56

Maintenance Instructions CHECKING/SERVICING

4. If the blade cutting edge is dull or nicked, it

should be sharpened. Remove blades for sharp-

ening by grasping the end of the blade using a

rag or a thick, padded glove, while loos ening and

removing the bolt and washer that mounts the

blade.

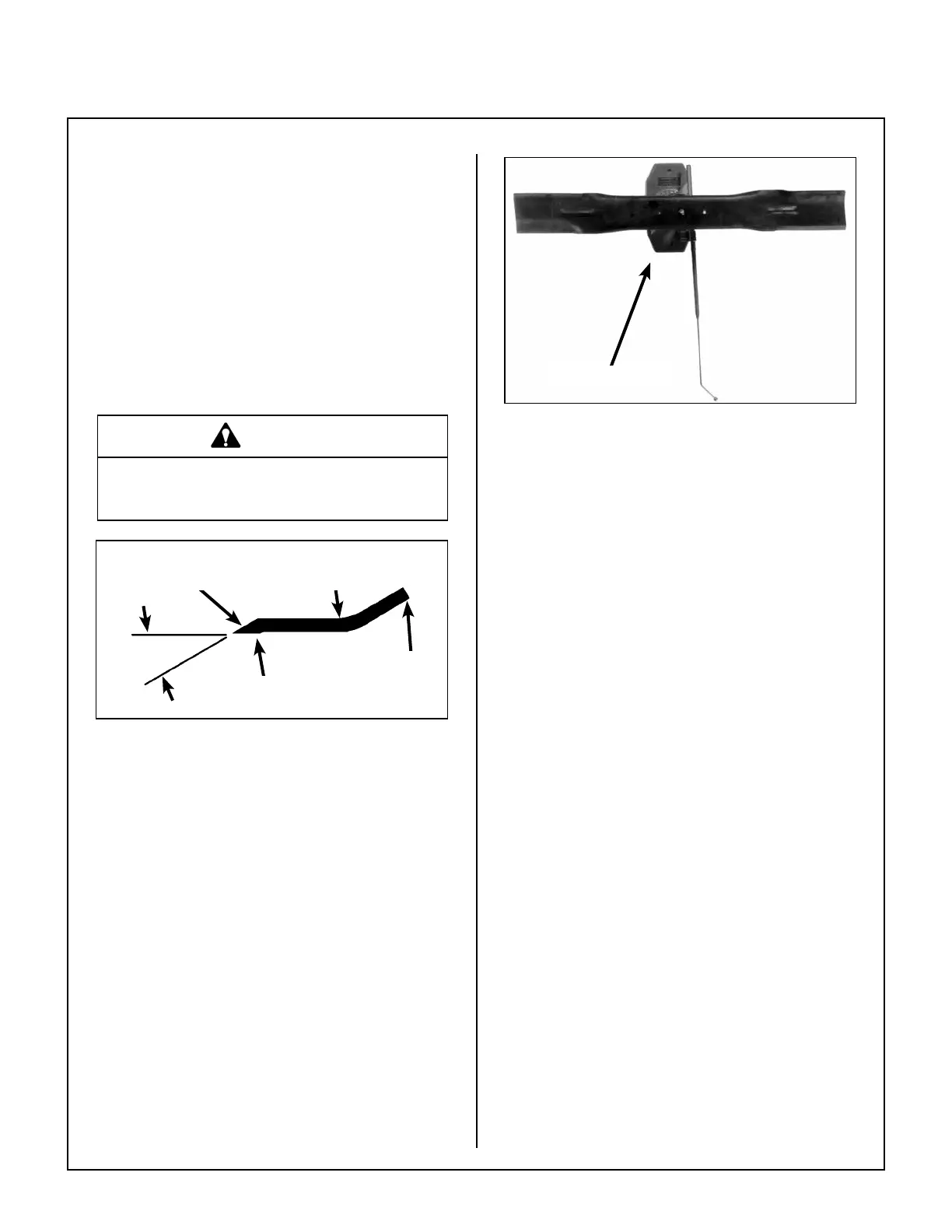

5. Grind cutting edge at the same bevel as the orig-

inal. Sharpen only the top of the cutting edge to

maintain sharpness.

NOTE: Blades can be sharpened with an electric

blade sharpener, conventional electric grinder, or

a hand le.

CAUTION

ALWAYS wear eye protection and gloves

when sharpening a blade.

Sharpen at Original

30° Angle

Intersection

Wear Area

Do Not Grind or

Sharpen on Underside

30°

Wing Tip

Mower Blade Prole for Sharpening

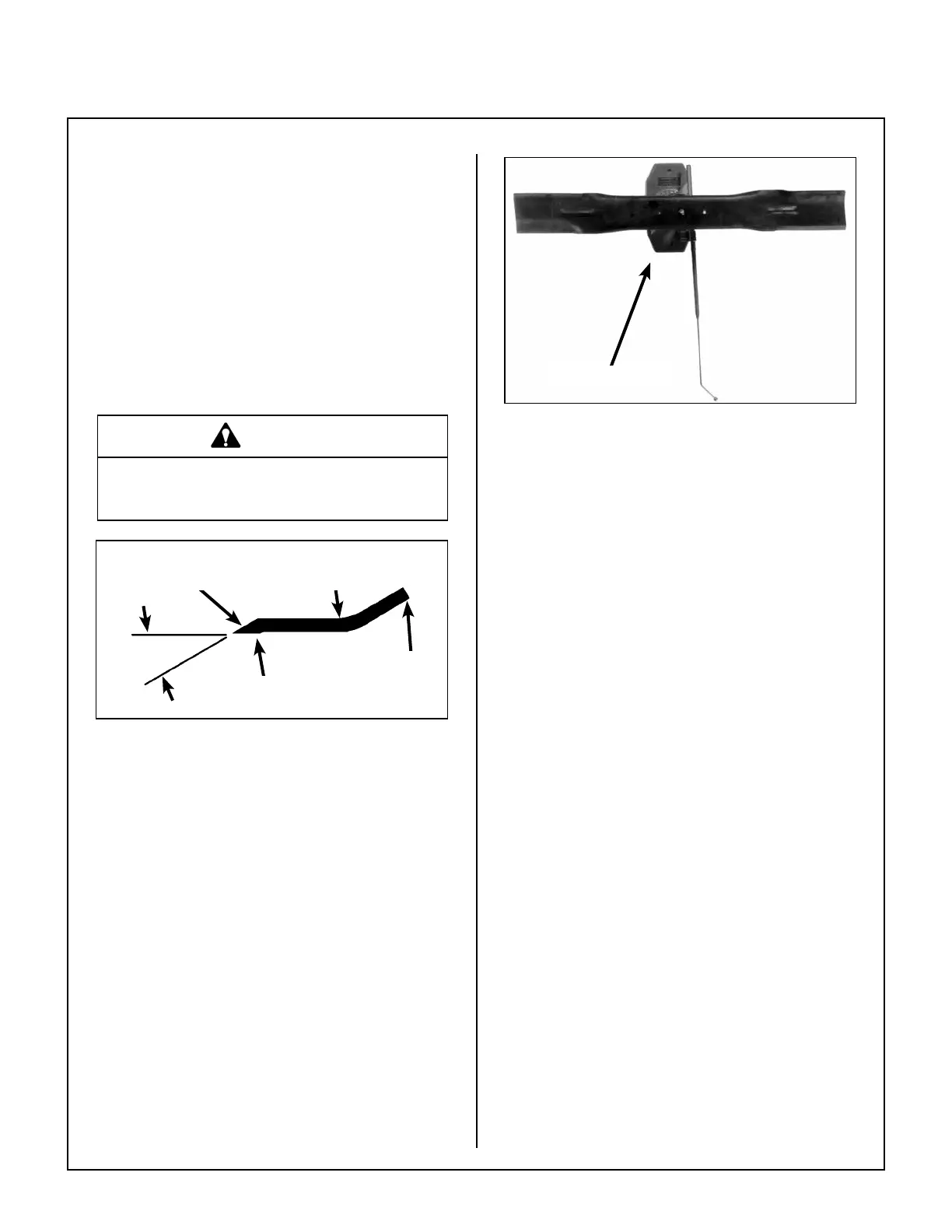

6. Check blade balance by positioning the blade

horizontally on a blade balancer or use a nail or

shaft through the center hole. If either end of the

blade rotates downward, grind (remove) metal

on that end until the blade will balance. The

blade is properly balanced when neither end

drops. Balance of a blade is generally main-

tained by removing an equal amount of material

from each end of the blade when sharpening.

Blade Balancer

Blade Balanced on Magnetic

Wall-Mounted Balancer

7. Mount the blade with wing tips pointing up into

the housing. Reinstall the blade, washer, and

bolt. Tighten the bolt to 64 lb·ft (87 N

·m).

Drive Belts

Raise the body and inspect the condition of the four

(4) drive belts after every 25 hours of operation --

engine/PTO drive (3) and ground drive (1). If the belts

show signs of cracking or deteriorating, the belts

should be replaced. Refer to REPLACING/REPAIR-

ING the Drive Belts in this section.

Spark Plugs

Every 200 hours, remove the spark plugs, inspect,

clean, and reset the gap (or replace with a new plug).

Clean spark plug with a wire brush. If the electrodes

are burned short or pitted, replace the plug (refer to

Specications for the proper type of replacement

plug). Check the spark plug gap with a wire-type

feeler gauge and set the gap to 0.030 in. (0.76 mm).

Reinstall and tighten to 18 lb·ft (24 N·m). Both spark

plugs should be replaced yearly.

Ignition Wires

Good preventive maintenance calls for complete re-

placement of spark plug wires every two (2) years.

Loading...

Loading...