Maintenance Instructions LUBRICATION

51

Changing Engine Crankcase Oil

Change the engine crankcase oil after every 100

hours of operation as follows:

1. Park the mower on a level surface with the

en gine stopped. The engine oil should be

warm before draining. If not warm from opera-

tion, start the engine and run a few minutes to

warm the oil.

2. Before removing the dipstick, clean the area

around the dipstick to keep any dirt or debris out

of the en gine.

3. Remove the dipstick and the oil drain plug and

drain the oil into a suitable container. Be sure

to allow ample time for complete drainage.

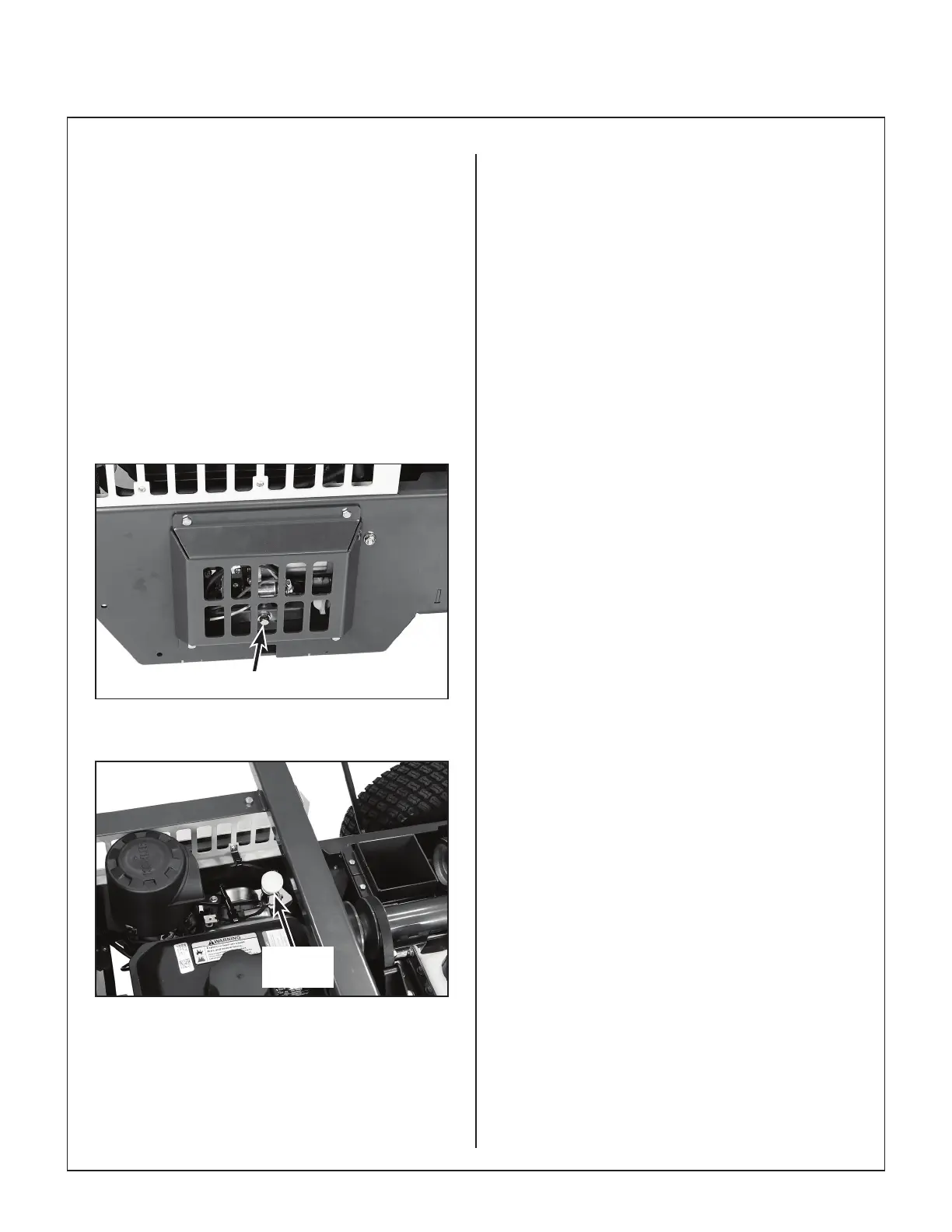

Oil Drain

Oil Drain Location

(View from Lower Right Side of Tractor)

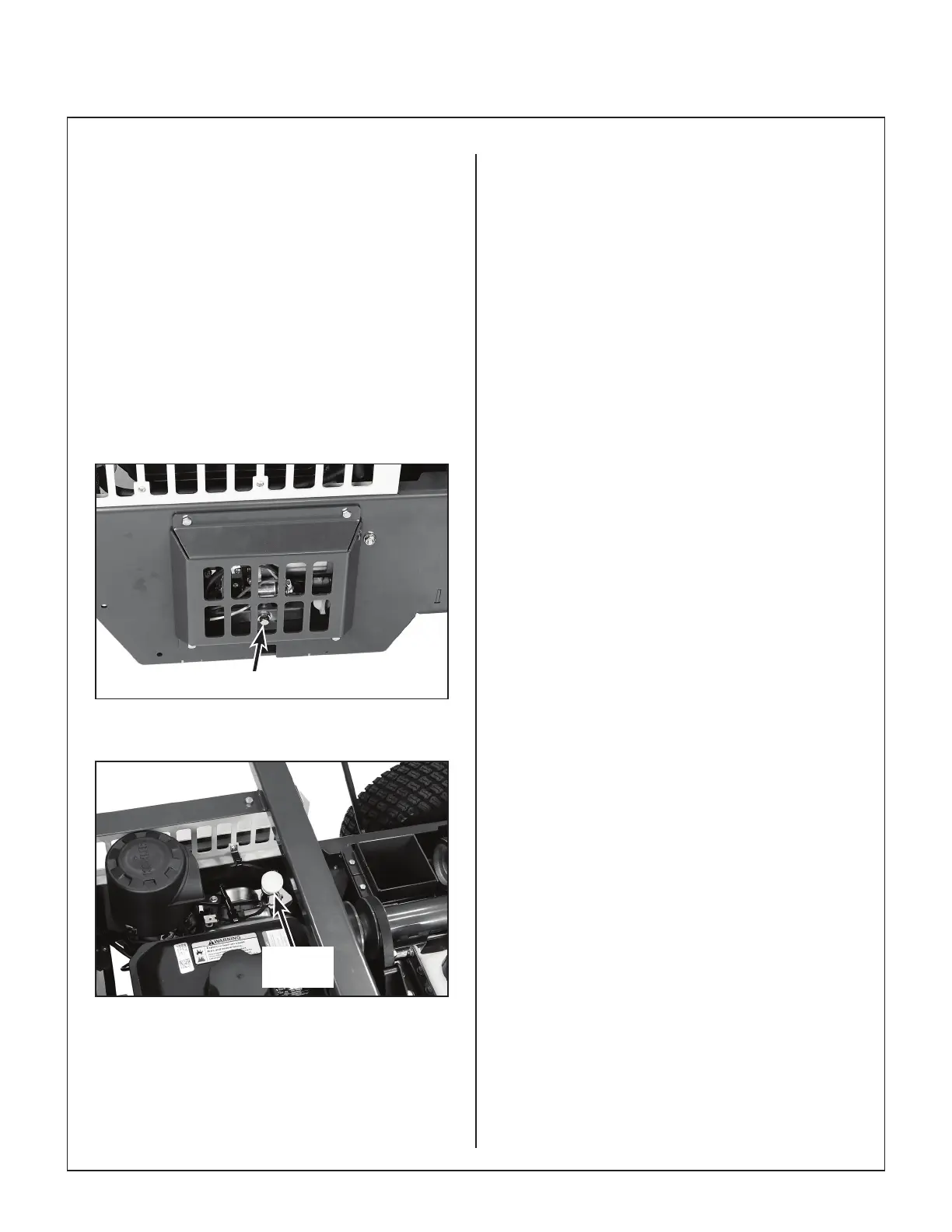

Dipstick

(Oil Fill)

Dipstick (Oil Fill) Location

(View from Above Right Side of Tractor)

4. Reinstall the drain plug. Make sure it is tight-

ened to 13 lb

·ft (17.6 N·m).

5. Fill the crankcase (through the dipstick tube)

with new, clean oil. Use only crankcase lubri-

cants recommended by the engine manufac-

turer. Refer to Specications in this manual or

the engine owner’s manual. Use the recom-

mended oil viscosity for the expected ambient

temperature. Oil with the correct viscosity will

aid starting in cold weather and assure proper

lubrication in hot weather. Fill to FULL (F)

mark on the dipstick; crankcase capacity is 1.2

quarts (1.1 liters).

IMPORTANT: Check the dipstick reading be-

fore adding the last 1/2 pint of oil and ll only to

the FULL (F) mark. The oil level should never

be over the FULL (F) mark on the dipstick; over-

lling can result in engine overheating and loss

of power.

6. Start and run the engine. Stop the engine, re-

check the oil level, and add oil if necessary.

Grease Fitting and Oil Point Lubrication

Lubricate the grease ttings and oil points after ev-

ery 25 hours of operation. Lubricate more often

when operating in dusty or dirty conditions. Use

SAE general purpose lithium or molybdenum base

grease for grease ttings and light machine oil

(SAE 10) to lubricate oil points. Lubricate the

locations shown in the Chassis and Deck

Lubrication Points illustration.

NOTE: PTO universal joints (on the deck and trac-

tor) require routine lubrication after every 25

hours of running time. Refer to PTO U-Joint Lu-

brication (Tractor) in this section for lubricating U-

Joint on tractor.

NOTE: The ball bearings on the PTO drive shaft are

sealed and do not require periodic maintenance.

Loading...

Loading...