9.4 Grease Points

IMPORTANT! Do not over grease. Too much grease can

cause the bearing seals to fail.

Look for this decal on the machine. It

indicates a grease point and the interval in

hours.

• Use a hand-held grease gun for all greasing. Apply one

pump per location.

• Wipe each grease fitting with a clean cloth before greasing

to avoid injecting dirt and grit.

• Replace or repair broken fittings immediately.

• If a fitting does not take grease, remove and clean the

fitting thoroughly. Also, clean the lubricant passageway. If

required, replace the fitting.

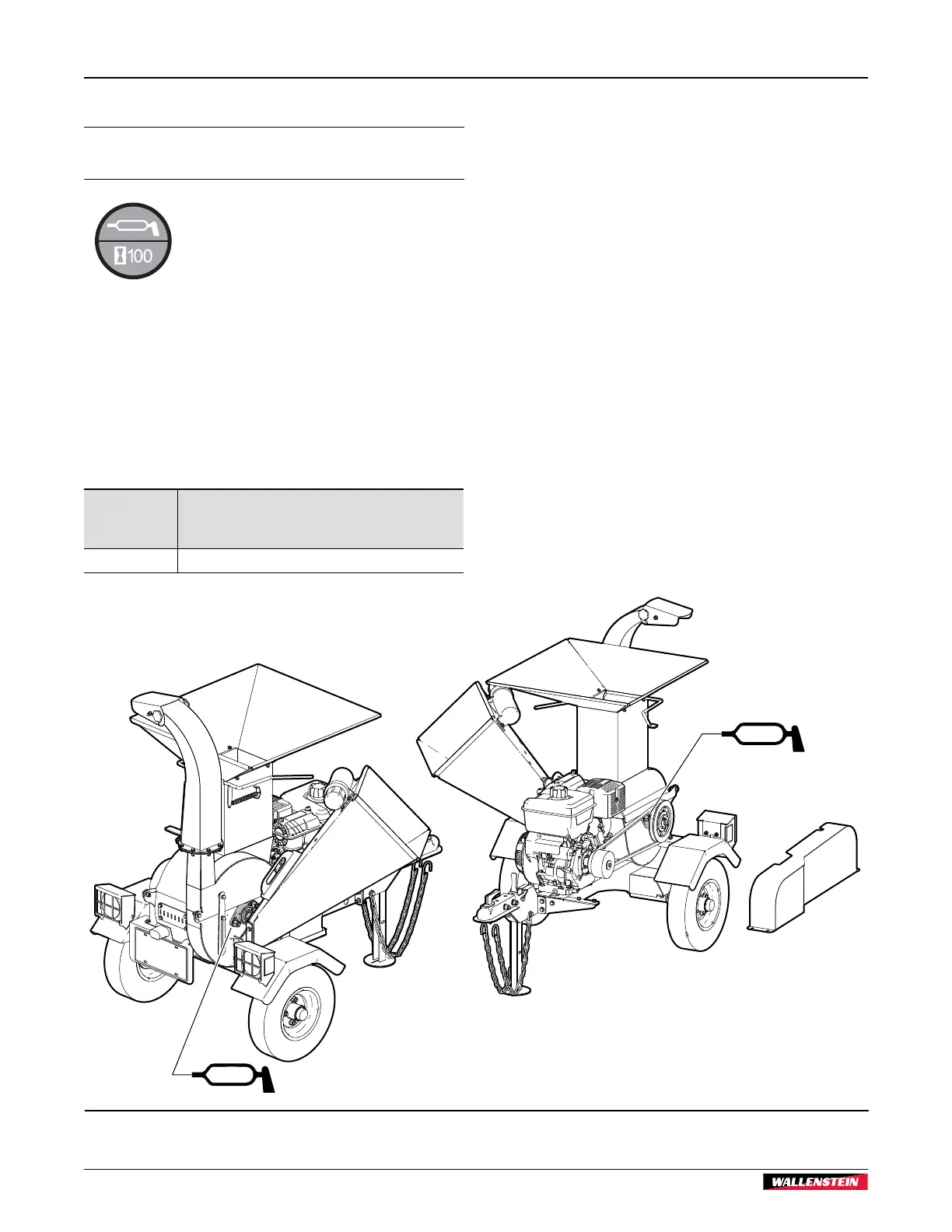

Location

Every 100 hours of operation or

annually

1 Rotor bearings, one pump on each side.

01935

1

1

Fig. 37 – Grease points

Service and Maintenance

BXMT3213

Trailer Chipper / Shredder

38

Loading...

Loading...