49

Maintenance Instructions CLEANING

IMPORTANT: Use only Cummins/Fleetguard air

lter elements for replacement (Walker 2090-1 and

2090-3). Aftermarket lters may not seal properly or

lter efciently.

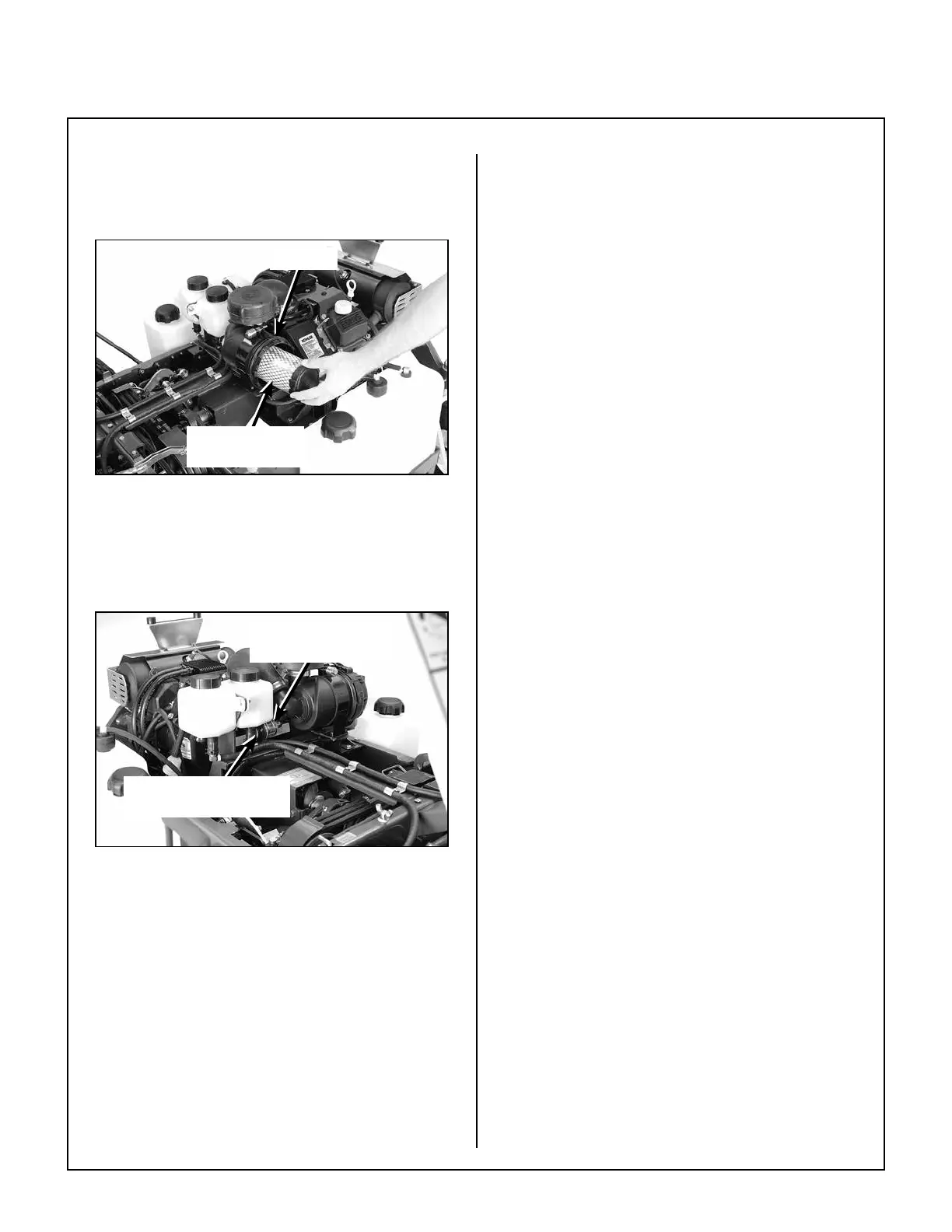

Canister

Primary

Filter Element

Air Cleaner Components

(Shown with Cover Removed)

IMPORTANT: The Cummins/Fleetguard air cleaner

uses a dry paper-type air lter element. NEVER ap-

ply oil to the paper element.

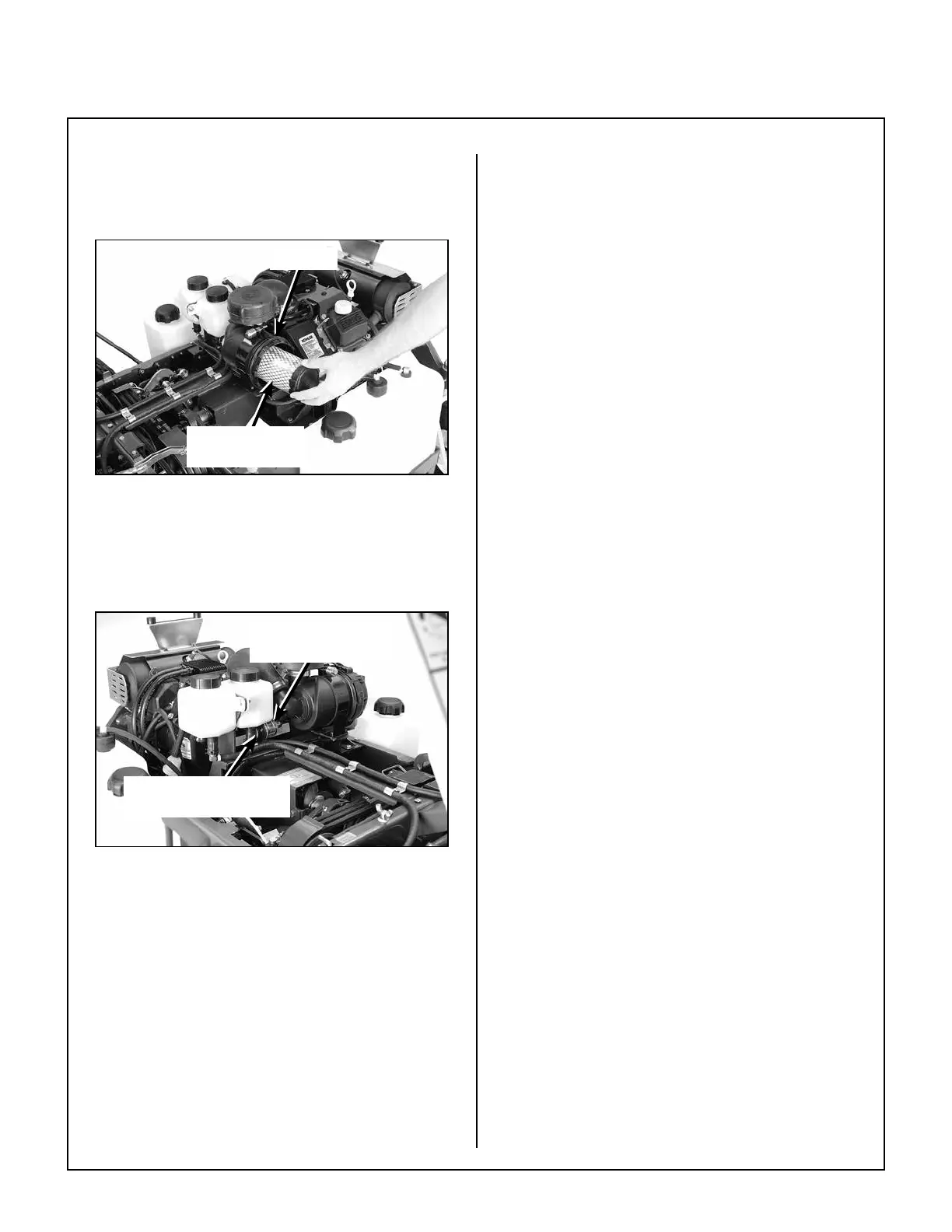

Push Button to Reset

Indicator After Service

Air Filter

Restriction Gauge

Air Filter Restriction Gauge Location

Inspect the primary lter element after every 100

hours of service and replace the element and safety

lter yearly (or when dirty or damaged). More fre-

quent replacement may be required when operating

in extremely dusty conditions as indicated by the air

lter restriction gauge. Service the air cleaner as

follows:

1. Lift Mono Latch Twist Lock™ and twist the

OptiAir™ cover to the left into the “open” position

to remove the air cleaner cover. Wash the cover

and dust ejection valve. Check that these

components are in good condition. The dust

ejection valve is subject to wear and deterioration

and should be replaced yearly or when

damaged. The lips of the valve should close and

t together; any cracks, deformation, or wear in

the valve is cause for replacement.

2. Remove the primary lter element by pulling it out

of the canister. There will be some initial resis-

tance as the lter seal breaks loose and slides off

of the outlet tube. Gently move the end of the

lter up and down and side to side or twist to

loosen the seal. Use gentle action to minimize

the amount of dust dislodged as the lter is re-

moved.

3. Replace the primary lter element.

NOTE: Washing the element in water or clean ing

solution is not recommended. Do not try to

clean the element with compressed air.

4. Use a bright light inside the primary lter element

to inspect for damage. Check the element very

carefully for pin holes or other damage that will

allow dirt to leak through the paper media. Re-

place element if necessary.

5. Without removing, visually inspect the condition

of the safety lter for damage or holes. The

safety lter should only be removed for yearly

replacement (or when dirty or damaged).

6. Check the condition and resilience of the radial

sealing surface (inside of the open end) of the

primary lter element. Replace the element if any

cracks, tears, or other damage to the sealing sur-

face are noted.

7. Use a clean, damp cloth and wipe the interior of

the air cleaner canister clean. Use special care

to clean both the inside and outside surfaces

of the outlet tube.

IMPORTANT: Any dust left on the inside of the

outlet tube will go into the engine and cause wear.

8. Check the outside surface of the outlet tube for

smoothness and cleanness (this is the sealing

surface).

Loading...

Loading...