Maintenance Instructions LUBRICATION

42

Mower Deck Gearbox Lubrication

On gear driven decks, the mower deck gearboxes

(tee gearbox and blade drive gearboxes) are con-

nected as a unitized assembly, and oil ows freely

between them. The gearboxes are permanently lu-

bricated (oil lled) and sealed requiring no sched-

uled lubrication. However, the gearbox oil seals

should be checked every 25 hours for indication of

an oil leak; particularly the lower seals on the

blade drive gearboxes should be inspected, since

they operate in a dirty environment. If an oil leak is

noted, replace the oil seal and relubricate the gear-

box assembly as follows:

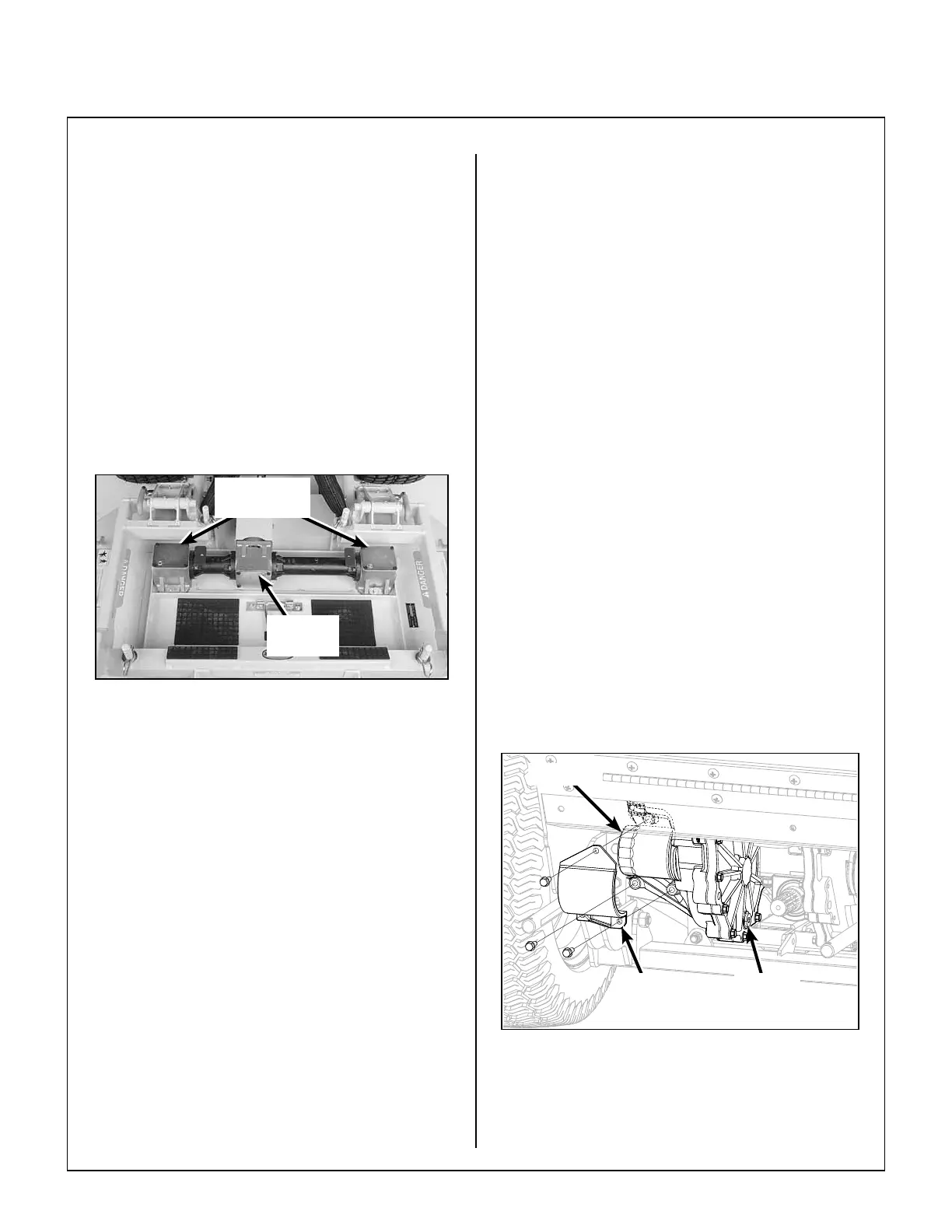

1. Remove gearbox cover (footrest). Deck orien-

tation should be the normal operating position.

Blade Drive

Gearboxes

Tee

Gearbox

Mower Deck Gearboxes

(Shown with Gearbox Cover

Removed for Clarity)

2. Clean the area around the individual gearbox

cover plates to prevent contaminants from en-

tering the gearcase.

3. Remove the screws securing the cover plates

on the blade drive gearboxes.

4. Check the level of lubricant in the gearboxes. If

the lubricant is low, add SAE E.P. (Extreme

Pressure) 80W-90 (API GL-5) gear lube until

the oil level is up to (submerges) the horizontal

shaft in the gearbox (shaft parallel to cover

plate).

NOTE: In case the gearboxes are completely

drained of oil, approximately 5 . oz. (15 cl) of oil

per gearbox is required to rell the gear drive

assembly.

NOTE: Since the gearboxes are connected as

a unit by connector tubes, it is necessary to add

oil slowly. Allow a few minutes after adding oil

for the oil to ow throughout the assembly and

the oil level to stabilize before reassembly.

IMPORTANT: DO NOT overll the deck gear-

boxes. The gearbox assembly is not vented,

and overlling with oil will cause excessive pres-

sure and result in oil leaks.

5. Check condition of the cover gasket and replace

if worn or damaged. Reinstall gearbox cover

plates; torque screws to 24 lb·in. (2.7 N

·m).

Transaxle Oil and Filter Change

Change the transaxle oil after the initial break-in

period of 75-100 hours. Thereafter, change oil ev-

ery 400 hours of operation as follows:

1. Thoroughly clean the exterior of the transmis-

sion housing before servicing. Remove expan-

sion tank cap to allow venting. Using a 1/4 in.

hex wrench, remove the plug on the lower in-

side of each transaxle allowing the oil to drain.

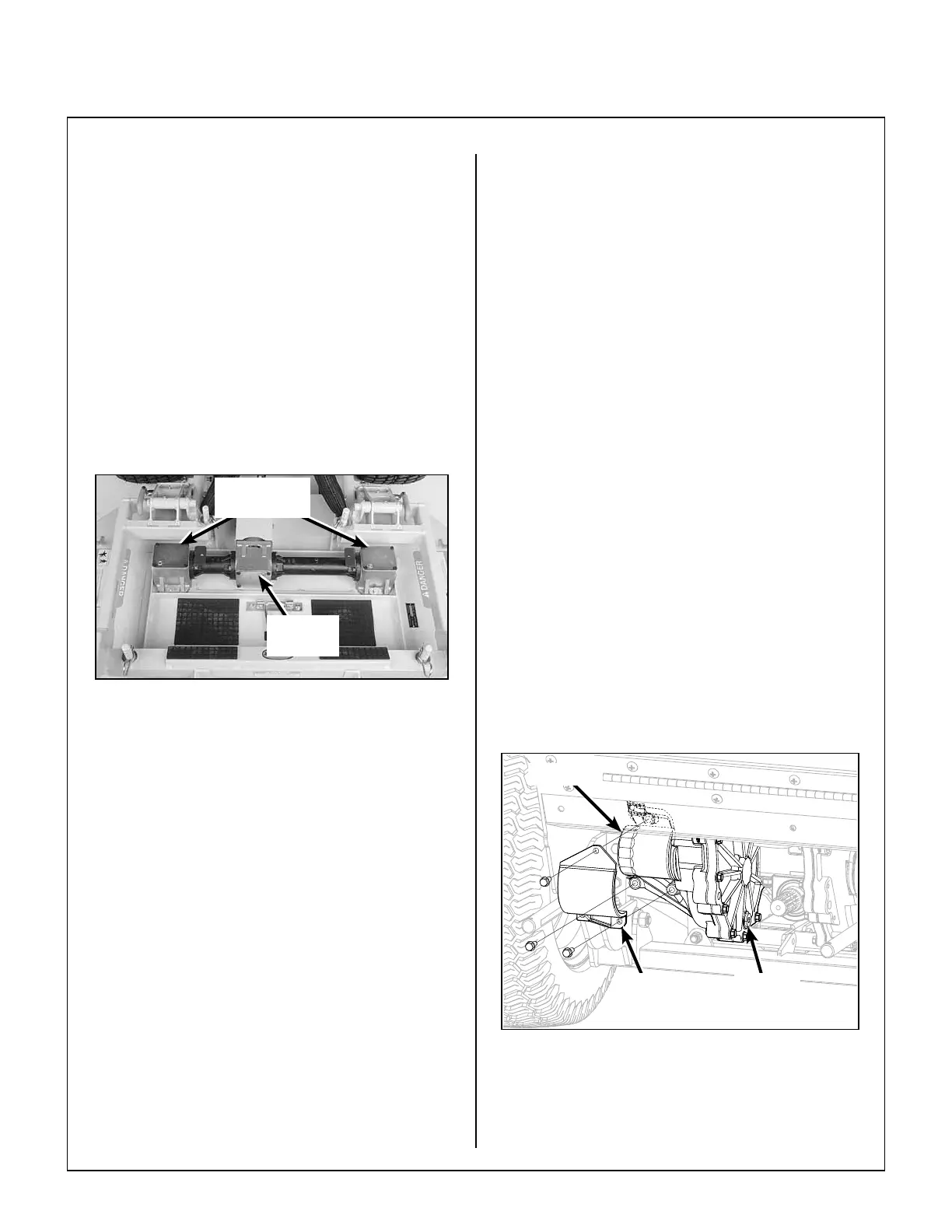

2. Remove the oil lter guard, remove and replace

the oil lter using an oil lter wrench. Tighten

lter by turning lter 3/4 to 1 turn after gasket

contacts the lter base surface. Reinstall the oil

lter guard. (Refer to Transaxle Oil Drain

Plug, Filter, and Guard Location illustration.)

Oil Filter

Guard

Oil Drain

Plug

Oil Filter

Transaxle Oil Drain Plug, Filter, and

Guard Location

(Shown with Deck Support Arms

Removed for Clarity)

Loading...

Loading...