Maintenance Instructions B23

Replacing and Repairing

64

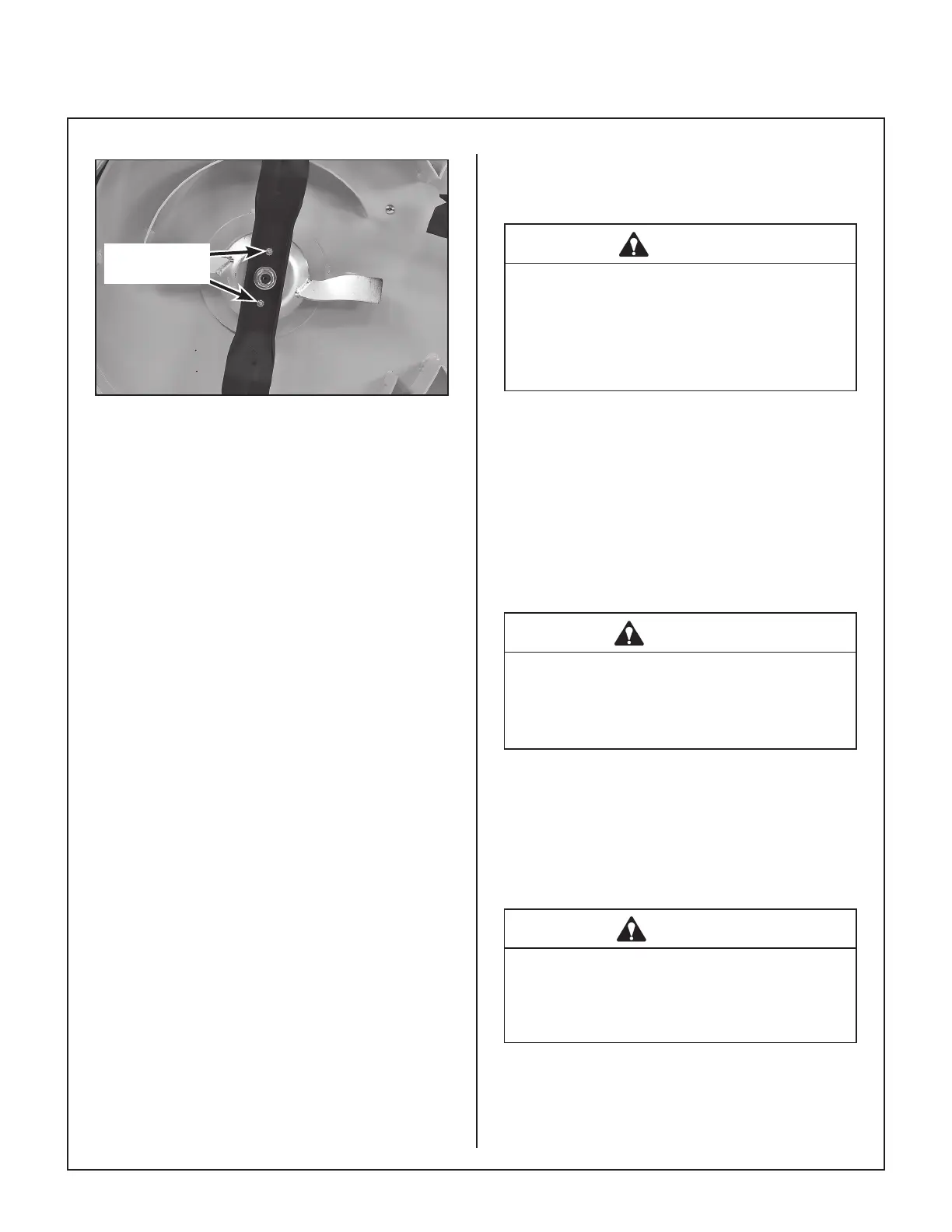

Cutting Blade

Shear Bolts

Cutting Blade Shear Bolts

NOTE: Tightening the 5/8-18 blade mounting nut

to 60 lb·ft (81 N·m) is also important for proper

shock load protection. It is important to not over-

tighten the mounting nut since this defeats (over-

rides) the function of the shear bolts.

If these bolts shear, remove the blade and install

new bolts. Refer to Sharpen Mower Blades on

page 56 which describes the blade removal and

installation procedure.

After reinstalling the blade, check blade timing (on

gear-driven decks) by moving blades through one

(1) complete revolution. Make sure blade tips

pass clear of each other. If timing is incorrect,

contact your Walker dealer.

Mower Blades

Mower blades are removed and remounted as

described in Sharpen Mower Blades on page

56. During the course of sharpening and

inspecting mower blades, if there are any of the

following conditions of wear or damage, blades

should be replaced for reasons of safety and

performance of the machine:

● An excessive amount of the at section of the

blade has been ground away (removed) when

the blade is sharpened. Replace the blade

when less than a 3/4 in. (19 mm) at section

remains at the blade tip.

● Examine ends of the blade carefully, especially

the intersection where the at section of the

blade turns up to form the “wing tip” (refer to

the illustration Mower Blade Prole for

Sharpening on page 57 for location of the

wing tip and wear area). Since sand and abra-

sive material can wear metal away in this area,

the blade should be replaced when metal

thickness has worn to 1/16 in. (1.6 mm) or

less.

DANGER

When blades are operated over sandy soil,

and if blades are allowed to wear, a “slot”

may be worn into the wing tip of blade.

Eventually a piece of the blade may break

o creating a serious potential for injury or

damage.

● Check the blades for straightness by marking

blade tip position inside the deck housing and

then rotating the opposite end of the blade to

the same position and comparing. If the dier-

ence in blade tip track is more than 1/8 in. (3

mm), the blade is bent and should be

replaced.

● Inspect the blade surface, especially in formed

areas, for cracks. Replace the blade if any

cracks are found.

WARNING

DO NOT try to straighten a blade that is

bent. NEVER weld a broken or cracked

blade. ALWAYS replace with a new blade to

assure safety.

Reinstall the blades following procedure from

Sharpen Mower Blades on page 56. If blades

are replaced, always use Walker original equip-

ment blades to ensure safety and optimum perfor-

mance. The quality and performance of replace-

ment blades oered by other manufacturers

cannot be guaranteed, they could be dangerous.

CAUTION

ALWAYS use genuine factory replacement

parts. Substitute parts CAN result in prod-

uct malfunction and possible injury to the

operator.

Loading...

Loading...