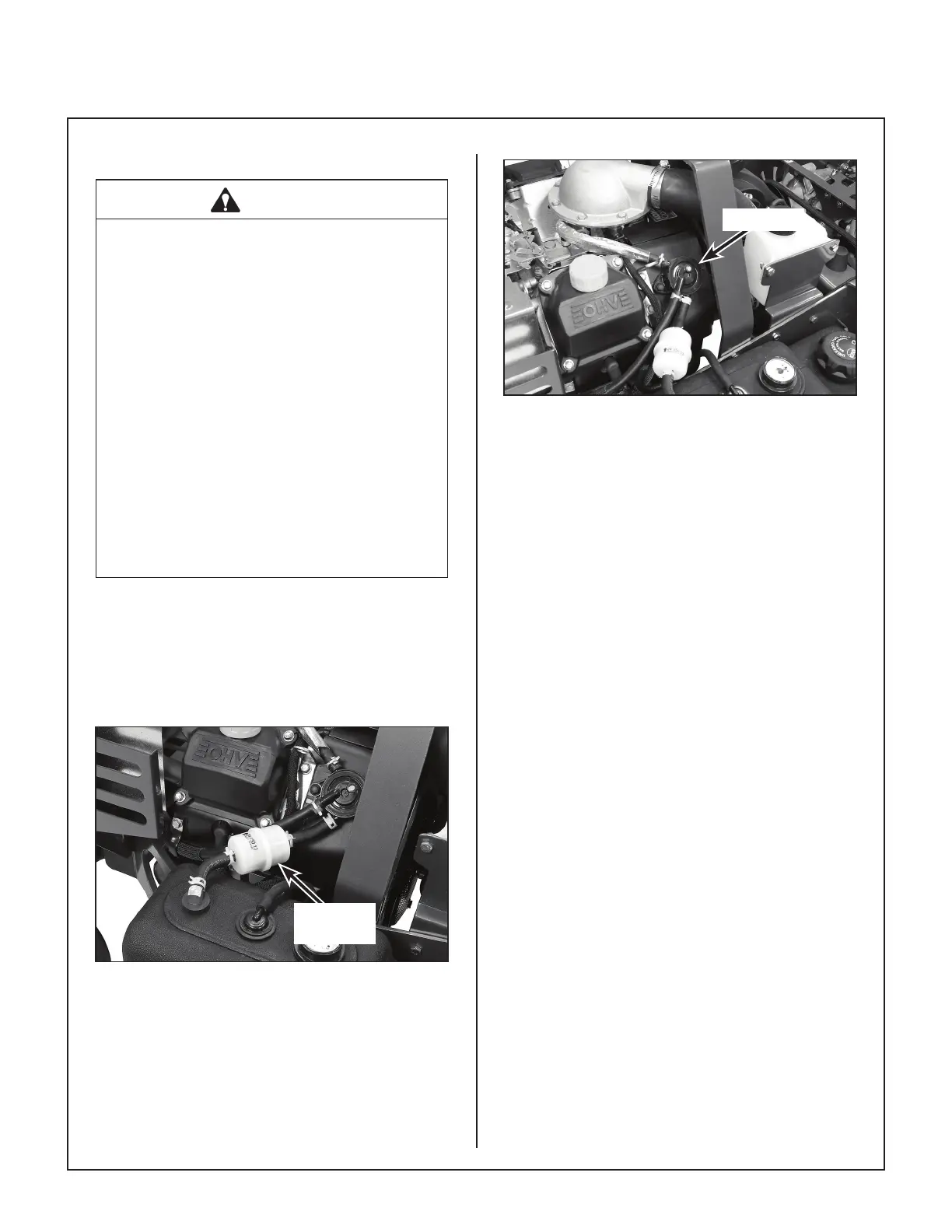

Fuel Pump

Fuel Pump Location

IMPORTANT: Replace the fuel lter only in a clean

area where the fuel line and connections will not

be contaminated by dust and dirt.

1. Expand and slide clamps on either side of the

lter away from lter and pull fuel lines o lter.

2. Replace lter, making sure that the arrow on

the lter is aligned with the fuel ow through

the lter.

3. Verify that the fuel lines and clamps are se-

curely attached, and that no fuel leaks are

present.

Blade Overload Shear Bolts

NOTE: Blade shear bolts are not used on belt-

driven decks.

On gear-driven decks, each cutting blade is keyed

to the blade hub by two (2) shear bolts (10-24 x

5/8 in. stainless steel machine screws). These

bolts are designed to shear and protect the blade

drive gearbox from damage if the blade encounters

a shock load.

Loading...

Loading...